Application of hydroxyl-terminated polymer in preparation of multifunctional polyurethane flexible foam dressing

A hydroxyl-terminated polymer and polyurethane soft foam technology, which can be used in drug delivery, medical science, absorbent pads, etc., and can solve the problem of single function of polyurethane soft foam dressings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

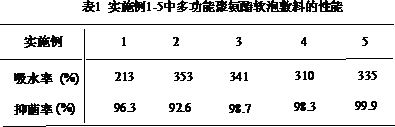

[0033] The preparation of embodiment 1 multifunctional polyurethane soft foam dressing-1

[0034] Step 1, preparation of functional foaming component (A-1)

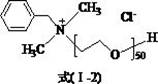

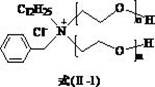

[0035] Weigh successively 12 grams of hydroxyl-terminated polyethylene glycol monomethyl ether with a mass-average molecular weight of 2000, 12 grams of single-ended hydroxyl polyvinylpyrrolidone with a mass-average molecular weight of 3800, and a formula with a mass-average molecular weight of 2200 produced by Jiangsu Haian Petrochemical Factory. Bromide N-(hydroxyl-terminated polyethylene glycol-2000)-N-dodecyl-N,N-dimethylammonium with the structure shown in (I-1) 22 grams, sodium lauryl sulfate 4 g, Add 4 g of Dow Corning 198 silicone surfactant and 8 g of purified water together into a blender, and stir at room temperature for half an hour to prepare the functional foaming component (A-1).

[0036]

[0037] Step 2, the preparation of polyurethane prepolymer (B-1)

[0038] Add 76 grams of polyethylene glycol-2000...

Embodiment 2

[0041] The preparation of embodiment 2 multifunctional polyurethane soft foam dressing-2

[0042] According to the method and operation steps of Example 1, the brominated N-(hydroxyl-terminated polyethylene glycol-2000)-N-dodecyl- N,N-dimethylammonium is replaced by N-(hydroxyl-terminated polyethylene glycol-2000)-N-benzyl-N,N-dimethylammonium chloride of the structure shown in formula (I-2), that is Prepare multifunctional polyurethane soft foam dressing-2.

[0043]

Embodiment 3

[0044] The preparation of embodiment 3 multifunctional polyurethane soft foam dressing-3

[0045] According to the method and operation steps of Example 1, the brominated N-(hydroxyl-terminated polyethylene glycol-2000)-N-dodecyl- N,N-dimethylammonium is replaced by the chloride N-(terminated hydroxyl polyethylene glycol-2000)-N-benzyl-N,N-dimethylammonium of structure shown in formula (I-2); Step The polyether diol-2000 with a mass-average molecular weight of 2000 in the second is replaced with polytetrahydrofuran diol-3000 produced by BASF Company, and the multifunctional polyurethane soft foam dressing-3 is prepared.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com