Drilling method of large-size printed board

A drilling method and technology for printed boards, which are applied in the directions of printed circuit manufacturing, printed circuits, and circuit board tool positioning, can solve the problems of printed circuit board drilling and hole deviation, achieve good alignment and reduce production costs. , Improve the effect of drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

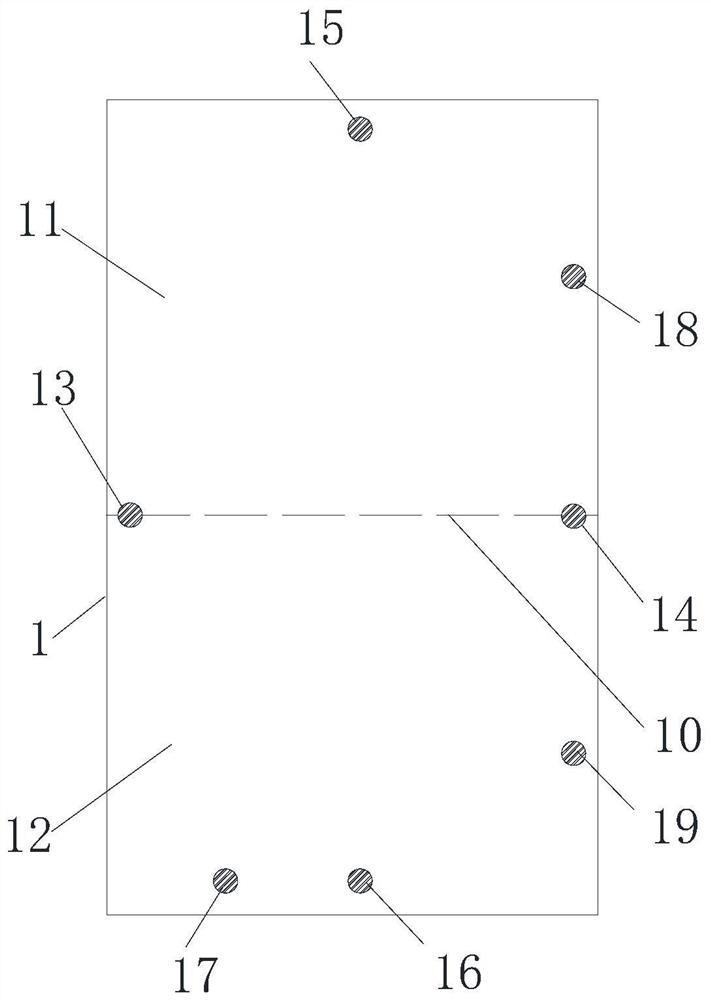

[0031] A method for manufacturing a printed board shown in this embodiment includes a drilling method for a large-sized printed board, and includes the following processing steps in turn:

[0032] (1) Cutting: cut out the core board according to the panel size 520mm×820mm, the thickness of the core board is 1mm, and the thickness of the outer copper surface of the core board is 1OZ; and the core board 1 is divided by the center line of the long side 10 Divided into first half 11 and second half 12 (such as figure 1 shown).

[0033] (2), making the inner layer circuit (negative film process): according to the pattern positioning hole, use a vertical coating machine to coat the photosensitive film on the core plate. grid exposure ruler (21 grid exposure rulers) to complete the exposure of the inner layer circuit and the inner layer target, and form the inner layer circuit pattern and target pattern after development; the inner layer etching, etch the inner layer circuit and mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com