Composite energetic thin film semiconductor bridge

A thin-film semiconductor and semiconductor technology, applied in the direction of offensive equipment, blasting barrels, weapon accessories, etc., can solve the problems of easy oxidation, high temperature resistance, instability, etc., and achieve the effect of facilitating energy conversion and strong ignition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

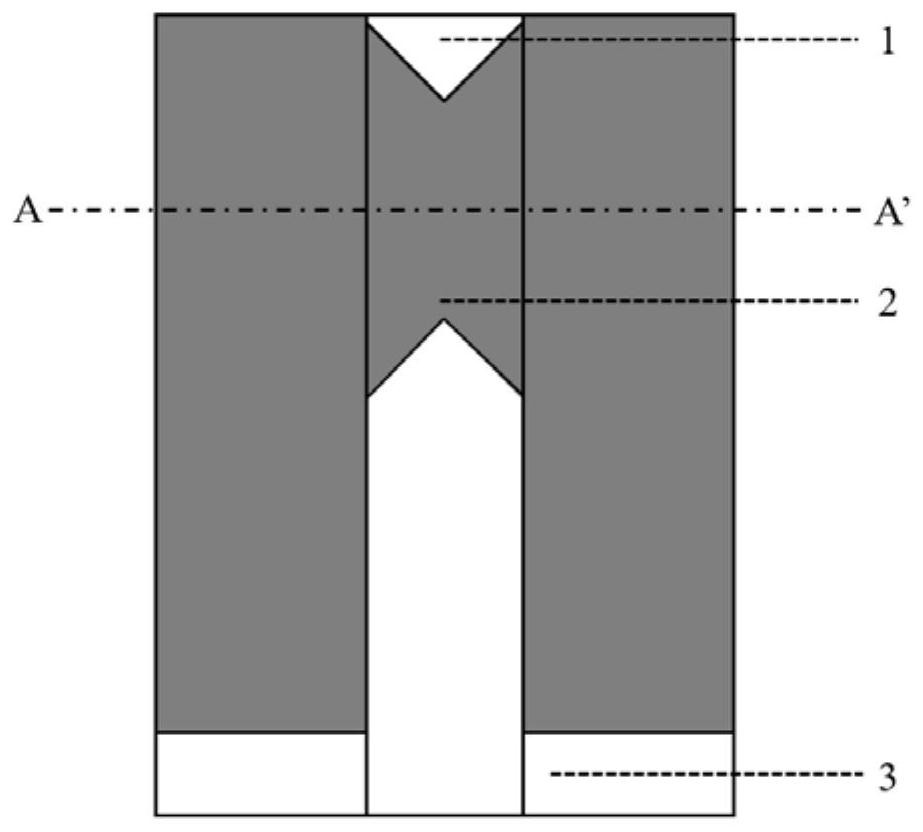

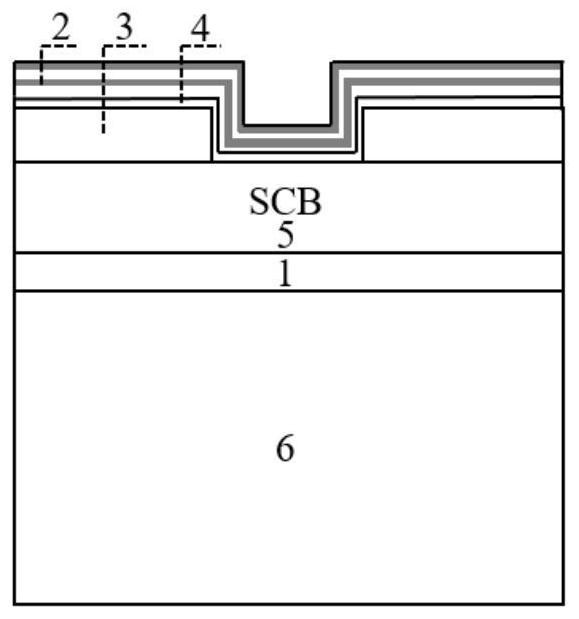

[0028] A compound energetic thin film semiconductor bridge, including a single crystal silicon substrate, SiO on the single crystal silicon substrate 2 Insulation layer, on SiO 2 Silicon ignition bridge region and aluminum electrode above thermal insulation layer, SiO over silicon ignition bridge region and aluminum electrode 2 insulating layer and sits on the SiO 2 The composite energetic thin film layer above the insulating layer, the material of the composite energetic thin film layer is B and Ti, and the thickness of the composite energetic thin film layer is 1 μm.

[0029] The preparation method of the above composite energetic thin film semiconductor bridge comprises the following steps:

[0030] Step 1, sputtering a 1 μm thick Al metal layer on the n-type semiconductor bridge substrate, and etching to form Al metal electrodes after photolithography.

[0031] Step 2, coating the substrate with the Al electrode obtained in step 1 with photoresist, pre-baking, alignment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com