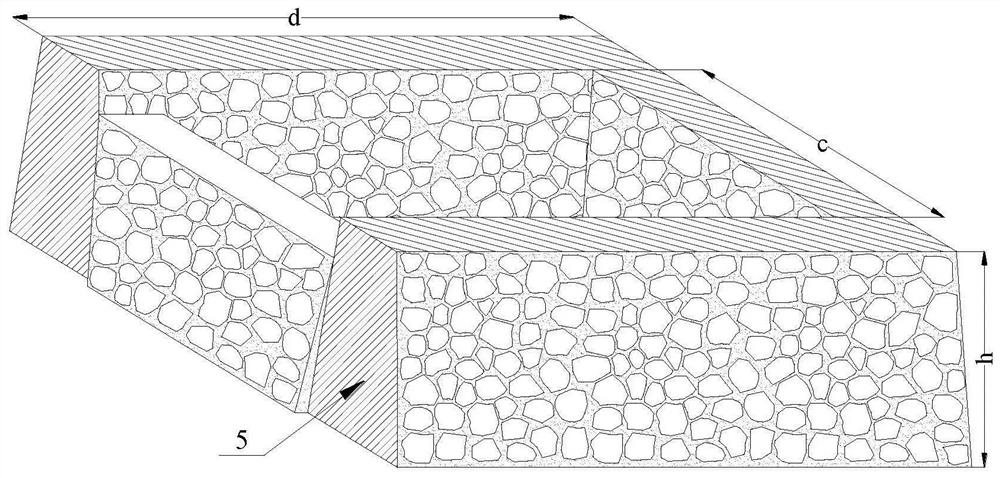

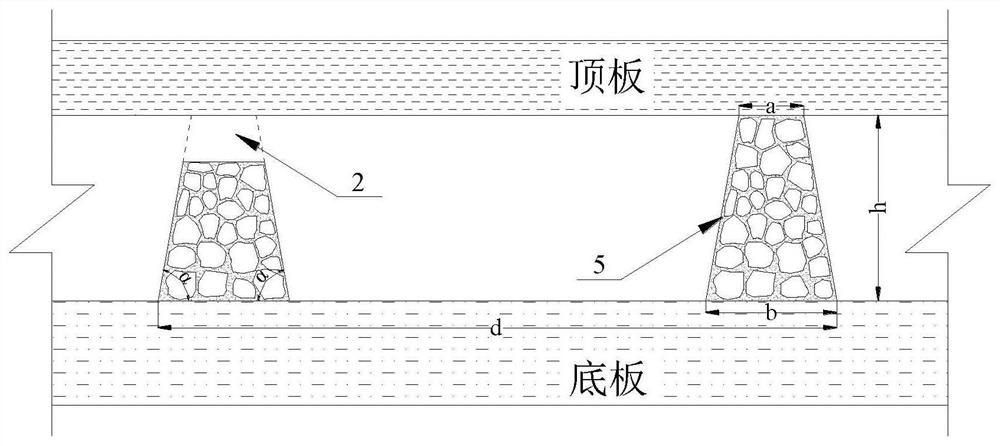

Method for full roof-contacted filling of gangue in well mining goaf

A goaf and gangue technology, applied in the fields of backfill, mining equipment, earth-moving drilling, etc., can solve the problems of unreasonable filling equipment and process, affecting the degree and quality of roofing, and easy sliding of gangue. The effect of gangue compaction filling and topping, improving compaction quality and efficiency, avoiding economic and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

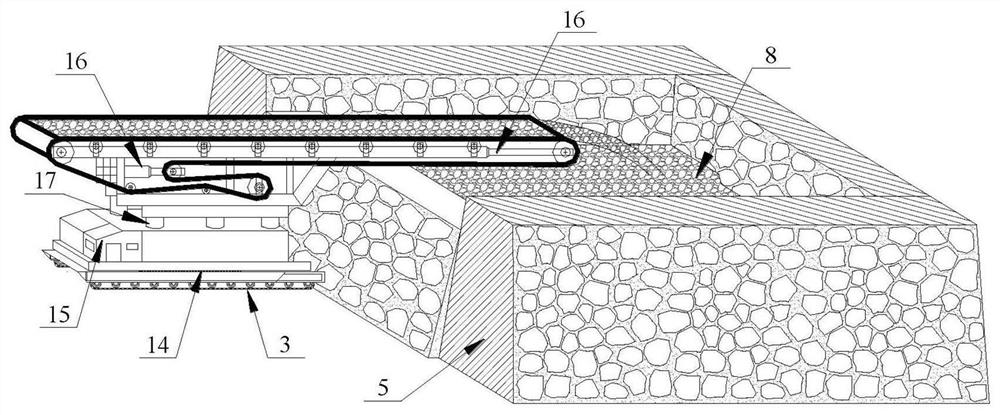

Method used

Image

Examples

Embodiment

[0048] A coal mine recovers part of the coal resources under the village buildings. The conditions for the occurrence of this part of coal are: the mining depth is 320.0m, the coal seam is nearly horizontal, and the thickness of the coal seam is 3.8m. This part of the coal resource is recovered by using the room-type coal mining method. The relevant parameters are: mining height h=3.8m, 7 coal rooms, 3 roadways for preparation, width of each coal room f=6.0m, connection between adjacent coal rooms The width of the roadway is L=6.0m, the size of the coal pillars left is m×n=7.0m×7.0m, the length of the coal room in the advancing direction is 156.0m, the width of the preparation roadway is u=5.0m, and the width of the connecting roadway between the preparation roadways is v=5.0 m, the distance between adjacent preparation roadways j=10.0m, and the distance between adjacent connecting roadways between preparation roadways k=15.0m. In order to improve the recovery rate of coal res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com