Preparation method of weather-resistant advertising car sticker for outdoor use

A weather-resistant, advertising vehicle technology, used in film/sheet adhesives, non-polymer adhesive additives, adhesive types, etc. Unsatisfactory performance and other problems, to achieve the effect of improving waterproof performance, stable bonding and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

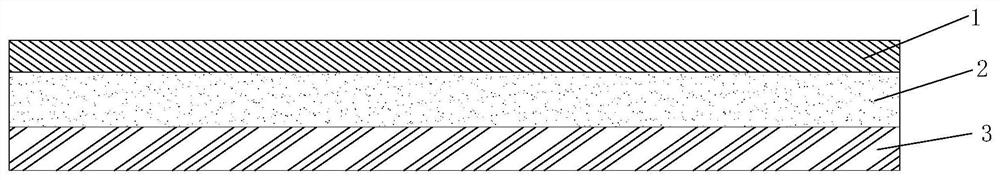

[0022] Embodiment 1~4: A kind of preparation method of weather-resistant advertising car sticker for outdoors, comprises base material layer 1, back glue layer 2 and release layer 3, one side of described base material layer 1 is coated on back glue layer 2. The side of the adhesive layer 2 facing away from the substrate layer 1 is provided with a release layer 3, and the adhesive layer is obtained by coating and drying the adhesive solution, which is prepared by the following steps:

[0023] S1. Mix 15~25 parts of methyl methacrylate, 15~25 parts of styrene, 15~20 parts of 2-ethylhexyl acrylate, 1~1.5 parts of trimethylpentanediol, and 1 part of dimethylaminopropionitrile ~5 parts and 50~75 parts of deionized water are mixed evenly, and the temperature is raised to 75~80°C, and 0.5~1.5 parts of azoisobutylcyanoformamide and 1~10 parts of acrylic acid are added dropwise to the mixed system, and the reaction is 3~ 4h;

[0024] S2. Cool to room temperature, add 1-5 parts of bis...

Embodiment 1

[0028] In Example 1, the addition ratio of methyl methacrylate to styrene is 1:1, the above-mentioned curing agent is selected from the curing agent S01-5, the above-mentioned emulsifier is selected from the ethoxylated C16-18-alcohol, and the above-mentioned substrate layer It is a PVC layer, the thickness of the above-mentioned substrate layer is 70 μm, and the thickness of the above-mentioned back glue layer is 15 μm.

Embodiment 2

[0029] In Example 2, the addition ratio of methyl methacrylate to styrene is 2:1, the above-mentioned curing agent is selected from the curing agent MH2844, the above-mentioned emulsifier is selected from glyceryl polyethylene oxide, and the above-mentioned substrate layer is a PVC layer. The thickness of the base material layer is 120 μm, and the thickness of the back adhesive layer is 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com