Pre-coated aluminum material

A pre-coating, aluminum technology, used in coatings, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of reduced heat exchange efficiency, narrowed gaps between fins, increased airflow resistance, etc. Effects of excellent odor resistance, excellent press moldability, and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 9

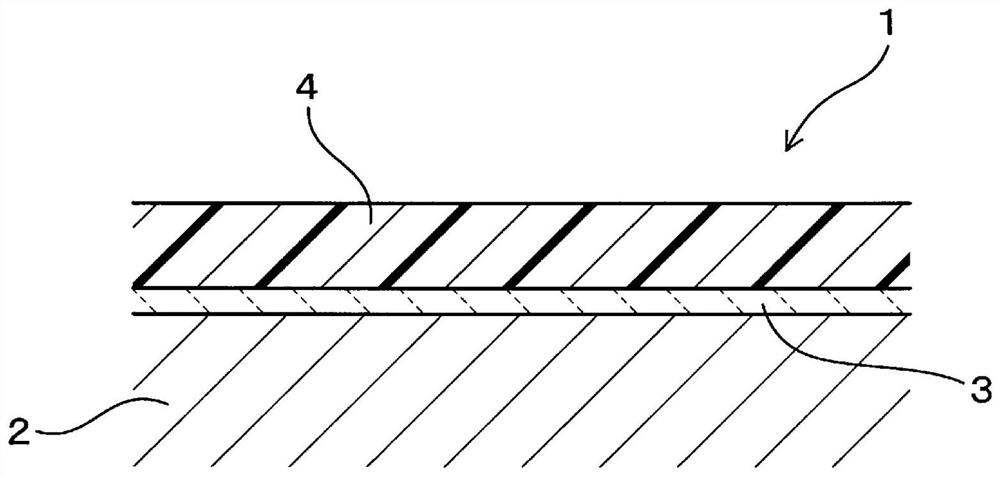

[0091] Such as figure 1 As illustrated, the precoated aluminum material 1 of the embodiment has an aluminum plate 2 , a chemical conversion film 3 , and a hydrophilic film 4 . In the precoated aluminum material 1 , an aluminum plate 2 , a chemical conversion film 3 , and a hydrophilic film 4 are laminated in this order.

[0092] Specifically, chemical conversion film 3 is formed on the surface of aluminum plate 2 , and hydrophilic film 4 is formed on the surface of chemical conversion film 3 . The chemical conversion film 3 and the hydrophilic film 4 may be formed on one side of the aluminum plate 2 or may be formed on both sides.

[0093] The chemical conversion film 3 is a phosphoric acid chromate treatment film. The hydrophilic film 4 contains an acrylic resin (A), a polyalkylene ether resin (B), a resin (C) and polyvinyl alcohol (D) as essential components.

[0094] The acrylic resin (A) is a resin that does not have a repeating unit derived from a monomer having a sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com