Method and system for predicting sintered SmCo magnetic performance based on neural network

A technology of neural network and prediction method, which is applied in the field of prediction of sintered SmCo magnetic properties based on neural network, can solve the problem that the neural network model of sintered SmCo permanent magnet has not been reported yet, does not consider the joint influence of composition and process, and is difficult to optimize the process of specific composition Conditions and other issues to achieve the effect of improving generalization ability, better reflecting experimental conditions, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the content and advantages of the present invention, the present invention will be further described below.

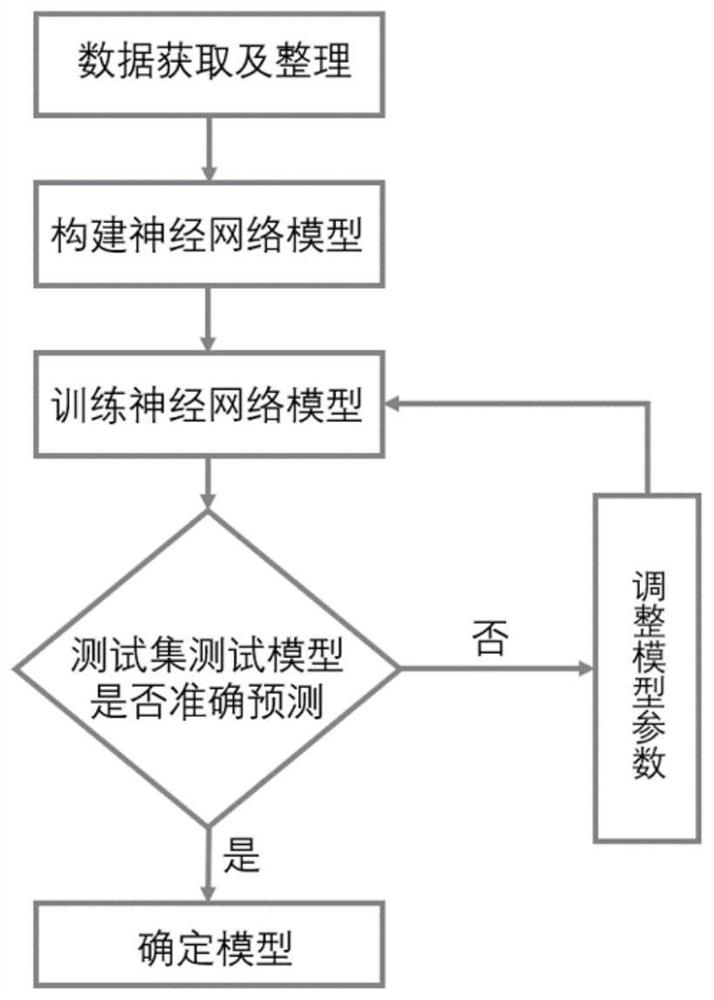

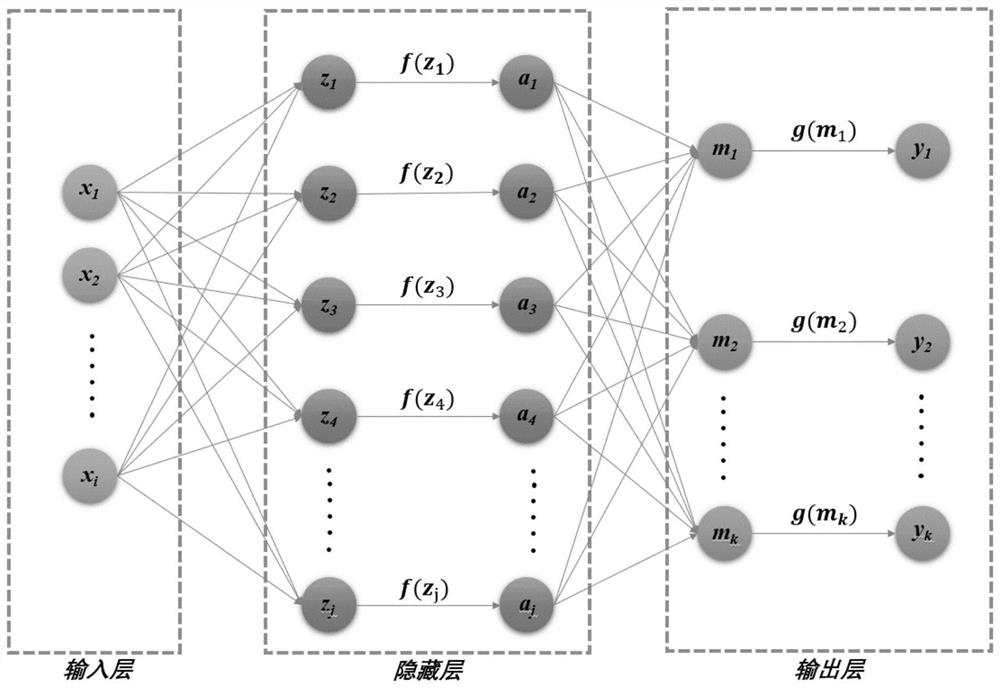

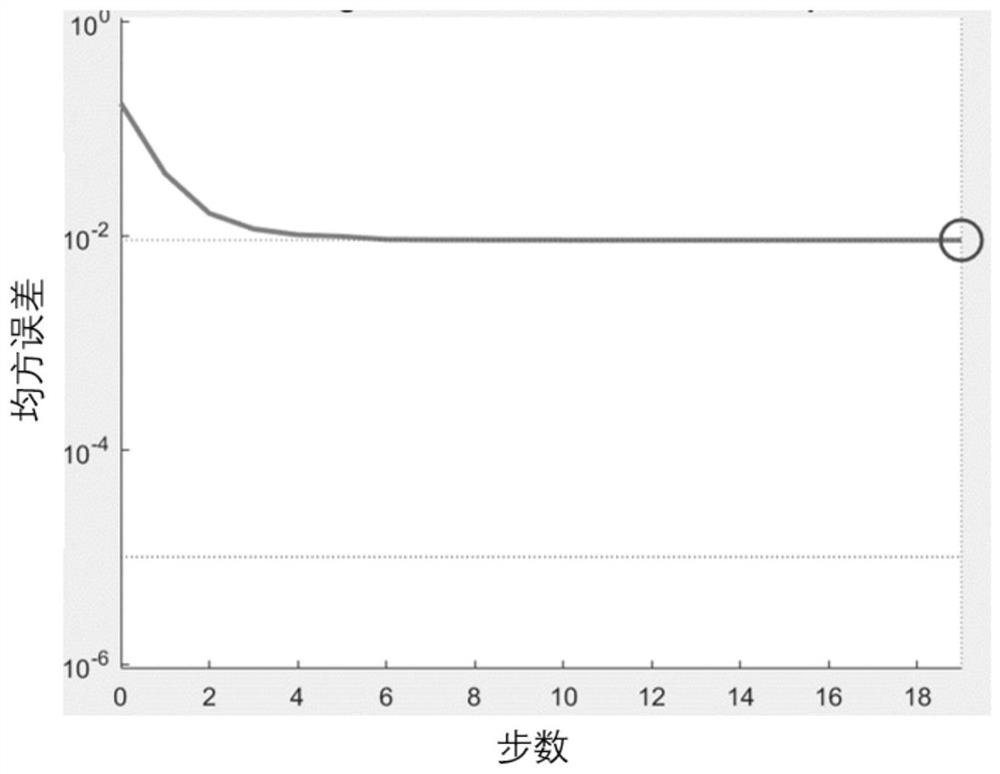

[0038] This embodiment provides a method for predicting the magnetic properties of sintered SmCo permanent magnets, including three steps:

[0039] Step 1: Sample Acquisition

[0040] Step 1.1: Study the influence mechanism of characteristic parameters on coercivity and remanence.

[0041] Sintered SmCo permanent magnets contain a variety of elements, and various elements have different effects on the magnetic properties of the magnet.

[0042]The microstructure of the sintered SmCo permanent magnet is mainly a cellular structure, in which the cell wall phase is a 1:5 phase rich in Sm and Cu, and the intracellular phase is a 2:17 phase. Among them, the coercive force of the magnet is mainly provided by the cell wall phase, and the remanence is mainly provided by the intracellular phase. Increasing the content of Sm element will l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com