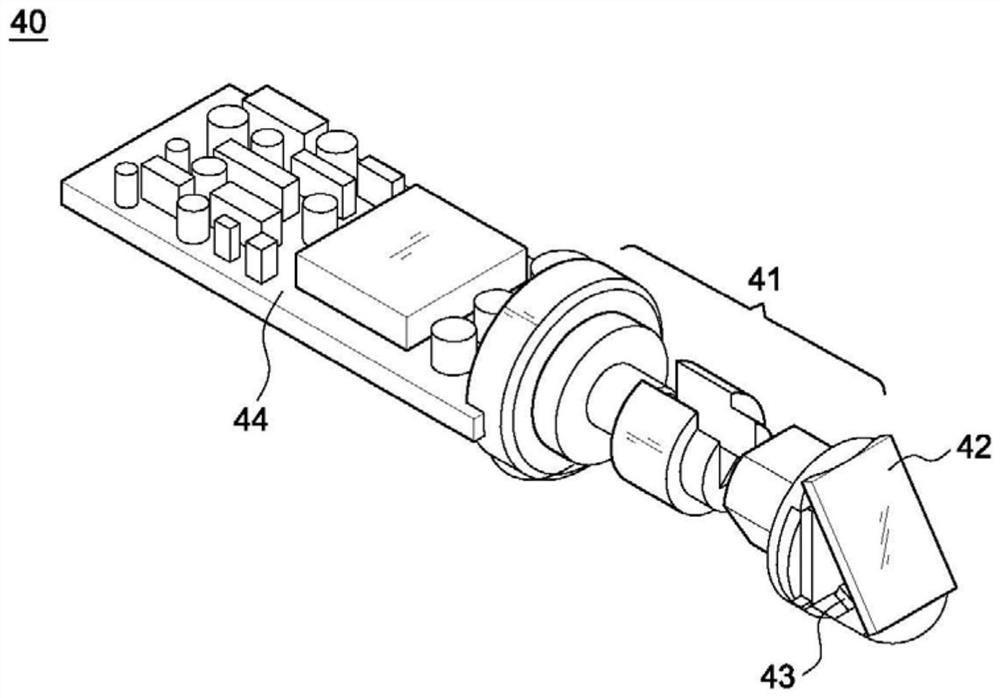

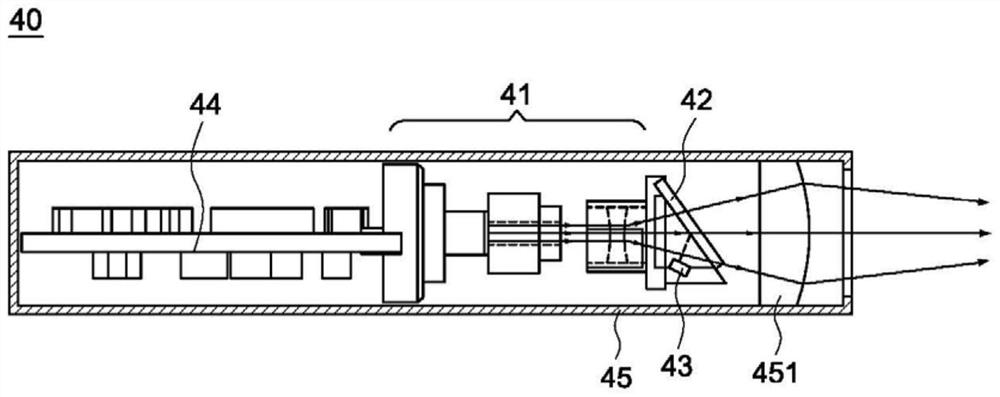

Electrically pumped photonic crystal surface-emitting laser element with light detection structure

A technology of photonic crystals and laser components, applied in electrical components, laser components, semiconductor lasers, etc., can solve the problem of time-consuming adjustments, the inability to integrate surface-emitting lasers and automatic power control laser modules, and the inability to automatically control laser power Proportion and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

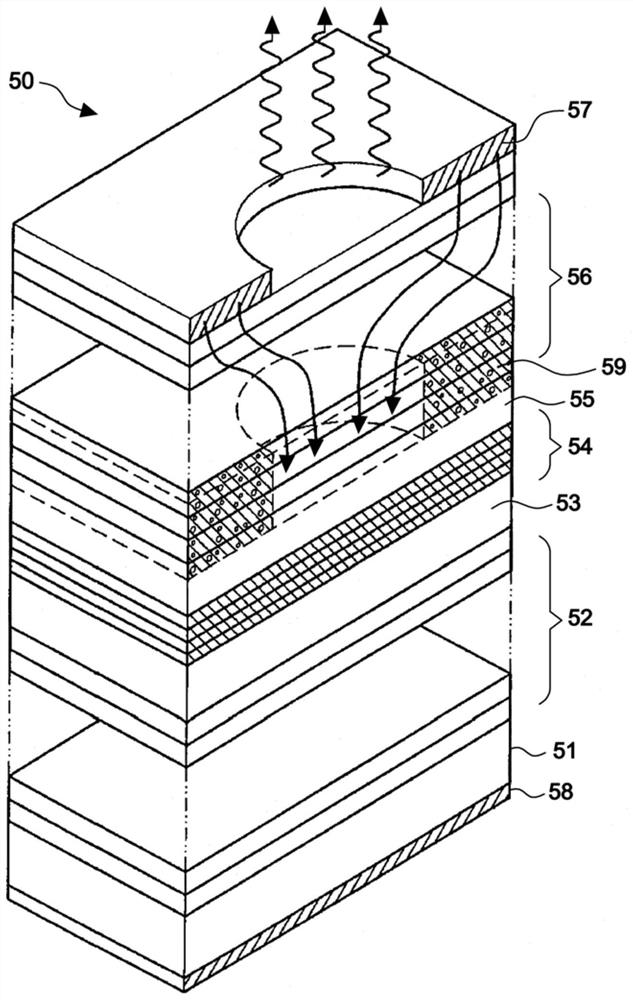

Embodiment Construction

[0049] First, see Figure 3A ~ Figure 3M As shown, the present invention provides a preferred embodiment of an electrically excited photonic crystal surface-emitting laser element (Electrically Pumped Photonic-Crystal Surface-Emitting Lasers) 10A with a photodetection structure, which extends the applicant's use of electrically excited photonic crystal surface Application number 16 / 008,223 filed by the U.S. Patent and Trademark Office, and the electro-excited photonic crystal surface-emitting laser element has been notified for approval and has not yet been published and announced, including: a substrate (substrate) 11, which has A first surface 111 and a second surface 112 on the opposite side. In this embodiment, the material of the substrate 11 can be selected from any of gallium nitride (GaN), gallium arsenide (GaAs), and indium phosphide (InP) formed, but not limited to.

[0050] A cladding layer (Cladding layer) 12 is located on the first surface 111 of the substrate 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com