Synthesis method of clodinafop-propargyl

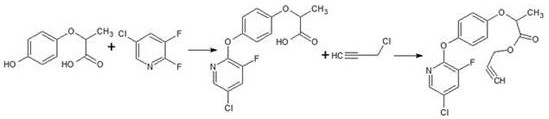

A synthetic method, the technology of clodinafop-propargyl, which is applied in the field of synthesis of clodinafop-propargyl, can solve the problems of affecting the quality of clodinafop-propargyl products, low synthesis efficiency, cumbersome synthesis steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0018] Dissolve 72.9g (0.4mol) DHPPA in 200g acetonitrile, stir and heat up, add 0.3g sodium sulfite and 55g (0.97mol) KOH at 50°C, and start adding 66g of 2,3-difluoro-5-chloropyridine dropwise when the temperature rises to 60°C (0.44mol), after the dropwise addition, the temperature was raised to 70°C for 5 hours. After the heat preservation, remove acetonitrile under reduced pressure, add 200g of water after removing acetonitrile, add dropwise hydrochloric acid with a mass fraction of 30% to adjust pH = 1, cool and precipitate, filter, and wash with water to obtain a dry etherified product: 124.6g.

[0019] Feed 62.3g (about 0.2mol) of ether compound and 82g of DMF into a 500mL four-necked bottle and heat up until the material is completely dissolved. Add 30g (0.22mol) of potassium carbonate and heat up to 60°C. Add 20g (0.27mol) of propyne chloride dropwise. Finish at 65°C for 4 hours. Heat preservation finishes adding water 100g, toluene 130g, stirring and dissolving, st...

Embodiment approach 2

[0021] Dissolve 72.9g (0.4mol) of DHPPA in 200g of acetonitrile, stir and heat up, add 0.3g of sodium sulfite and 53.3g (0.95mol) of KOH at 50°C, and start adding 2,3-difluoro-5-chloropyridine dropwise when the temperature rises to 60°C 66g (0.44mol), the dropwise addition was completed and the temperature was raised to 70°C for 5 hours. After the heat preservation is over, remove acetonitrile under reduced pressure, add 200 g of water after removing the acetonitrile, add dropwise hydrochloric acid with a mass fraction of 30% to adjust pH = 1, cool and precipitate, filter, and wash with water to obtain a dry etherified product: 124 g.

[0022] Feed 62g (about 0.2mol) of ether compound and 82g of DMF into a 500mL four-necked bottle and heat up until the material is completely dissolved. Add 30g (0.2mol) of potassium carbonate and heat up to 60°C. Add 20g (0.27mol) of propyne chloride dropwise, and the addition is completed Incubate at 65°C for 4 hours. Heat preservation finish...

Embodiment approach 3

[0024] Dissolve 72.9g (0.4mol) of DHPPA in 200g of acetonitrile, stir and raise the temperature, add 0.3g of sodium sulfite and 56.1g (1mol) of KOH at 50°C, and start adding 2,3-difluoro-5-chloropyridine 74.7 dropwise at 60°C g (0.5mol), after the dropwise addition, the temperature was raised to 70°C for 6 hours. After the heat preservation is over, remove acetonitrile under reduced pressure, add 200 g of water after removing the acetonitrile, add dropwise hydrochloric acid with a mass fraction of 30% to adjust the pH to 1, cool and precipitate, filter, and wash with water to obtain a dry etherified product: 130 g.

[0025] Feed 65g (about 0.2mol) of ether compound and 82g of DMF into a 500mL four-necked bottle and heat up until the material is completely dissolved. Add 30g (0.22mol) of potassium carbonate and heat up to 60°C. Add 20g (0.27mol) of propyne chloride dropwise, and the addition is completed Incubate at 65°C for 4 hours. Heat preservation finishes adding water 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com