A high-precision digital circular indexing sensor, system and detection method

A detection method and circular indexing technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of decreased measurement accuracy, low accuracy, measurement errors, etc., to improve accuracy, improve detection accuracy, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

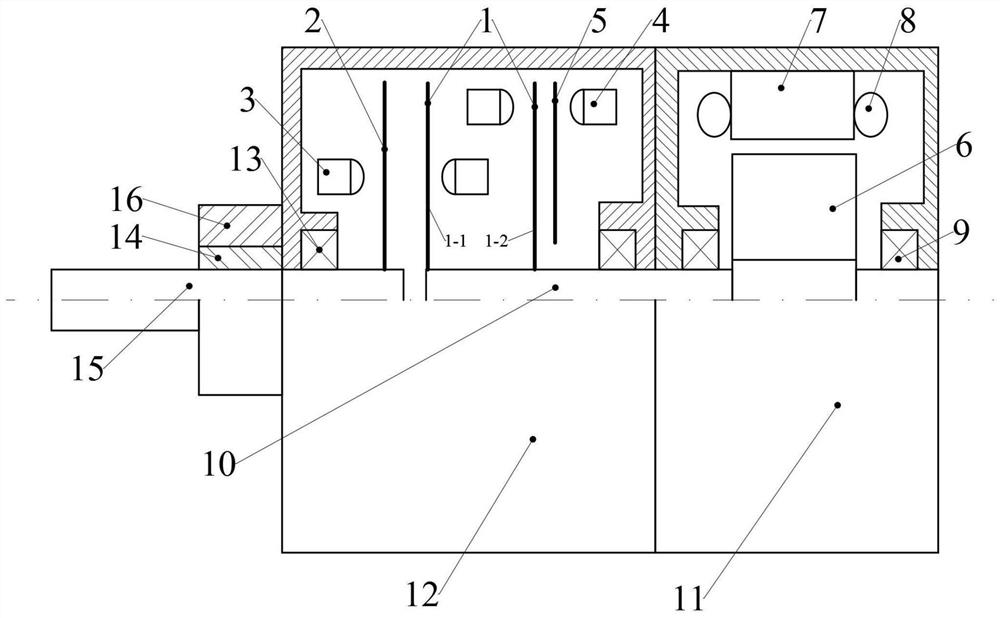

[0036] Such as figure 1 As shown, a high-precision digital circular indexing sensor includes a main grating group 1, a moving grating sheet 2, a moving photodiode pair 3, a static photodiode pair 4, a static grating sheet 5, a grating sensor housing 12, and a grating sensor bearing 13 , Detect the input shaft 15, the slip ring and the reference motor. The detection input shaft 15 is supported on the grating sensor housing 12 via the grating sensor bearing 13 . The reference motor is installed on the side of the grating sensor housing 12 away from the detection input shaft 15; The axis of the rotary shaft 10 coincides with the axis of the detection input shaft 15 .

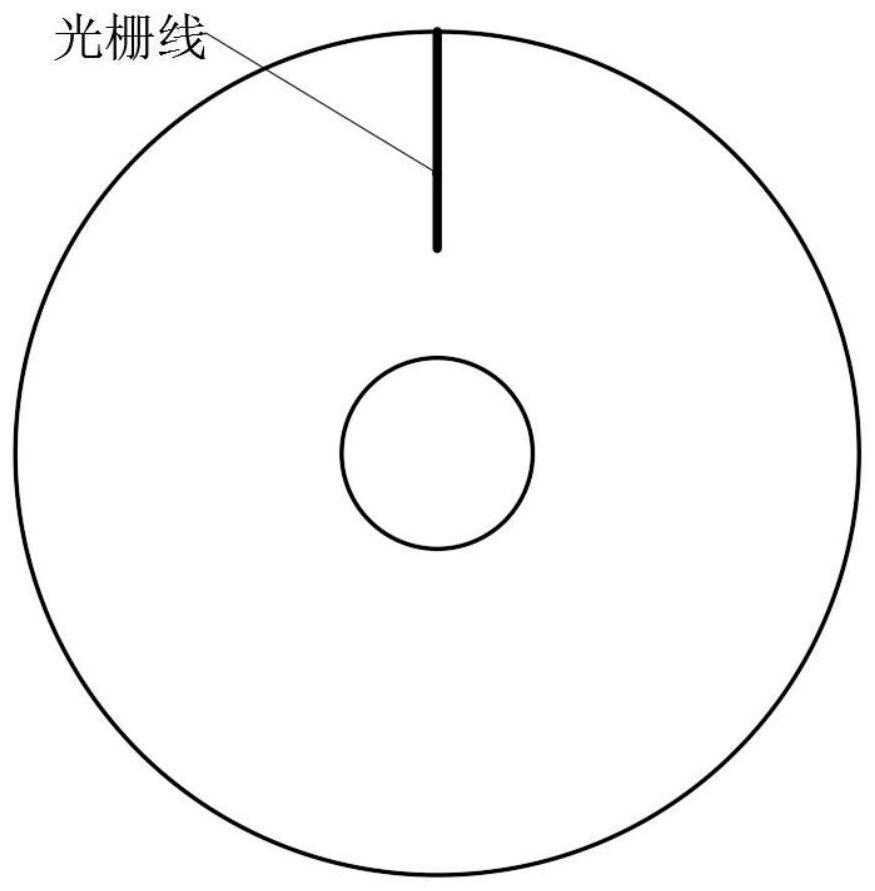

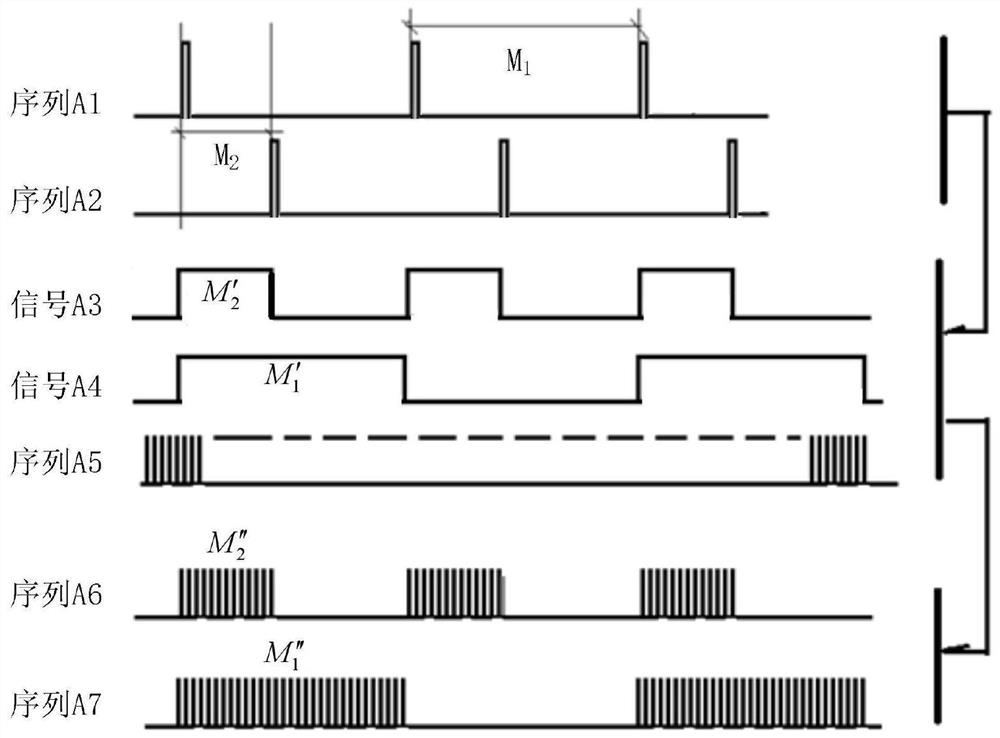

[0037] Such as figure 1 and 2 As shown, the master grating set 1 includes a first master grating plate 1-1 and a second master grating plate 1-2. The first main grating plate 1-1 and the second main grating plate 1-2 are fixed on the rotating shaft 10 at intervals. The moving grating plate 2 is fixed on the d...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the reference motor is replaced with other power components outputting constant speed rotation; the power components outputting constant speed rotation include but not limited to hydraulic motors.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that there is only one main grating sheet in the main grating group 1 . The main grating sheet is between the moving photodiode pair 3 and between the static photodiode pair 4. This embodiment has reduced a main grating sheet, but the distance from the main grating sheet to the moving grating sheet 2 and the static grating sheet 5 has been increased (a launch tube needs to be placed between the main grating sheet and the moving grating sheet 2 and the static grating sheet 5 or receiving tube).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com