Degradable tow with O-shaped sheath-core structure for cigarette filter tip and preparation method of degradable tow

A skin-core structure and filter technology, which is applied in the field of degradable tow preparation, can solve the problems of environmental pollution, thermal stability and poor adhesion, and achieve the effects of simple preparation process, easy operation and improved environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a degradable tow with an O-shaped skin-core structure for a cigarette filter, comprising the following steps:

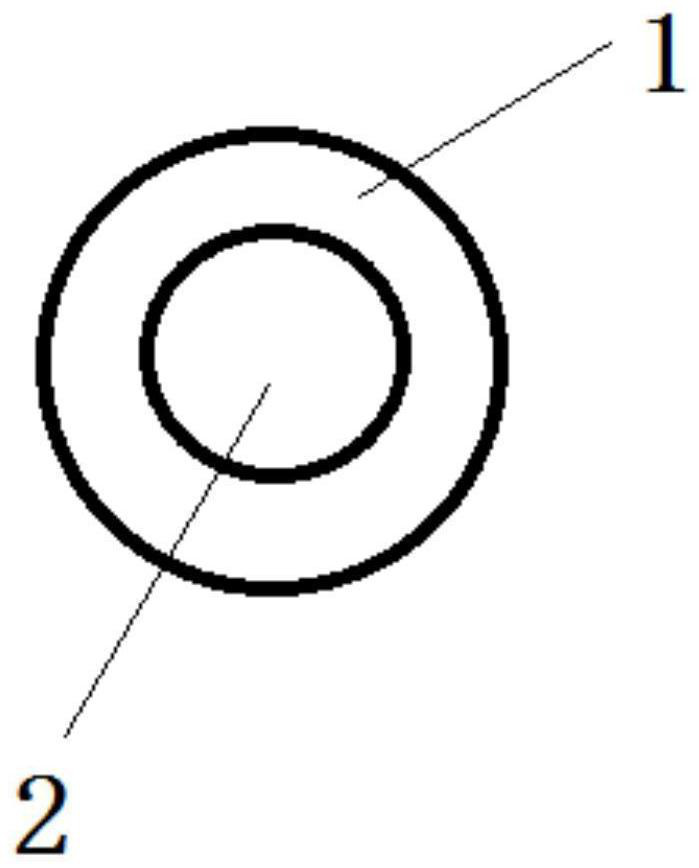

[0038] Put PBAT resin as the core layer resin in an oven at 90°C for 12 hours, and PBS resin as the skin layer resin in an oven at 80°C for 12 hours. The weight ratio of the skin layer to the core layer is 1:1. Then add materials into different twin-screw extruders respectively. The core layer twin-screw temperature is set at 120°C-140°C-160°C-140°C-130°C, and the filtration temperature is 165°C. Cortex twin-screw 120°C-130°C-150°C-140°C-130°C, filtration temperature 155°C. The diameter of the spinneret is 200 mm, the spinneret holes are O-shaped, and the number of holes is 1200. Then through drawing, crimping, drying to get such as figure 1 tow shown. The obtained tow is thermally bonded at 120° C. for 3 seconds and then shaped by a filter rod forming machine through a forming process to obtain a cigarette filter rod.

Embodiment 2

[0040] A method for preparing a degradable tow with an O-shaped skin-core structure for a cigarette filter, comprising the following steps:

[0041] Put PBS resin as the core layer resin in an oven at 85°C for 12 hours, and PBSA resin as the skin layer resin in an oven at 80°C for 12 hours. The weight ratio of the skin layer to the core layer is 1:0.5. Then add materials into different twin-screw extruders respectively. The core layer twin-screw temperature is set at 120°C-130°C-150°C-140°C-130°C, and the filtration temperature is 160°C. Cortex twin-screw 120°C-130°C-150°C-140°C-130°C, filtration temperature 160°C. The diameter of the spinneret is 200 mm, the spinneret holes are O-shaped, and the number of holes is 1500. Then through drawing, crimping, drying to get such as figure 1 tow shown. The obtained tow is thermally bonded at 110° C. for 5 seconds and then shaped by a filter rod forming machine through a forming process to obtain a cigarette filter rod.

Embodiment 3

[0043] A method for preparing a degradable tow with an O-shaped skin-core structure for a cigarette filter, comprising the following steps:

[0044] Put PBAT resin as core layer resin into 80 ℃ oven and dry for 12h, PBS and PBSA resin (wherein the mass fraction of PBS and PBSA are 50%) put into 80 ℃ oven for 12h as cortex resin, wherein the weight of cortex and core layer The ratio is 1:0.7. Then add materials into different twin-screw extruders respectively. The core layer twin-screw temperature is set at 120°C-140°C-160°C-140°C-130°C, and the filtration temperature is 165°C. Cortex twin-screw 120°C-130°C-150°C-140°C-130°C, filtration temperature 150°C. The diameter of the spinneret is 200 mm, the spinneret holes are O-shaped, and the number of holes is 1000. Then through drawing, crimping, drying to get such as figure 1 tow shown. The obtained tow is thermally bonded at 120° C. for 5 seconds and then shaped by a filter rod forming machine through a forming process to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com