Safe operation system of heat exchanger of risers for coke oven

A technology for safe operation and heat exchangers, applied in indirect heat exchangers, heat exchanger types, heating of coke ovens, etc., can solve the problem of inability to accurately reflect the temperature of the inner cylinder, the inability to determine the actual temperature of the inner cylinder, and the inability to understand the rising pipe Heat exchanger leakage, dry burning and other problems, achieve high safety, increase buffer time, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

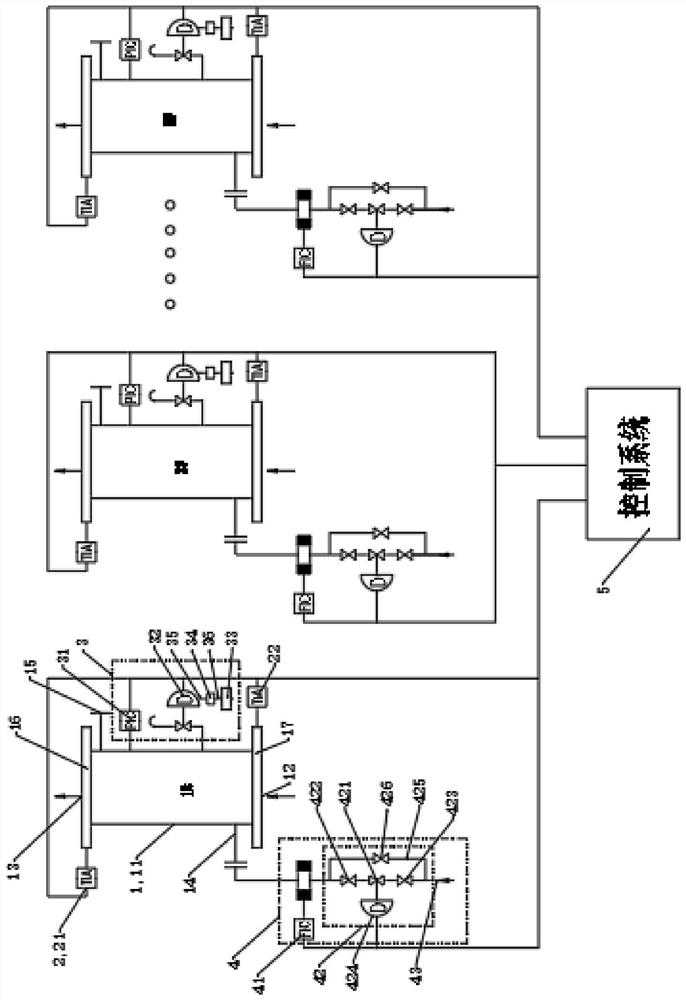

[0028] refer to figure 1 , a coke oven riser heat exchanger safe operation system, used to be installed on the riser 1 heat exchanger, including wall temperature monitoring device 2, over-temperature and over-pressure relief device 323, flow monitoring device 4 and control system 5;

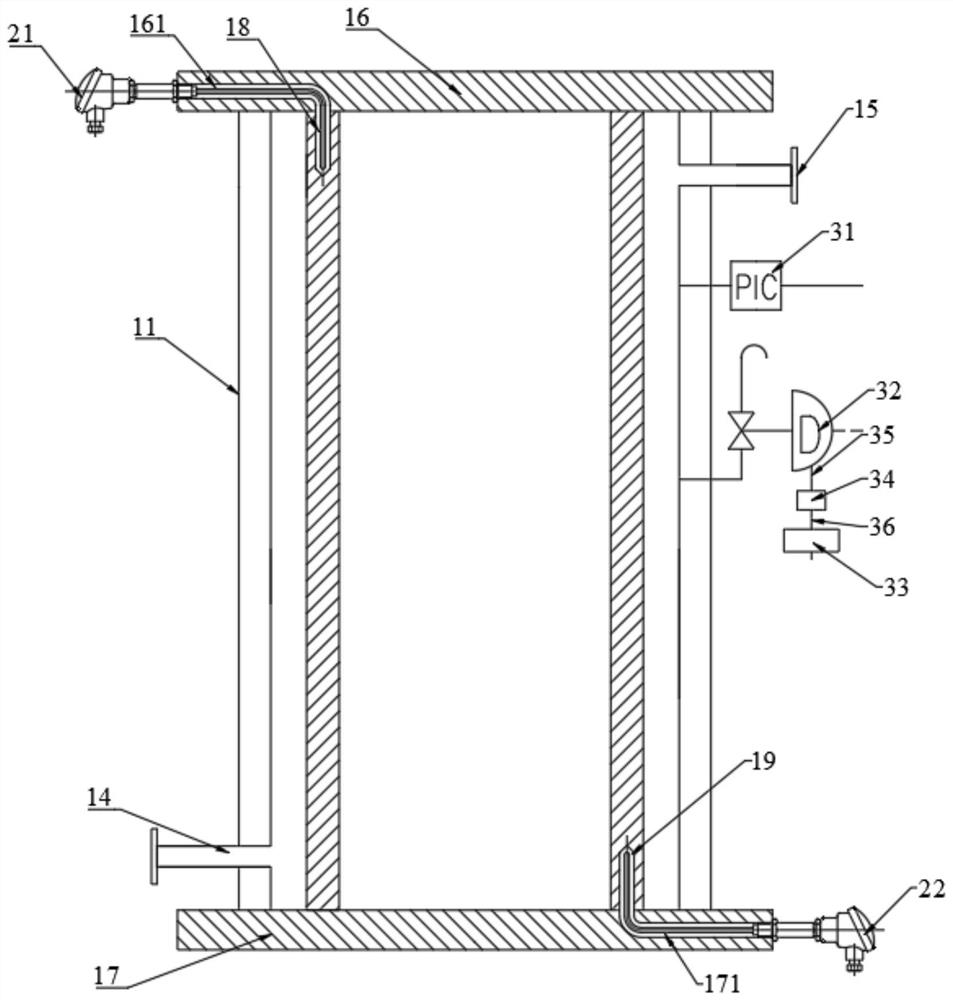

[0029] refer to figure 2 , the riser 1 heat exchanger includes a cylinder 11 with a certain wall thickness, a raw gas inlet 12, a raw gas outlet 13, a water inlet 14 and a water outlet 15, and an upper connecting flange 16 is provided above the cylinder 11 , the cylinder body 11 is lowered with a lower connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com