Power supply circuit for applying LLC to restaurant service robot, and control method

A service robot and power circuit technology, which is applied to the power circuit and control field of restaurant service robots, can solve the problems of low efficiency, difficult design of magnetic components, and inability to exert high efficiency and high gain at the same time, so as to improve work efficiency and broaden gain. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further explained;

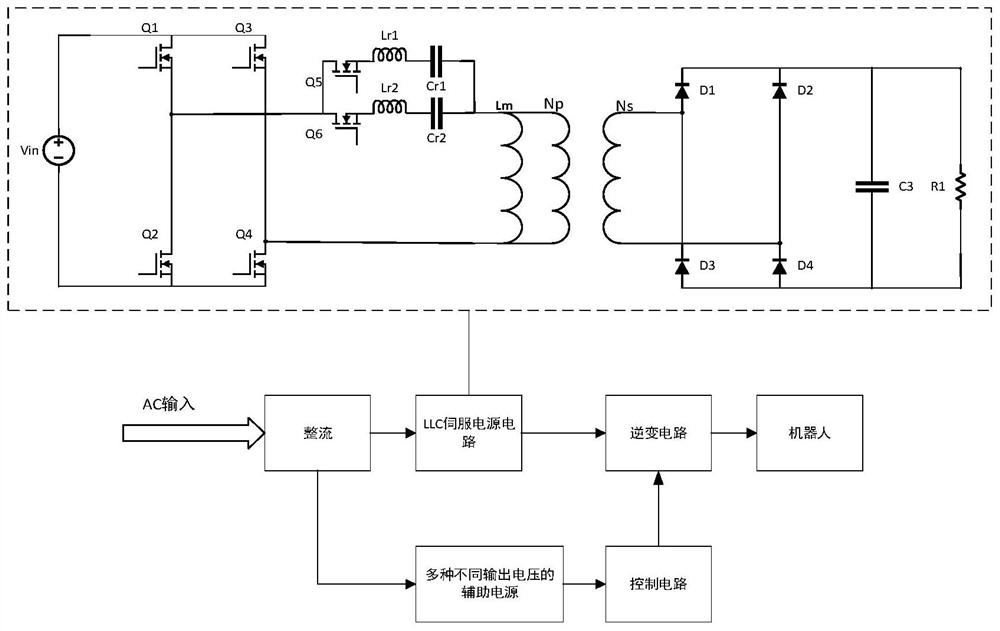

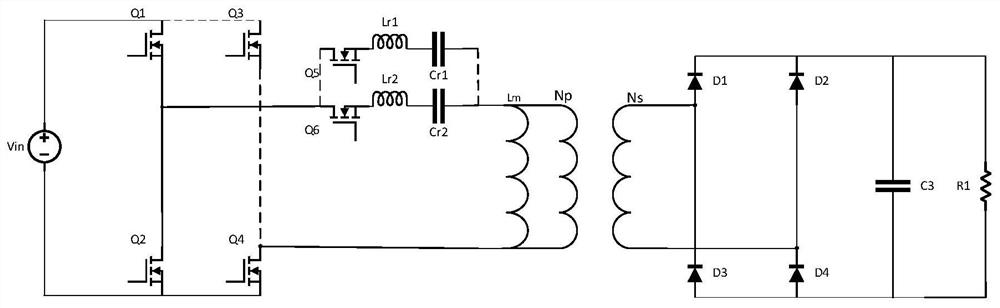

[0034] Such as figure 1 As shown, a power supply circuit using LLC for a restaurant service robot includes: a full bridge circuit, a first resonant cavity, a second resonant cavity, a transformer, a rectifier network, and fifth and sixth N-channel field effect transistors Q5 and Q6 ;

[0035] The full bridge circuit includes first, second, third, and fourth N-channel field effect transistors Q1, Q2, Q3, and Q4; the positive pole of the input voltage is connected to the drain of the first N-channel field effect transistor Q1, and the negative pole is connected to the drain of the first N-channel field effect transistor Q1. The source of the second N-channel field effect transistor Q2 is connected; the drain and source of the first N-channel field effect transistor Q1 are respectively connected to the drain of the third N-channel field effect transistor Q3 and the second N-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com