Method and device for preparing mixed rare earth chloride through continuous extraction transformation of sulfuric acid rare earth

A technology of rare earth sulfate and rare earth chloride, applied in the direction of improving process efficiency, etc., can solve the problems of low automation, poor sealing of cylindrical reaction tanks, high labor operation intensity, etc., achieve high automation and improve the operating environment and labor intensity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

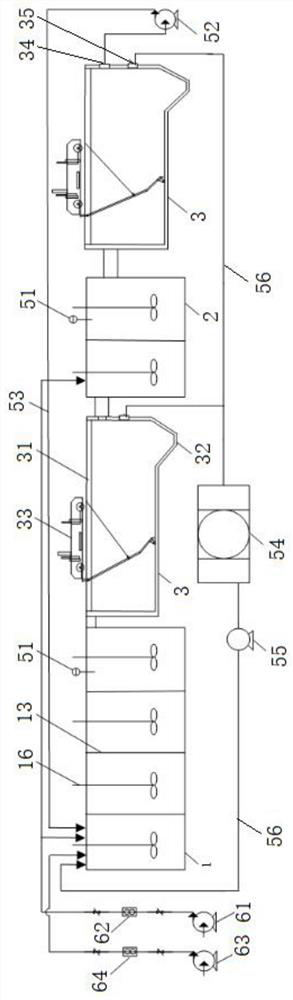

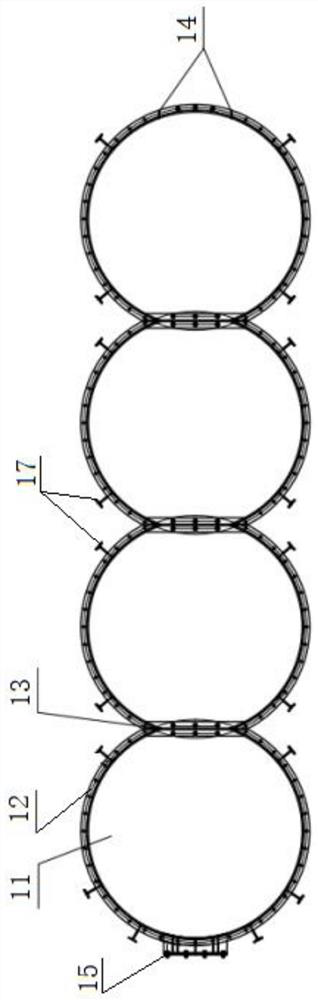

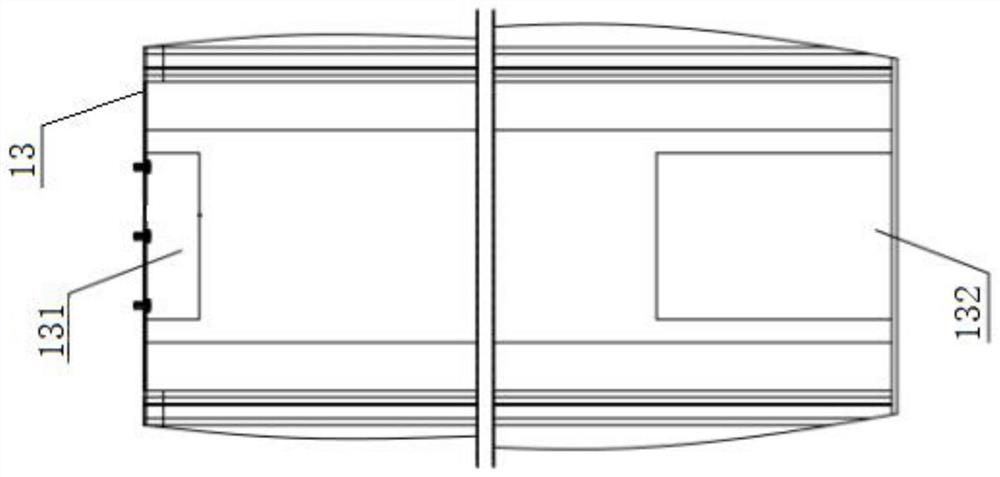

[0068] n=4, m=2, a total of 6 stages of continuous transformation tanks.

[0069] Rare earth sulfate solution REO=26g / L, pH=4.5, solution temperature 45°C. Given flow 96m 3 / h, start the agitation of the 1st to 6th stage agitator 16 from back to front, the rare earth sulfate solution is fed by the flow control system, and the saponified organic phase is controlled according to the calculation flow input. First, the organic phase and the aqueous phase all enter the first stage transformation Single tank 11, the solution after the reaction flows into the next stage transformation single tank 11 step by step, the clarified water phase containing ammonium sulfate, magnesium sulfate or other sulfates flows out from the water phase overflow port 35, and is regulated according to the pH meter 51 The amount of rare earth sulfate solution to be added is to control the pH=4.5-5.5 to ensure that the aqueous phase of ammonium sulfate, magnesium sulfate or other sulfates does not contain ...

Embodiment 2

[0072] n=4, m=2, a total of 6 stages of continuous transformation tanks.

[0073] Rare earth sulfate solution REO=30g / L, pH=4.5, solution temperature 45°C. Given flow rate 83.2m 3 / h, start the agitation of the 1st to 6th stage agitator 16 sequentially from back to front, the rare earth solution is fed by the flow control system of the feed liquid, and the saponified organic phase is input according to the calculation control flow rate. First, all the organic phase and the aqueous phase enter the first stage. The step-by-step conversion single tank 11, the solution after the reaction flows into the next-level conversion single tank 11 step by step, and the water phase containing ammonium sulfate, magnesium sulfate or other sulfates after clarification flows out from the water phase overflow port 35, according to the pH meter 51 To regulate the addition of rare earth sulfate solution, control pH=4.5-5.5 is used to ensure that the aqueous phase of ammonium sulfate, magnesium su...

Embodiment 3

[0076] n=4, m=2, a total of 6 stages of continuous transformation tanks.

[0077] Rare earth sulfate solution REO=35g / L, pH=4.5, solution temperature 45°C. A total of 6 stages of continuous transition tanks, with a given flow rate of 72m 3 / h, start the agitation of the 1st to 6th-stage agitator 16 from back to front, the rare earth solution is fed by the feed liquid flow control system, and the saponified organic phase is input according to the calculated flow control. First, the organic phase and the aqueous phase all enter the first stage Transformation single tank 11, the solution after the reaction flows into the next stage transformation single tank 11 step by step, and the water phase containing ammonium sulfate, magnesium sulfate or other sulfates after clarification flows out from the water phase overflow port, according to pH meter 51 Regulating the amount of rare earth solution added, controlling the pH=4.5-5.5 is used to ensure that the aqueous phase of ammonium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com