Patents

Literature

33 results about "Polyethylene glycol alkyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyl polyethylene glycol ether is a cleaning agent, or "surfactant," that can be found in a variety of household cleaning products. It works by dissolving the residue that remains on bathroom surfaces such as oils and soaps.

Antistatic masterbatch for engineering plastics and preparation method thereof

InactiveCN104844885AImprove antistatic performanceImprove mechanical propertiesPolymer sciencePolyethylene oxide

The invention discloses an antistatic masterbatch for engineering plastics and a preparation method thereof. The antistatic masterbatch for engineering plastics provided by the invention comprises the following components by mass: 15%-50% of a carrier, 25%-40% of an antistatic agent, 15%-50% of a modified calcium carbonate filler, 2%-8% of a light stabilizer, 0.5%-2% of an antioxidant, and 0.5%-5% of a dispersion agent. The antistatic agent is at least one of fatty acid polyethylene glycol ester, polyethylene glycol alkyl ether, polyethylene oxide, polyether ester amide, polyether ester imide, glycerol monostearate, alkyl sodium sulfonate, and nanoscale antimony doped tin oxide. When applied to engineering plastic production, the antistatic masterbatch provided by the invention has excellent antistatic properties, also maintains good mechanical properties and machinability, is low in production cost and convenient to use, and is suitable for a variety of engineering plastics.

Owner:王妮娜

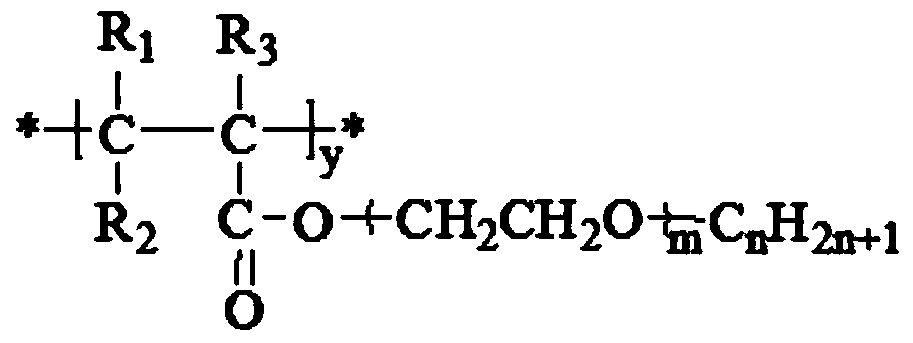

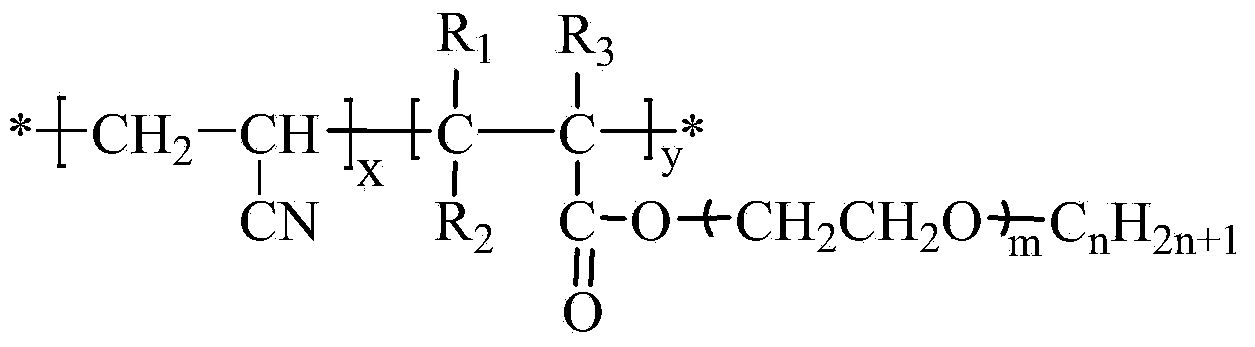

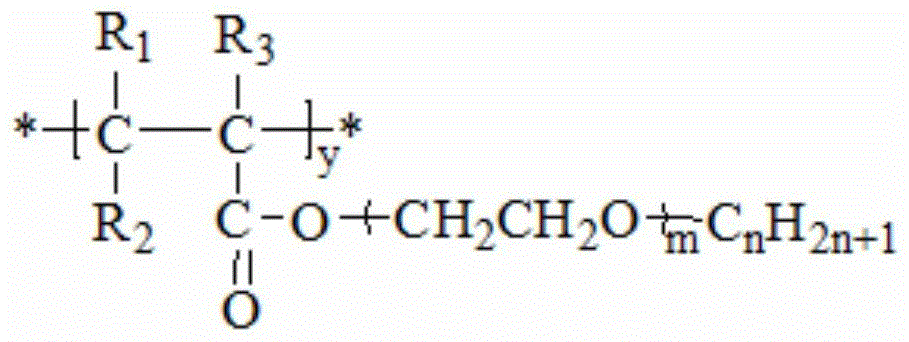

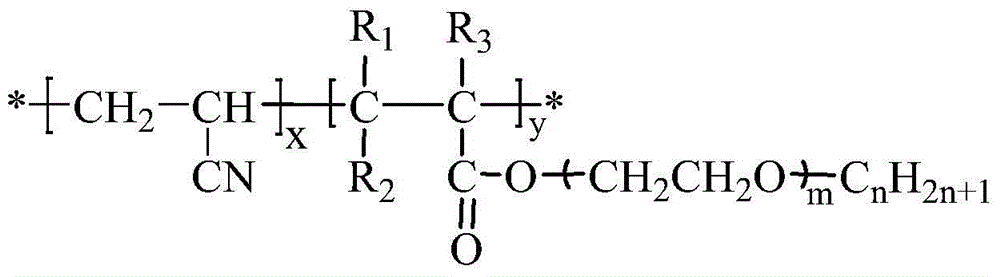

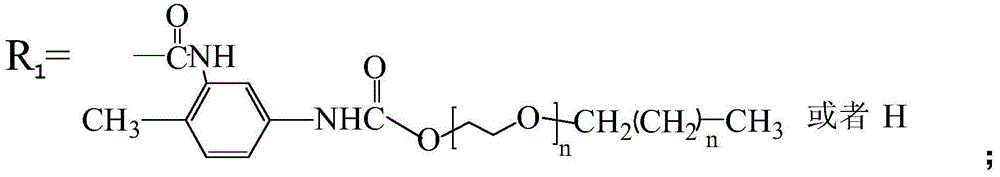

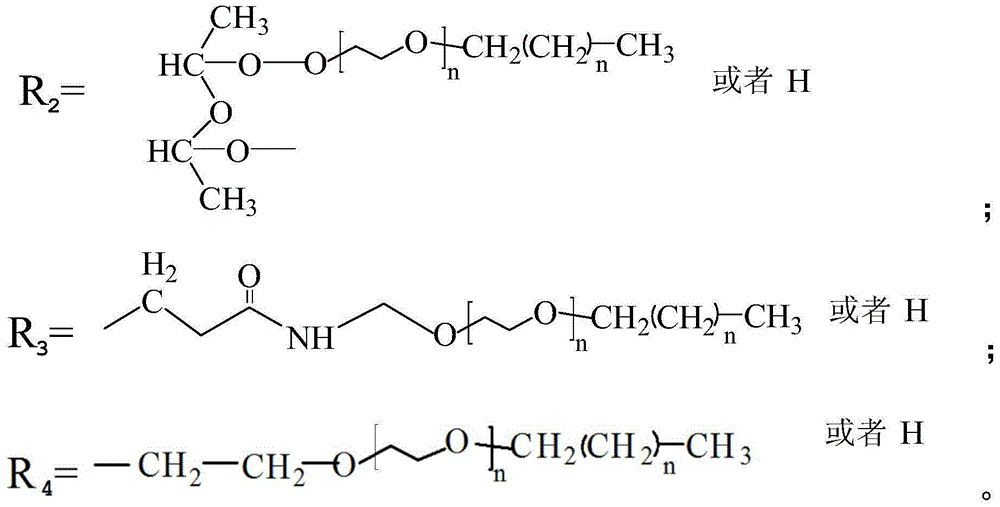

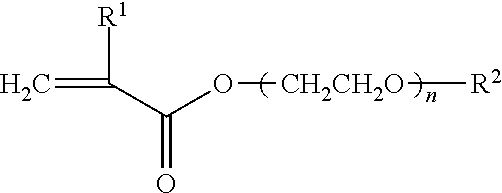

Second monomer of acrylonitrile copolymer solid-solid phase change material and preparation method and use of second monomer

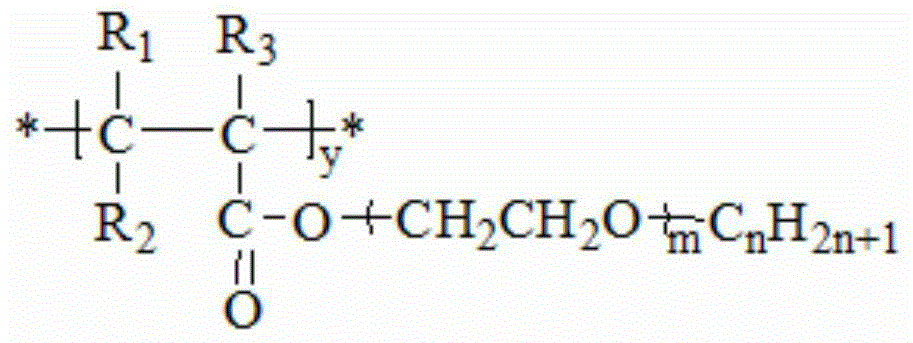

InactiveCN103980482AHas the function of heat storage and temperature adjustmentWeaken the dipole forcePreparation by ester-hydroxy reactionHeat-exchange elementsPolymer scienceDecomposition

The invention discloses a second monomer of an acrylonitrile copolymer solid-solid phase change material and a preparation method of the second monomer, a method for preparing the acrylonitrile copolymer solid-solid phase change material from the second monomer, and a method for preparing a thermo-regulated fiber / film from the prepared phase change material. The second monomer is prepared from polyoxyethylene lauryl ether reacting with ester monomers containing unsaturated double bonds in the presence of a catalyst and a polymerization inhibitor. The acrylonitrile copolymer solid-solid phase change material is prepared from the second monomer, the melting point of the material can be lower than the decomposition temperature, and the acrylonitrile copolymer solid-solid phase change material is applicable to melt spinning. The phase change material is spun and filmed under the melting condition after being mixed with a thermal stabilizer, so as to prepare the fiber / film with good energy storage and temperature adjustment performances.

Owner:TIANJIN POLYTECHNIC UNIV

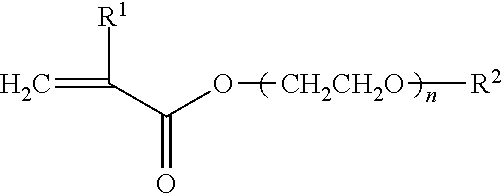

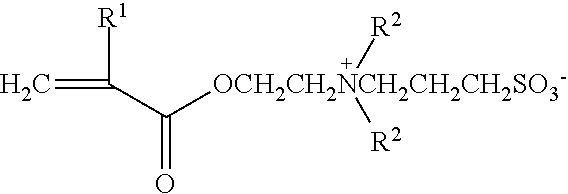

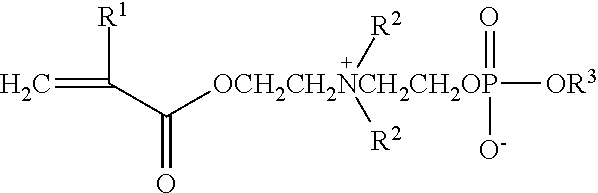

Bondable blood-friendly polymer and preparing method thereof

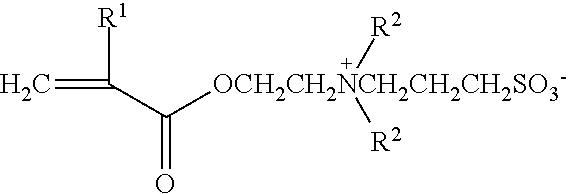

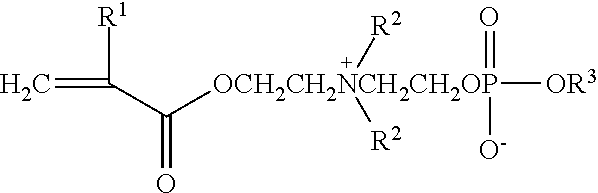

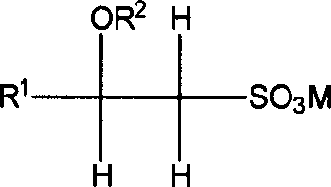

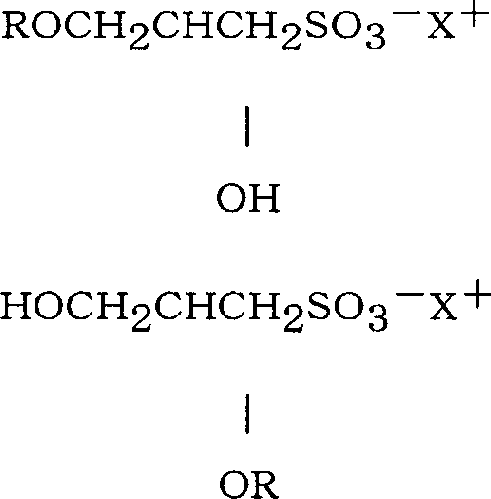

ActiveUS20160083610A1Improve propertiesReduce coatingSynthetic resin layered productsEster polymer adhesivesMethacrylateSilanes

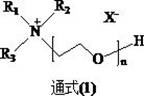

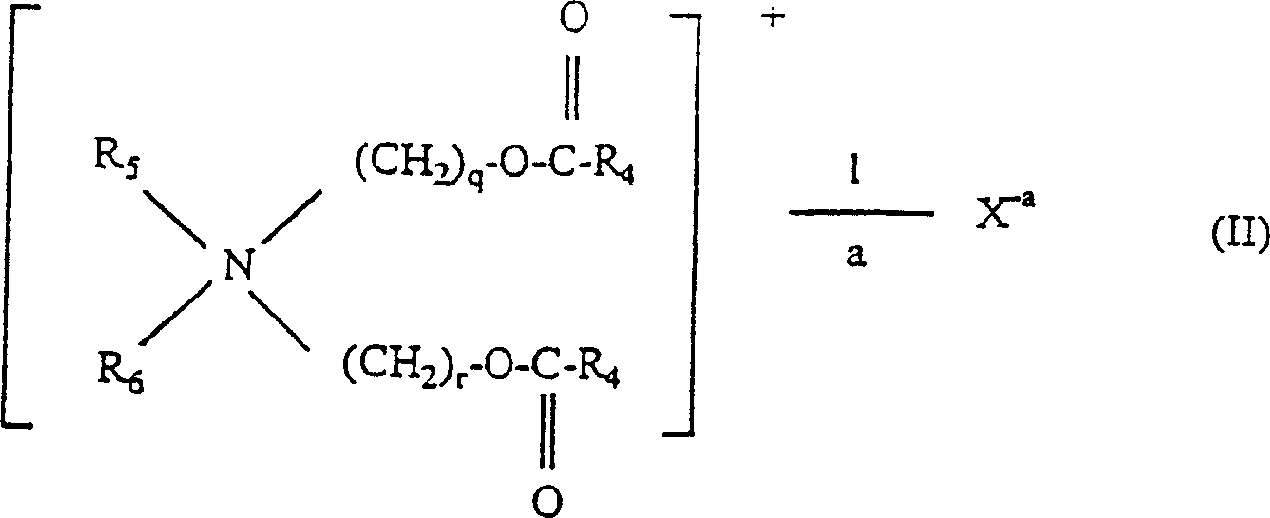

A bondable blood-friendly polymer is a terpolymer or a quadripolymer at least formed by polyethylene glycol alkyl ether acrylate or polyethylene glycol alkyl ether methacrylate (I), and zwitterionic acrylic ester or zwitterionic methacrylic ester (II), and acrylic acid or a methacrylate derivative with an epoxypropyl group, an isocyanate group, a trialkoxy silane, a hydroxyalkyl group, a propargyl group or a quaternary ammonium group (III). In the present invention, the blood-friendly polymer with a potentially-bondable group has the following advantages: although the water insolubility thereof is implemented by using the hydrophobicity physical effect of an existing higher alkyl acrylate linkage, the blood friendliness of a coating is reduced due to the existence of a great number of hydrophobic chain links in the polymer; and a physical coating is slowly desolventized from the surface to be ablated in the application process of the physical coating. A disclosed bondable blood-friendly polymer coating not only can overcome these defects, but also can improve the blending property thereof. Disclosed are composition, a structure and a preparation method of the bondable blood-friendly polymer.

Owner:ANQING GOUYOU BIOMATERIALS TECH CO LTD

Shampoo containing an alkyl ether

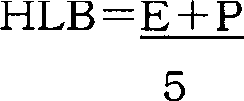

The compositions of the present invention relate to improved shampoo compositions comprising from about 5 to about 50 weight percent detersive surfactant, at least about 0.05 weight percent polyalkylene oxide alkyl ether, the The polyalkylene oxide alkyl ether is selected from the group consisting of polyethylene glycol alkyl ether, polypropylene glycol alkyl ether, polyethylene glycol polypropylene glycol alkyl ether, and combinations thereof, and the shampoo composition also contains at least about 20.0 wt. % of aqueous carrier; wherein the HLB value of the polyalkylene oxide alkyl ether is less than 10.

Owner:THE PROCTER & GAMBLE COMPANY

Polyvinyl chloride material with good antibiosis and anti-ultraviolet properties

InactiveCN104861376AGood antibacterial and UV protection effectFunction increaseMethacrylateUltraviolet

The invention discloses a polyvinyl chloride material with good antibiosis and anti-ultraviolet properties. The polyvinyl chloride material comprises, by mass, 55-75% of polyvinyl chloride, 5-10% of di(2-ethylhexyl)phthalate, 6-12% of nanometer attapulgite, 5-8% of ethylene-octylene copolymer, 3-7% of methacrylate-acrylate copolymer, 1-3% of polyethylene glycol alkyl ether, 1-2% of an ultraviolet ray absorber, 0.5-1.5% of a calcium and zinc composite stabilizer, 0.5-1% of calcium stearate, 0.1-0.5% of nanometer silver and 0.1-0.5% of an antioxidant 1010. The polyvinyl chloride material has excellent antibiosis and anti-ultraviolet effects, has an antibiosis rate reaching above 98%, and also has the advantages of good heat stability, high impact strength, wide adaptation range, low cost, and easy popularization and application.

Owner:殷培花

Aqueous liquid crystal display cleaning agent compounds and their fabrication methods

InactiveUS20070149433A1Low toxicityEasy to cleanCationic surface-active compoundsNon-ionic surface-active compoundsAdditive ingredientCleansing Agents

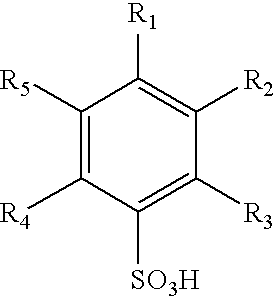

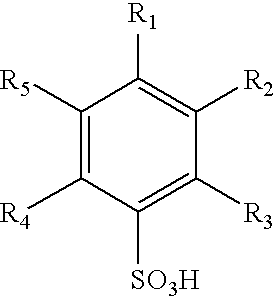

The present invention discloses aqueous LCD cleaning agent compounds and their fabrication methods. Said cleaning agent compounds comprise of polyoxyethylene glycol bistearate, polyoxyethylene fatty alcohol ether, polyethylene(3) glycol alkyl ether tri(alkyl ethers)amine sulfate and / or polyethylene(3) glycol enyl ether tri(alkyl ethers)amine sulfate, alkyl benzenesulfonic acid, lecithins and water. In particular, the weight of the ingredients in the compounds as a weight percentage of the weight of the compounds is: polyoxyethylene glycol bistearate (10-50 wt %), polyoxyethylene fatty alcohol ether (5-60 wt %), polyethylene(3) glycol alkyl ether tri(alkyl ethers)amine sulfate and / or polyethylene(3) glycol enyl ether tri(alkyl ethers)amine sulfate (5-20 wt %), alkyl benzenesulfonic acid (1-15 wt %), lecithins (1-10 wt %), water (5-50 wt %). Embodiments of the aqueous LCD cleaning agent compounds of the present invention can effectively remove both the crystal liquid materials in the gaps between the two glass substrates and foreign contaminate particles attached on the surfaces of the glass substrates. Moreover, the LCD cleaning agent compounds have the characteristics of low toxicity, environmental friendliness, low flammability and high cleaning capabilities for various crystal liquid materials.

Owner:BYD CO LTD

Application of polyurethane-based interpenetrating network polymer in surface modification of medical catheter

The invention provides an application of a polyurethane-based interpenetrating network polymer in surface modification of a medical catheter. The application comprises the following steps: respectively carrying out addition reaction on hydrophilic substances including hydroxyl-terminated polyethylene glycol alkyl ether, single hydroxyl-terminated polyvinylpyrrolidone and hydroxyl-terminated polyether quaternary ammonium salt and a polyisocyanate tripolymer to prepare a functional polyurethane prepolymer; and blending the functional polyurethane prepolymer with quaternary ammonium cationized dihydric alcohol with antibacterial and bactericidal functions, and carrying out step-by-step addition polymerization reaction to obtain the polyurethane-based interpenetrating network polymer which isused for surface hydrophilic antibacterial modification of medical catheters.

Owner:JIANGSU OCEAN UNIV

Antistatic and aging resistant PET/PTT alloy and preparation method thereof

InactiveCN104845259AImprove antistatic performanceImprove aging resistancePolyethylene oxideAntioxidant

The invention discloses an antistatic and aging resistant PET / PTT alloy and a preparation method thereof. The antistatic and aging resistant PET / PTT alloy comprises the following components by mass: 34%-60% of PET, 20%-40% of PTT, 3%-5% of SMA, 1%-3% of nano-silicon dioxide, 8%-12% of glass fiber, 1%-3% of an antistatic agent, 0.5%-2% of an aging resistant agent, 0.1%-0.5% of an antioxidant, and 0.1%-1% of TAF. The antistatic agent is one of polyethylene oxide, polyether ester amide, polyether ester imide, polyethylene glycol alkyl ether, glycerol monostearate, and alkyl sodium sulfonate. The antistatic and aging resistant PET / PTT alloy provided by the invention has the respective advantages of PET and PTT, also has the characteristics of excellent antistatic performance and aging resistance, high strength, good machinability and low cost, and is suitable for industrial production and popularization and application.

Owner:王妮娜

PC/PTT alloy material of enhanced antistatic property

InactiveCN104845335AImprove antistatic performanceHigh mechanical strengthPolyethylene oxideAntioxidant

The present invention discloses a PC / PTT alloy material of enhanced antistatic property, which comprises the following components in mass percentage: 40% to 60% of PC, 20% to 30% of PTT, 2% to 4% of E-MA-GMA, 8% to 15% of glass fibers, 5% to 8% of ACR, 1% to 3% of antistatic agent, 0.5% to 2% of light stabilizer, 0.1% to 0.5% of antioxidant, and 0.1% to 1% of lubricant. The antistatic agent is at least one selected from fatty acid polyglycol ester, polyoxyethylene lauryl ether, polyethylene oxide, polyether ester amide, polyether urethane imide, glycerol monostearate, alkyl sodium sulfonate, and nano-scale antimony-doped tin oxide. According to the invention, the original advantages of PC and PTT are integrated, and the PC / PTT alloy material is excellent in anti-static property. The surface resistance of the PC / PTT alloy material is up to 108 to 10 omega. Meanwhile, the PC / PTT alloy material is high in mechanical strength, good in impact toughness, excellent in chemical resistance, low in cost and wide in adaptability.

Owner:QINGDAO JIAYIYANG IND & TRADE

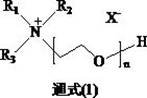

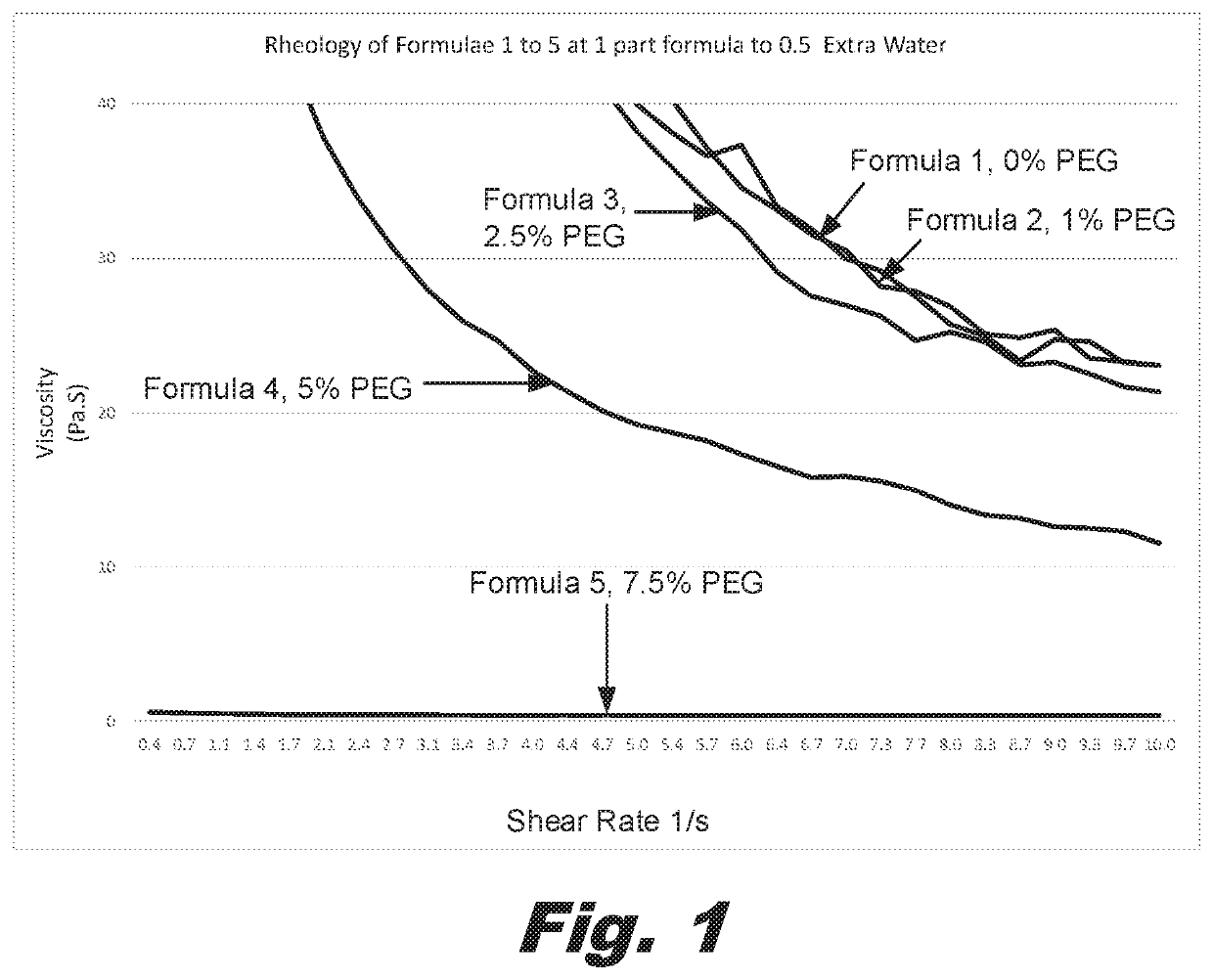

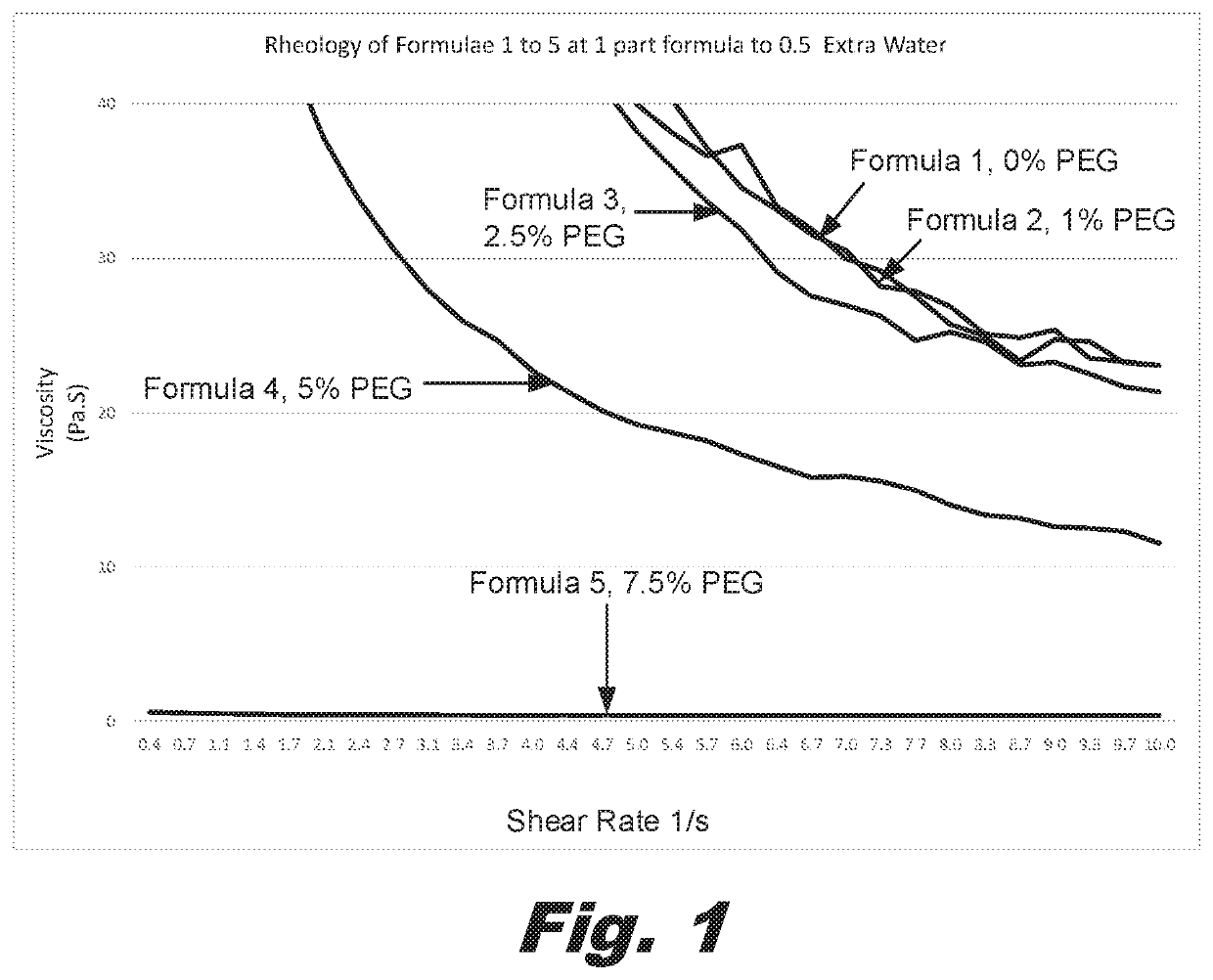

Use of polyglycols to control rheology of unit dose detergent compositions

ActiveUS11046915B2Organic detergent compounding agentsNon-ionic surface-active compoundsSulfonateLinear alkylbenzene sulfonate

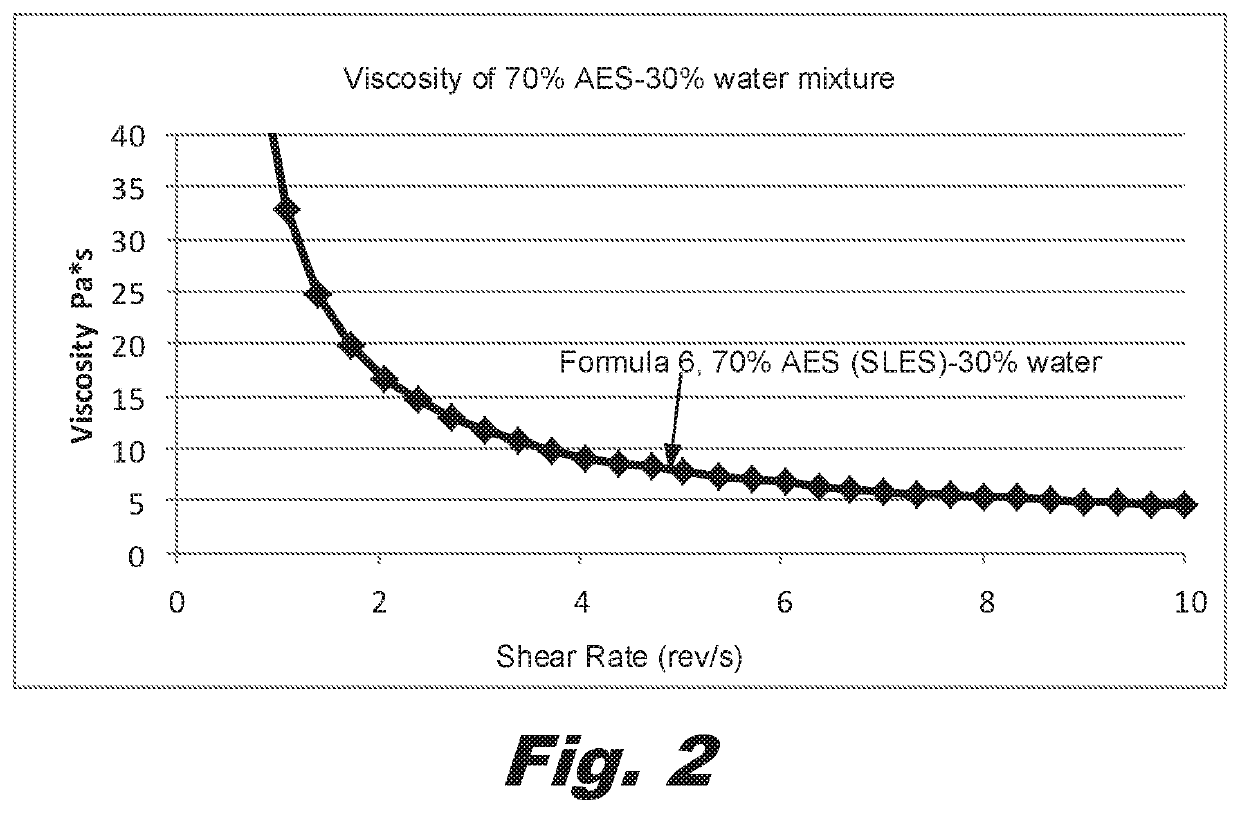

A method for maintaining a consistent, low viscosity profile of a unit dose detergent composition for enhanced hydration and dissolution upon hydration including the steps of: (1) A method for maintaining a consistent, low viscosity profile of a unit dose detergent composition for enhanced hydration and dissolution upon hydration including the steps of: (1) providing the detergent composition including: about 2.5 to about 15 wt. % of a polyglycol, an alkyl-ether sulfate, a linear alkylbenzene sulfonate, and a fatty alcohol ethoxylate, wherein the alkyl-ether sulfate, linear alkylbenzene sulfonate, and fatty alcohol ethoxylate are collectively present in an amount of 30 to 70 wt. %, by weight of the detergent composition; and (2) encapsulating the detergent composition in a pouch made of a water soluble film.

Owner:HENKEL KGAA

Super concentrated liquid rinse cycle fabric softening composition

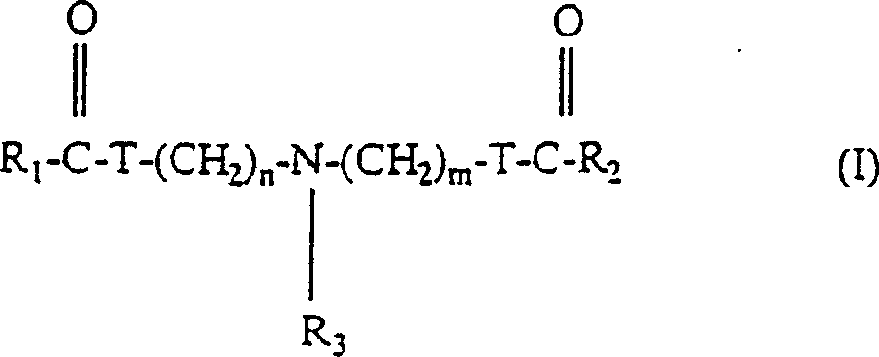

InactiveCN1252833AGood dispersionCationic surface-active compoundsOrganic detergent compounding agentsFatty alcoholSURFACTANT BLEND

Super-concentrated liquid rinse cycle fabric softeners are provided which contain more than 35 %, by weight, of a fabric softening system based on an amidoamine fabric softener, such as bis(tallow amidoethyl)-2-hydroxyethyl amine and a quaternary diester fabric softener, such as N-methyl, N,N,N-triethanolamine ditallow ester quaternary ammonium salt. A fatty alcohol ethoxylate surfactant and a polyethylene glycol polymer or a polyethylene glycol alkyl ether polymer are integral components of the liquid composition. The super-concentrated compositions may be used at low levels or may be further diluted prior to use.

Owner:COLGATE PALMOLIVE CO

Preparation method and application of second monomer for acrylonitrile-based copolymer solid-solid phase change material

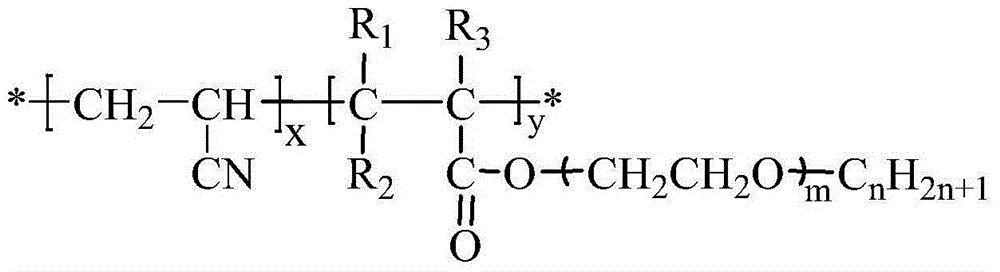

ActiveCN103965464AGood energy storageGood heat release functionPreparation from carboxylic acid halidesHeat-exchange elementsDecompositionAcrylonitrile

The invention discloses a preparation method of a second monomer for an acrylonitrile-based copolymer solid-solid phase change material, a method for preparing the acrylonitrile-based copolymer solid-solid phase change material from the second monomer, and a method for preparing an energy-storage and temperature-adjustment fiber / film from the phase change material prepared from the second monomer. The second monomer is prepared by the steps of enabling polyoxyethylene alkyl ether to react with sodium in methylbenzene, then enabling the reactant to react with an allyl monomer containing acyl chloride groups to obtain a crude product, and washing and carrying out liquid separation on the crude product. The acrylonitrile-based copolymer solid-solid phase change material prepared from the second monomer has the melting point being lower than the decomposition temperature and is applicable to melt spinning. The fiber / film with favorable energy-storage and temperature-adjustment performances can be prepared by mixing the acrylonitrile-based copolymer solid-solid phase change material with a thermal stabilizer and then spinning and filming under molten conditions.

Owner:TIANJIN POLYTECHNIC UNIV

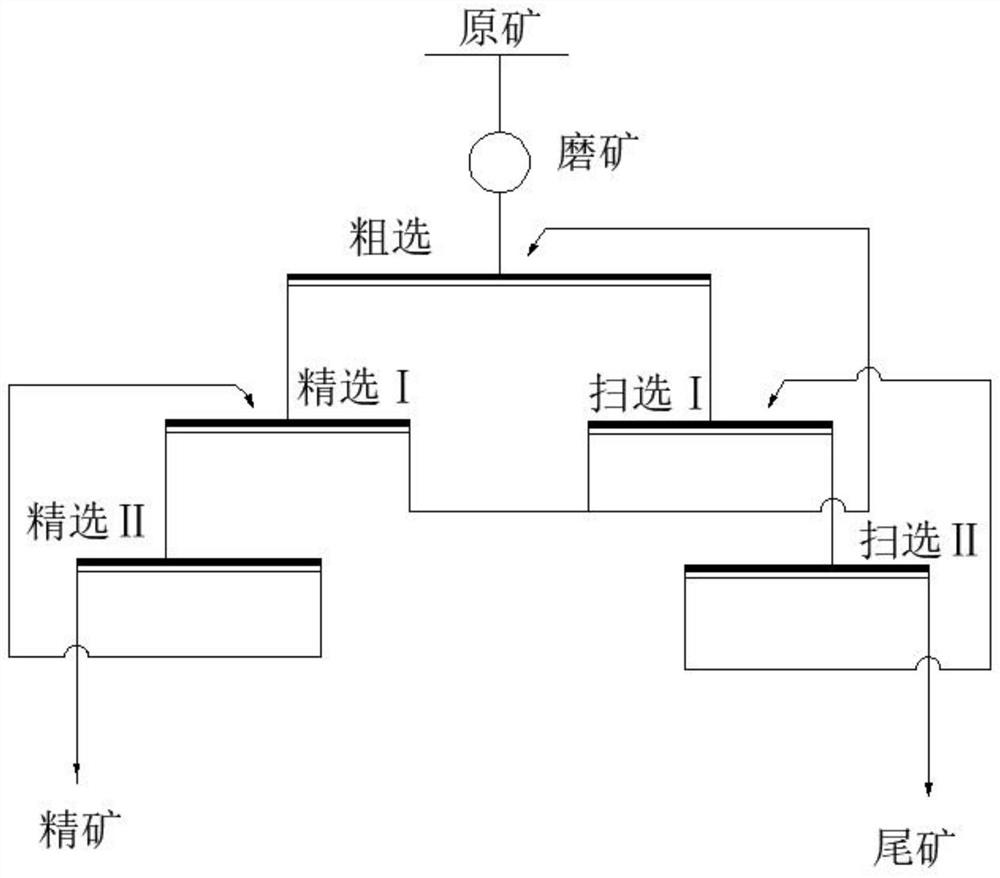

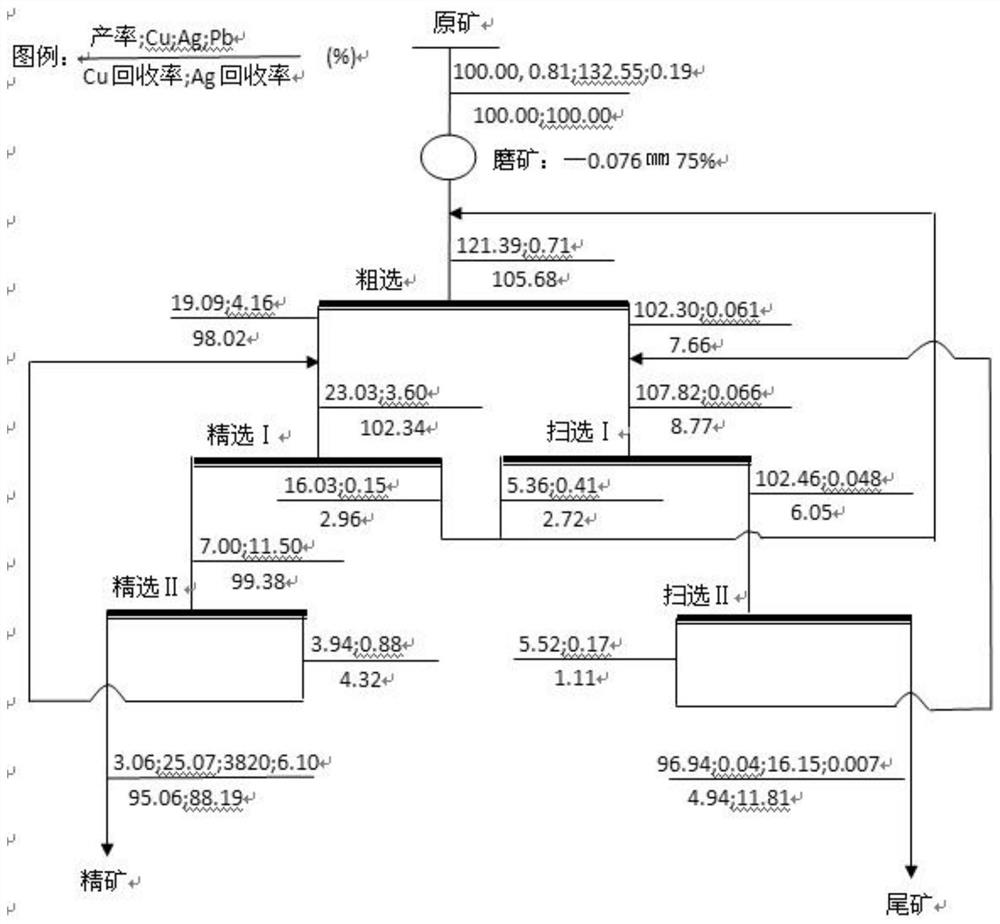

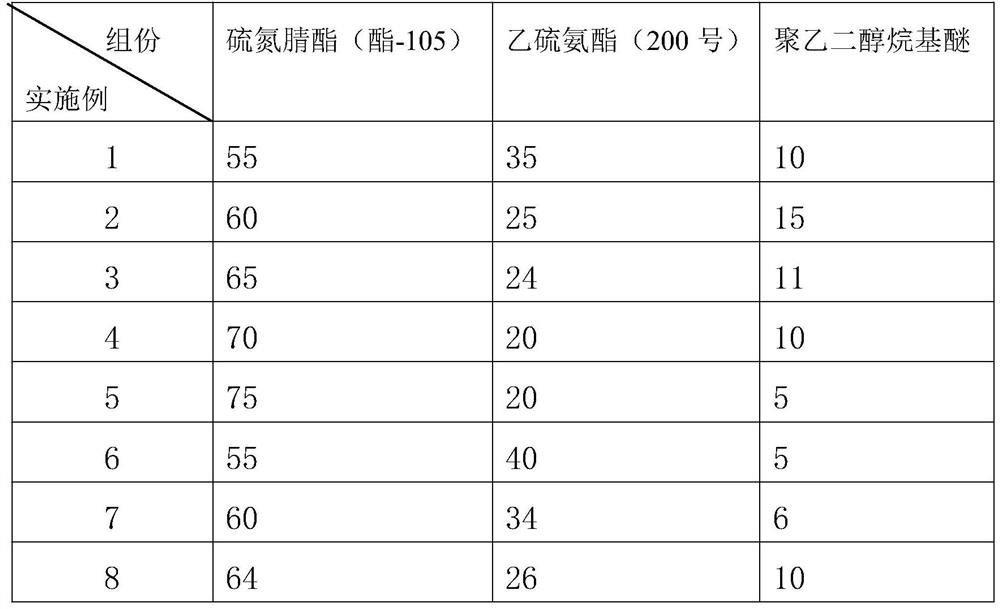

Collecting agent for flotation of complex and difficult-to-treat copper-silver sulfide ore

PendingCN114210462ANo pollutionSolve the technical problems of beneficiation that are difficult to use efficientlyFlotationFoaming agentCopper sulfide

The invention discloses a collecting agent for flotation of complex and difficult-to-treat copper sulfide silver ore, which is prepared by mixing the following components in percentage by mass: 55 to 75 percent of sulfur nitrogen nitrile ester, 20 to 40 percent of ethionine ester and 5 to 15 percent of polyethylene glycol alkyl ether. The collecting agent disclosed by the invention not only has very strong collecting performance, but also has foamability, so that the cost of a foaming agent can be saved in production; due to the fact that the collecting agent MT-23 is high in capacity, the total consumption of the agent per ton of ore is extremely low; the flotation cost is saved by more than 25% compared with that of an existing agent; the collecting agent is non-toxic, odorless and easy to degrade, belongs to a green and environment-friendly mineral separation collecting agent, and has a wide popularization prospect. By the adoption of the method, the recovery rate of copper and silver can be remarkably increased on the premise that the quality of copper-silver concentrate products is guaranteed, and the method has the advantages of being simple in technological process, stable, reliable, high in applicability, simple in reagent system, small in reagent dosage, convenient to add and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

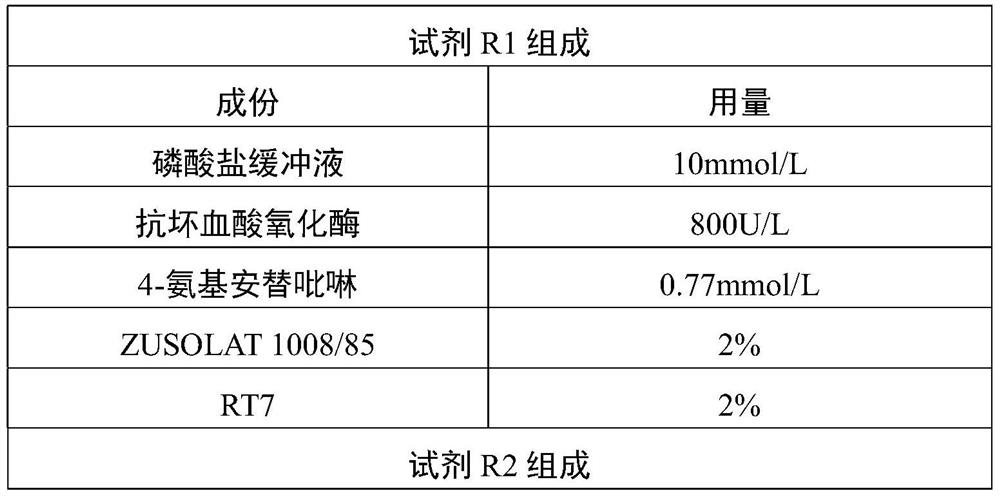

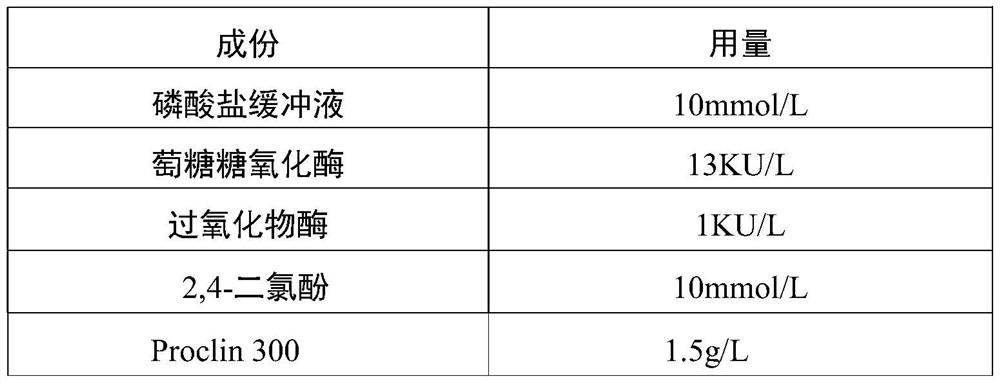

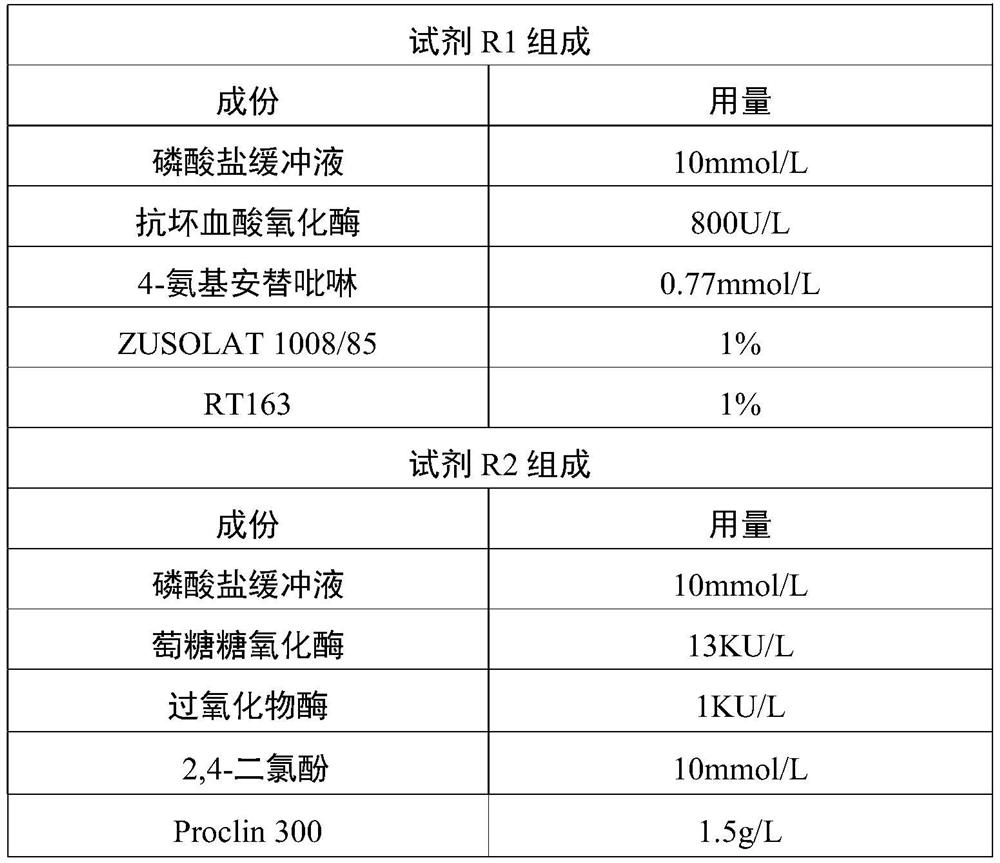

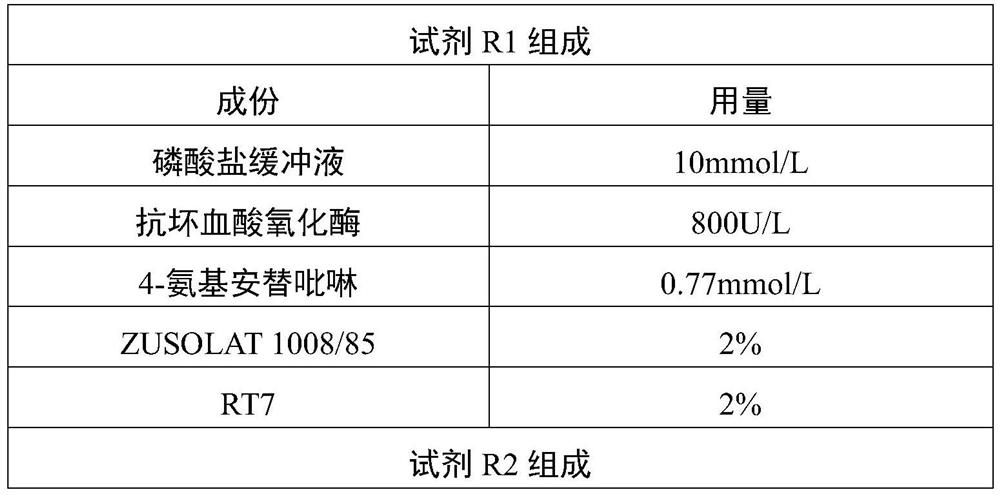

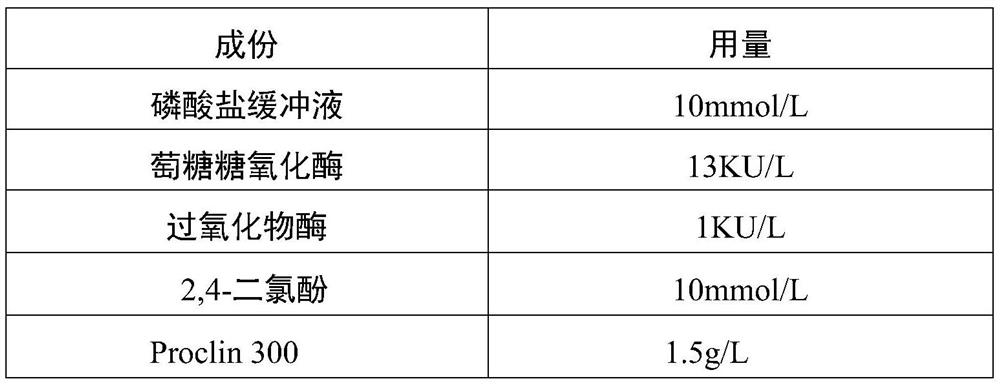

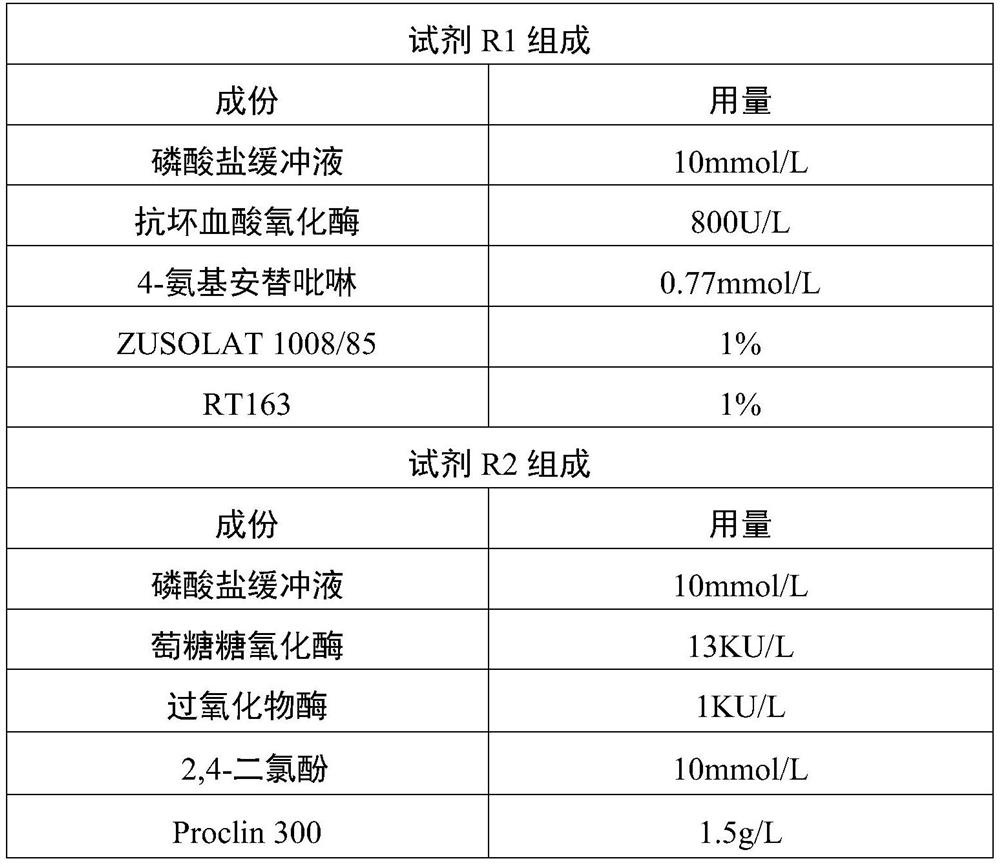

Kit for determining glucose content and application thereof

ActiveCN112710656AEliminate distractionsImprove accuracyMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPolyethylene oxideActive agent

The invention relates to the technical field of in-vitro detection, in particular to a kit for determining glucose content and application thereof. The kit comprises an anti-chyle interference reagent, and the anti-chyle interference reagent is selected from one or more of a polyethylene oxide fatty alcohol nonionic surfactant, a polyethylene oxide-propylene oxide fatty alcohol nonionic surfactant, a polyethylene glycol alkyl ether nonionic surfactant and a mixed fatty glyceride nonionic surfactant. On the basis of basic components of the glucose determination kit, 0.01%-10% of one or more specific surfactants are added into a detection reagent, so that the interference of chyle in a lipid blood sample on glucose determination is eliminated, and the accuracy of glucose detection in the lipid blood sample is improved; the reagent is simple in component and easy to produce and prepare; and the cost is low, and commercialization is easy.

Owner:BIOSINO BIO TECH & SCI

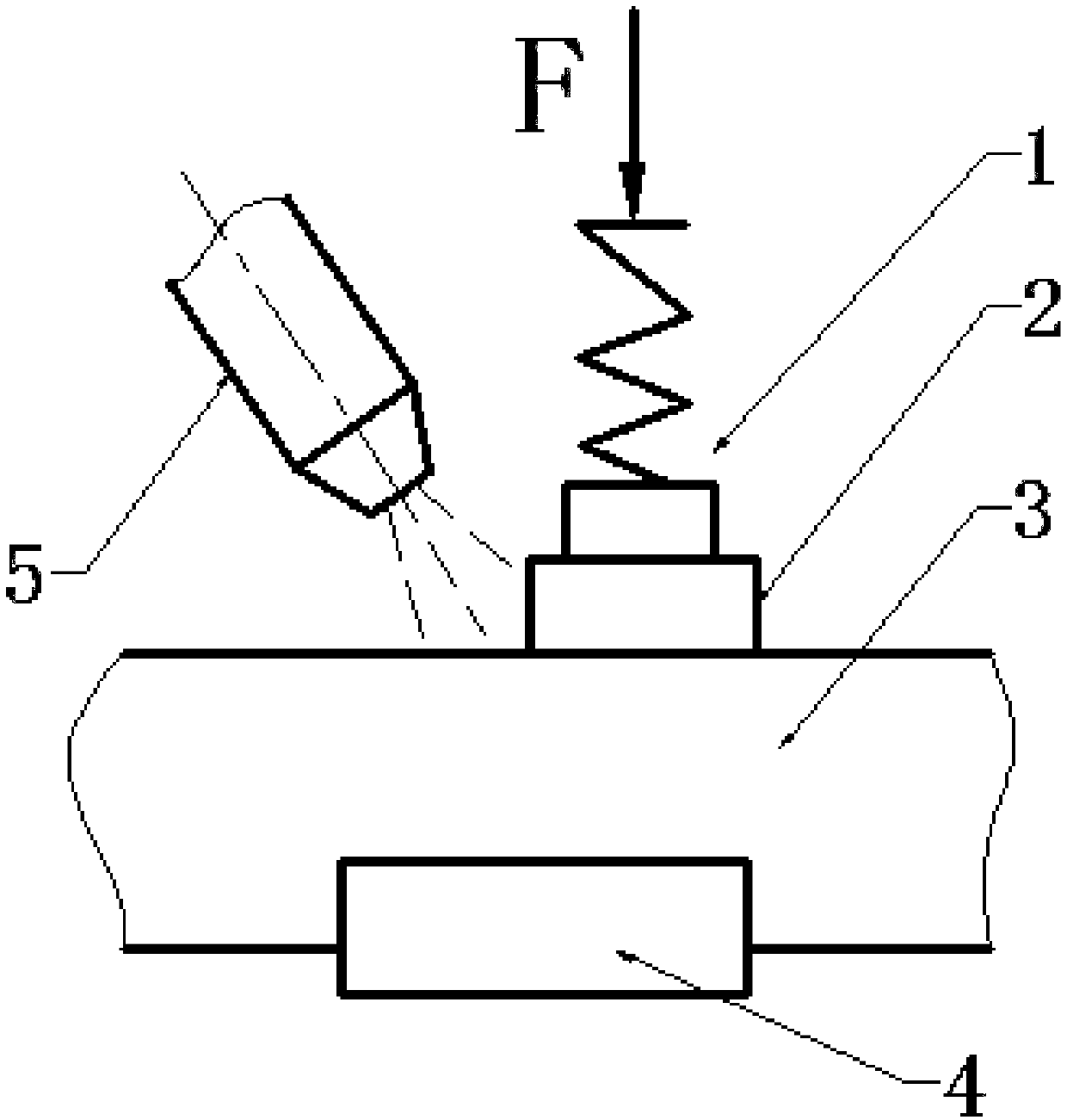

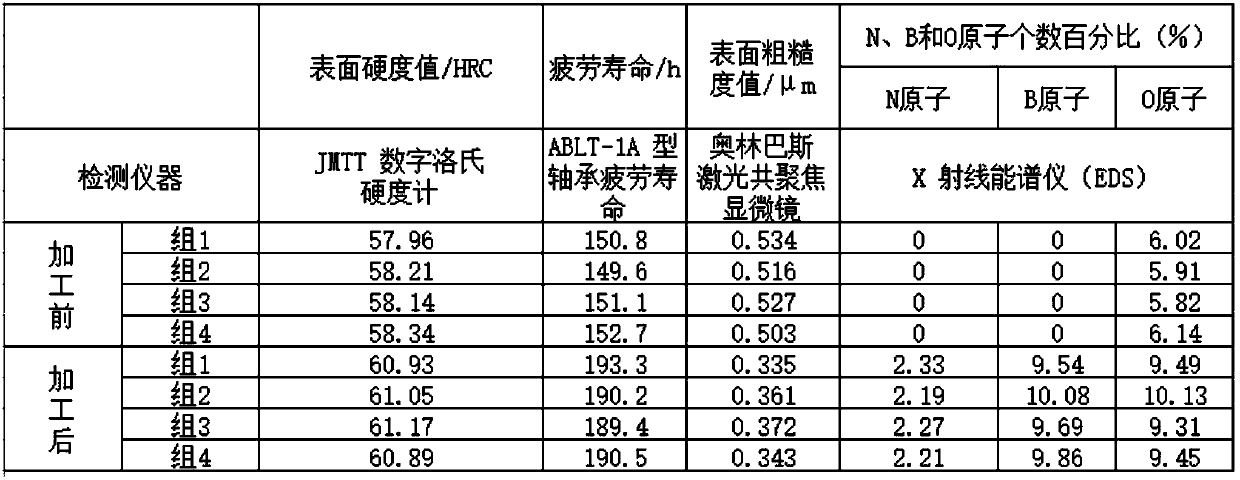

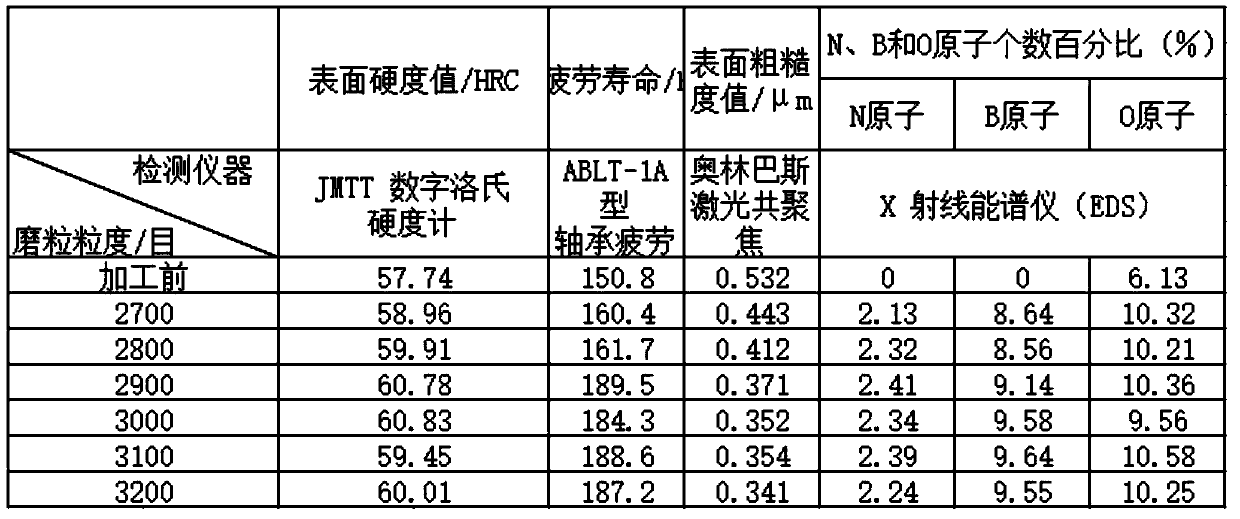

Nitrogen-rich water-based enhanced superfinishing method for alloy workpiece surface and formula of superfinishing liquid

InactiveCN109554659AImprove surface strengthSufficient cooling and lubricationSolid state diffusion coatingSuperfinishing machinesEthylenediamineWater based

The invention discloses a nitrogen-rich water-based enhanced superfinishing method for the alloy workpiece surface and a formula of superfinishing liquid. The superfinishing liquid is prepared from anitrogen-rich water-based superfinishing concentrated solution and water, wherein the nitrogen-rich water-based superfinishing concentrated solution contains 25-30% by mass of mixed extreme pressure additive and 5-10% by mass of penetrant mixture; the mixed extreme pressure additive is prepared from the following raw materials in percentage by mass: 10-20% of fatty acid imidazoline borate, 3-5% ofrosin amide, 3-6% of polyethylene glycol alkyl ether and the balance of water; and the penetrant mixture is a mixture of ethylenediamine tetraacetic acid disodium salt, rare earth compound and ethanol according to any proportion. The nitrogen-rich water-based enhanced superfinishing method adopts nitrogen-rich water-based superfinishing liquid without kerosene, and fine-grained oil stone installed on a vibrating head is utilized to finish the finished surface, so that the process is simple, the operation is easy, the efficiency is high, and the nitrogen-rich water-based enhanced superfinishing method for the alloy workpiece surface and the formula of superfinishing liquid are suitable for large-scale mass production.

Owner:GUANGZHOU UNIVERSITY

Use of polyglycols to control rheology of unit dose detergent compositions

ActiveUS20200199491A1Promote dissolutionPromote hydrationOrganic detergent compounding agentsNon-ionic surface-active compoundsSulfonateLinear alkylbenzene sulfonate

A method for maintaining a consistent, low viscosity profile of a unit dose detergent composition for enhanced hydration and dissolution upon hydration including the steps of: (1) A method for maintaining a consistent, low viscosity profile of a unit dose detergent composition for enhanced hydration and dissolution upon hydration including the steps of: (1) providing the detergent composition including: about 2.5 to about 15 wt. % of a polyglycol, an alkyl-ether sulfate, a linear alkylbenzene sulfonate, and a fatty alcohol ethoxylate, wherein the alkyl-ether sulfate, linear alkylbenzene sulfonate, and fatty alcohol ethoxylate are collectively present in an amount of 30 to 70 wt. %, by weight of the detergent composition; and (2) encapsulating the detergent composition in a pouch made of a water soluble film.

Owner:HENKEL KGAA

A kit for measuring glucose content and its application

ActiveCN112710656BEliminate distractionsImprove accuracyMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPolyethylene oxideActive agent

The invention relates to the technical field of in vitro detection, in particular to a kit for measuring glucose content and its application. The kit includes an anti-chylopathic interference reagent selected from the group consisting of poly(ethylene oxide) fatty alcohol nonionic surfactants, poly(ethylene oxide-propylene oxide) fatty alcohol nonionic surfactants. One or more of the non-ionic surfactants of polyethylene glycol alkyl ethers, mixed fatty acid glycerides non-ionic surfactants. The invention is based on the basic components of the glucose determination kit, and adds 0.01% to 10% of one or several specific surfactants in the detection reagent, so as to eliminate the interference of chyle in the lipid blood sample to the glucose determination, and improve the lipid blood level. The accuracy of glucose detection in the sample; the reagent composition is simple, easy to produce and prepare; the cost is low, and it is easy to commercialize.

Owner:BIOSINO BIO TECH & SCI

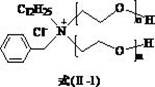

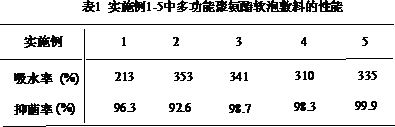

Application of a kind of hydroxyl-terminated polymer in the preparation of multifunctional polyurethane soft foam dressing

ActiveCN112266454BSolve the single functionPharmaceutical delivery mechanismAbsorbent padsPolymer sciencePolyol

The invention discloses an application of a hydroxyl-terminated polymer in the preparation of a multifunctional polyurethane soft foam dressing, which comprises hydrophilic substances including hydroxyl-terminated polyethylene glycol alkyl ether, single-terminated hydroxyl polyvinylpyrrolidone and hydroxyl-terminated polyether quaternary Mix ammonium salt with surfactant and water to make functional foaming component A; then react polyether polyol, chain extender and catalyst with polyisocyanate to prepare polyurethane prepolymer component B; The flexible foaming component A and the polyurethane prepolymer component B are mixed and foamed to prepare a multifunctional polyurethane soft foam plastic, which is used to produce a product with the functions of hydrophilicity, water absorption, moisturizing, antibacterial, sterilizing, hemostasis, and promoting healing. Medical dressing.

Owner:JIANGSU OCEAN UNIV

Antistatic PTT resin

InactiveCN104845247AImprove antistatic performanceStrong impact resistanceGlycidyl methacrylatePolymer science

The invention discloses an antistatic PTT resin, which comprises the following components by mass: 75%-85% of PTT, 8%-12% of glass fiber, 4%-8% of a toughening modification agent, 1%-3% of an antistatic agent, 0.5%-2% of a light stabilizer, 0.1%-0.5% of an antioxidant, and 0.1%-1% of a lubricant. The toughening modification agent is a glycidyl methacrylate grafted ethylene-octene copolymer, and the antistatic agent is one of fatty acid polyethylene glycol ester, polyethylene glycol alkyl ether, and glycerol monostearate. The antistatic PTT resin provided by the invention has excellent antistatic performance and good impact resistance, and also has high strength, strong aging resistance, smooth and clean product surface, and good appearance, thus being easy to popularize.

Owner:王妮娜

Application of hydroxyl-terminated polymer in preparation of multifunctional polyurethane flexible foam dressing

ActiveCN112266454ASolve the single functionPharmaceutical delivery mechanismAbsorbent padsPolymer sciencePolyol

The invention discloses an application of a hydroxyl-terminated polymer in preparation of a multifunctional polyurethane flexible foam dressing. The application comprises the following steps: mixing hydrophilic substances including hydroxyl-terminated polyethylene glycol alkyl ether, single hydroxyl-terminated polyvinylpyrrolidone and hydroxyl-terminated polyether quaternary ammonium salt with a surfactant and water to prepare a functional foaming component A; reacting polyether polyol, a chain extender and a catalyst with polyisocyanate to prepare a polyurethane prepolymer component B; and mixing and foaming the functional foaming component A and the polyurethane prepolymer B to prepare the multifunctional polyurethane flexible foam plastic which is used for producing medical dressings with hydrophilic, water-absorbing, moisturizing, antibacterial, sterilizing, hemostatic and healing-promoting functions.

Owner:JIANGSU OCEAN UNIV

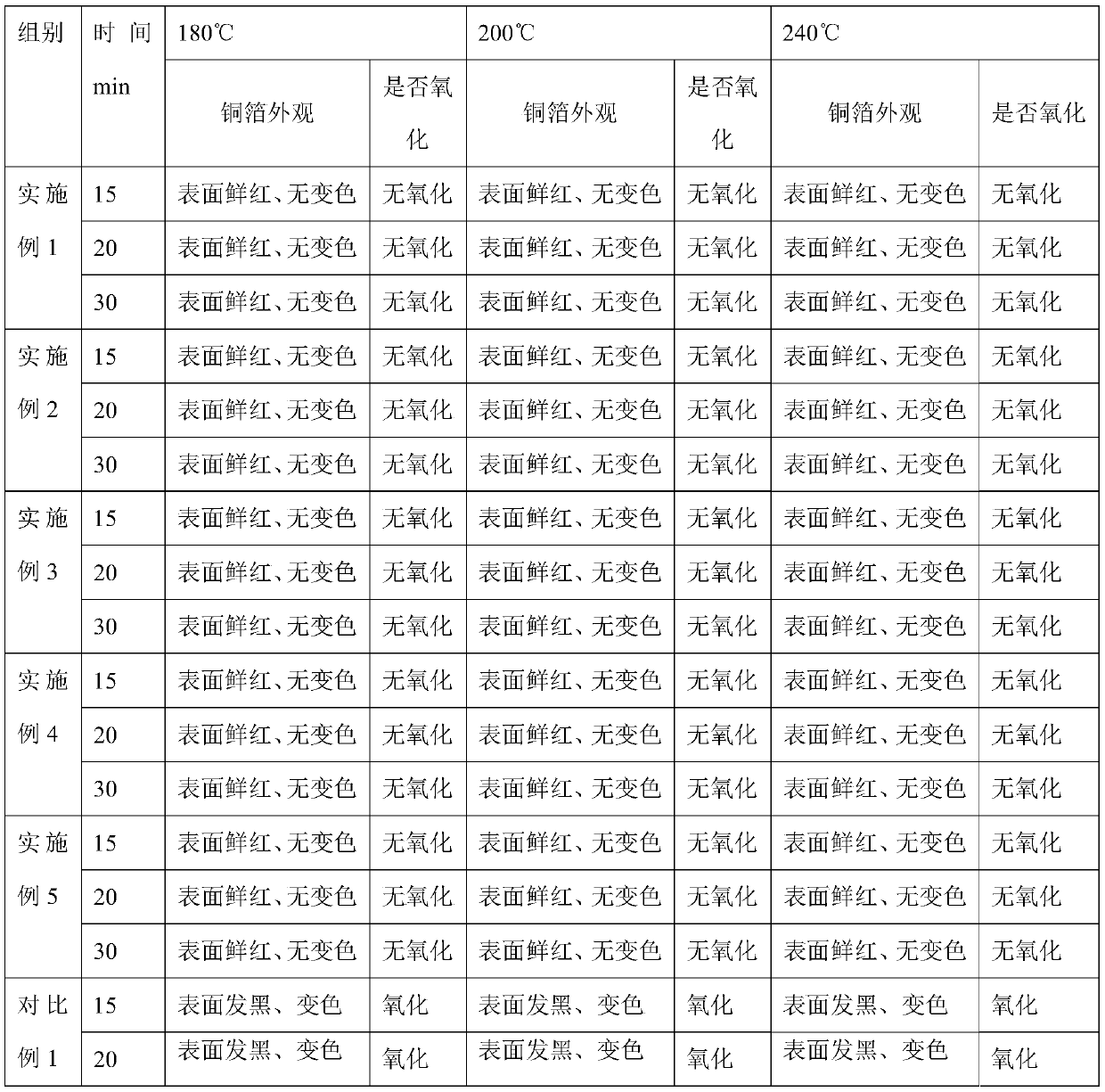

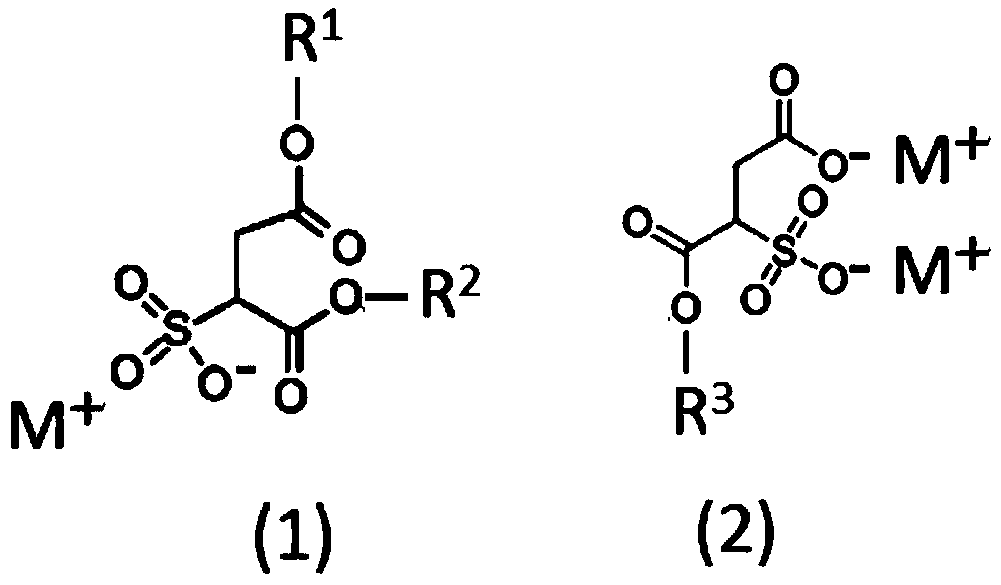

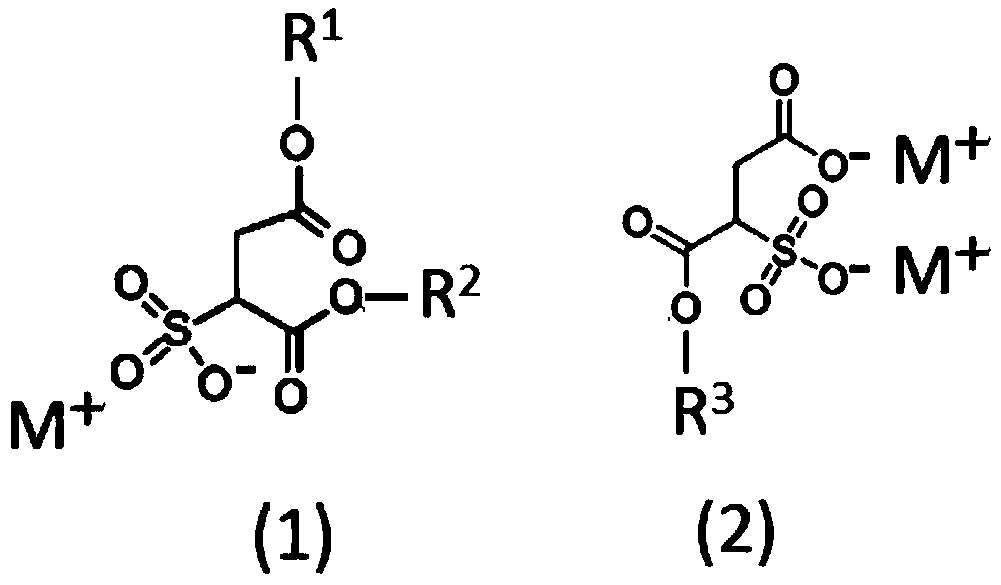

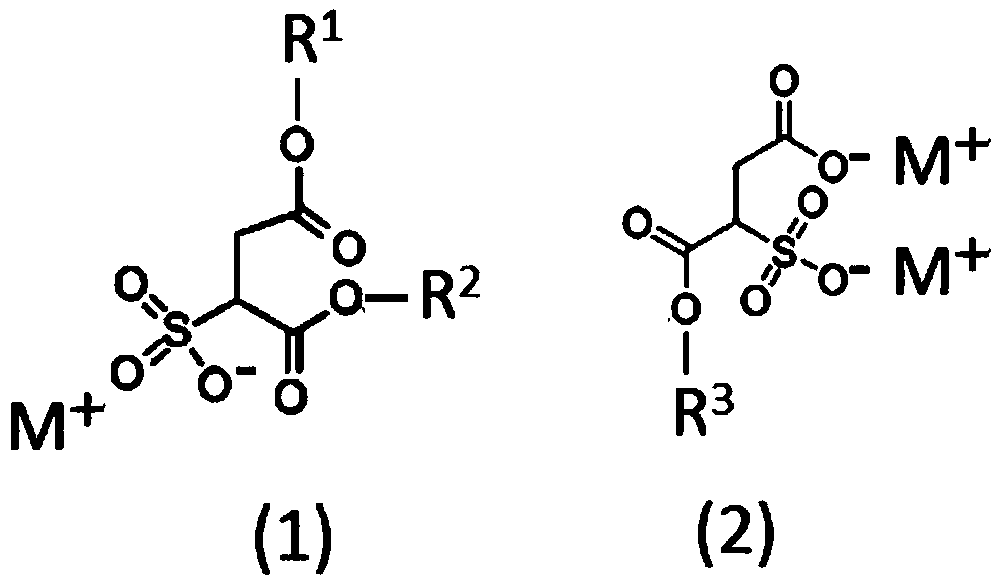

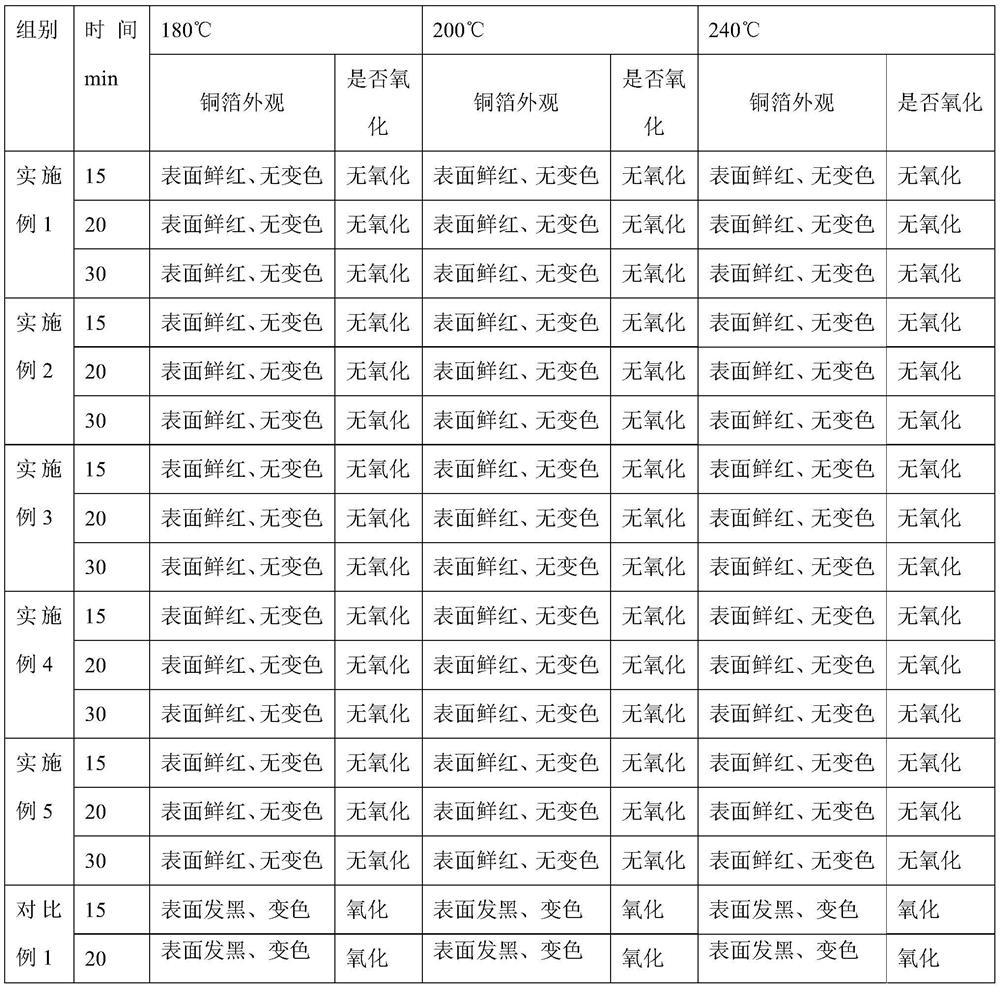

Plating solution of high-temperature-resistance oxidation-resistance alloy copper foil and application thereof

ActiveCN111534839AHigh thermodynamic stabilityGood high temperature corrosion resistanceCitric Acid / tartaric acidCopper foil

The invention discloses a plating solution of high-temperature-resistance oxidation-resistance alloy copper foil and application thereof. The plating solution is prepared from stannous sulfate, zinc sulfate, auxiliary additives, a brightener and water, wherein the auxiliary additives are from at least two of citric acid, tartaric acid, sodium gluconate, ammonium sulfate, triethanolamine, polyethylene glycol alkyl ether and vanilline, and the brightener is peptone and / or gelatin. The application refers to application of the plating solution in preparing the high-temperature-resistance oxidation-resistance alloy copper foil. A manufactured copper foil cladding layer is fine, smooth and bright. The copper foil has high thermodynamic stability and high resistance to high-temperature corrosion,and can be used for manufacturing high-precision printed circuit boards.

Owner:建滔(连州)铜箔有限公司

Super concentrated liquid fabric softening composition in rinsing process

InactiveCN1175093CGood dispersionCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

Super-concentrated liquid rinse cycle fabric softeners are provided which contain more than 35 %, by weight, of a fabric softening system based on an amidoamine fabric softener, such as bis(tallow amidoethyl)-2-hydroxyethyl amine and a quaternary diester fabric softener, such as N-methyl, N,N,N-triethanolamine ditallow ester quaternary ammonium salt. A fatty alcohol ethoxylate surfactant and a polyethylene glycol polymer or a polyethylene glycol alkyl ether polymer are integral components of the liquid composition. The super-concentrated compositions may be used at low levels or may be further diluted prior to use.

Owner:COLGATE PALMOLIVE CO

A kind of preparation method and application of the second monomer of solid-solid phase change material of acrylonitrile-based copolymer

ActiveCN103965464BGood energy storageGood heat release functionPreparation from carboxylic acid halidesMonocomponent synthetic polymer artificial filamentDecompositionAcrylonitrile

The invention discloses a preparation method of a second monomer for an acrylonitrile-based copolymer solid-solid phase change material, a method for preparing the acrylonitrile-based copolymer solid-solid phase change material from the second monomer, and a method for preparing an energy-storage and temperature-adjustment fiber / film from the phase change material prepared from the second monomer. The second monomer is prepared by the steps of enabling polyoxyethylene alkyl ether to react with sodium in methylbenzene, then enabling the reactant to react with an allyl monomer containing acyl chloride groups to obtain a crude product, and washing and carrying out liquid separation on the crude product. The acrylonitrile-based copolymer solid-solid phase change material prepared from the second monomer has the melting point being lower than the decomposition temperature and is applicable to melt spinning. The fiber / film with favorable energy-storage and temperature-adjustment performances can be prepared by mixing the acrylonitrile-based copolymer solid-solid phase change material with a thermal stabilizer and then spinning and filming under molten conditions.

Owner:TIANJIN POLYTECHNIC UNIV

Modified polyvinyl chloride composite film and preparation method thereof

InactiveCN104861348AImprove smoothnessExcellent heat and weather resistanceComposite filmPolyvinyl chloride

The invention discloses a modified polyvinyl chloride composite film and a preparation method thereof. The modified polyvinyl chloride composite film comprises, by mass, 35-60% of polyvinyl chloride, 15-20% of polyvinyl alcohol, 10-15% of polyvinylpyrrolidone, 2-8% of erucamide, 5-10% of ethylene-octylene copolymer grafted maleic anhydride, 2-5% of nanometer silica, 1-3% of polyethylene glycol alkyl ether, 1-2% of a light stabilizer 944, 1-2% of silicone powder and 0.5-1% of fatty alcohol polyoxyethylene ether. The modified polyvinyl chloride composite film has the advantages of good slip effect, excellent antistatic performance, good heat and weather resistance, good impact toughness, good tensile strength, high elongation at break, good molding, and simple preparation process.

Owner:殷培花

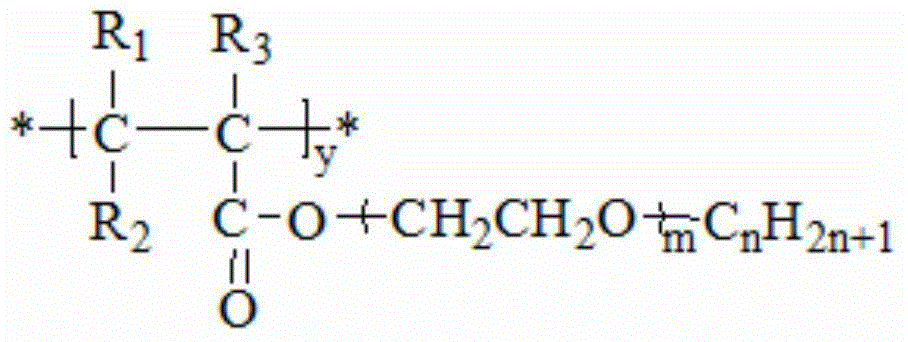

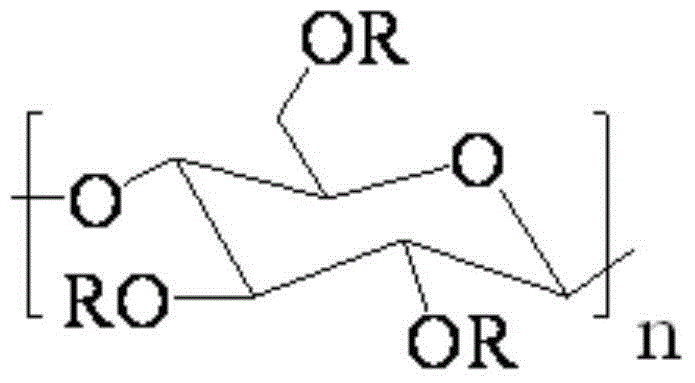

A thermoplastic cellulose-based solid-solid phase change material and preparation method thereof

ActiveCN103484064BQuick responseImprove heat storage capacityHeat-exchange elementsCross-linkThermoplastic

The invention discloses a thermoplastic cellulose-based solid-solid phase transition material and a preparation method thereof. The preparation method comprises the following steps: 1, drying cellulose or a cellulose derivative; 2, respectively dissolving a cross-linking agent and polyethylene glycol alkyl ether in an organic solvent I to obtain a cross-linking agent solution and a polyethylene glycol alkyl ether solution, adding the polyethylene glycol alkyl ether to the cross-linking agent solution in a dropwise manner, adding a catalyst, and reacting for 0.5-10h to obtain a prepolymer solution, wherein a mole ratio of the polyethylene glycol alkyl ether to the cross-linking agent is 1:1; and 3, dissolving cellulose in an ionic liquid to obtain a cellulose solution, adding the prepolymer solution, acid anhydride and a catalyst to the above obtained cellulose solution, carrying out a polymerization reaction for 2-24h to obtain a finally obtained mixture, adding the finally obtained mixture to deionized water or an organic solvent II for precipitation, repeatedly washing the above obtained precipitate with deionized water 2-3 times, and carrying out vacuum drying to obtain the thermoplastic cellulose-based solid-solid phase transition material. The phase transition material has a good thermal stability and a melting processing performance, and can be blended with a thermoplastic copolymer matrix for melting processing.

Owner:TIANJIN POLYTECHNIC UNIV +1

Gel ink composition for gel pens, preparation method thereof, and gel pen

The present invention provides a gel ink composition. 100 parts by mass of the gel ink composition comprise, by mass, 2-10 parts of a red organic pigment, 5-25 parts of a humectant, 0.1-1.5 parts of apreservative, 0.1-4 parts of a pH adjuster, 1-10 parts of a penetrant, 1-5 parts of a tackifier, 0.5-7 parts of a dispersant, 0.1-0.5 part of an antifoaming agent and 37-90 parts of deionized water,and the penetrant is at least one selected from alkyl sulfosuccinate compounds and oligoethylene glycol alkyl ether compounds.

Owner:常熟美克尼化工有限公司

PTT/inorganic particle blend and preparation method therefor

The invention discloses a PTT / inorganic particle blend and a preparation method therefor. The PTT / inorganic particle blend comprises the following ingredients, by weight, 75%-90% of PTT, 5%-15% of inorganic particles, 2%-5% of polyethylene glycol, 0.5%-2% of antistatic agent, 0.5%-2% of light stabilizing agents, 0.1%-0.5% of anti-oxidants and 0.1%-1% of lubricants. The inorganic particles are alumina nanoparticles with surfaces modified by 2% of silane coupling agents and with a particle size of 30-50 nanometers. The antistatic agent is one selected from fatty acid polyethylene glycol ester, polyethylene glycol alkyl ether, N,N-polyethylene glycol alkylamine and glycerol monostearate. The beneficial effects are that the PTT / inorganic particle blend has excellent mechanical properties and heat resistance, the antistatic effects are good, the aging resistance is high, the size stability is good, the adaptability is high, the cost is low, and popularization is easy.

Owner:QINGDAO XINZHAN PLASTIC

A kind of plating solution and application of high temperature resistant and oxidation resistant alloy copper foil

ActiveCN111534839BHigh thermodynamic stabilityGood high temperature corrosion resistanceCitric Acid / tartaric acidCopper foil

The invention discloses a high-temperature-resistant and anti-oxidation alloy copper foil plating solution and its application. The plating solution is composed of the following raw materials: stannous sulfate, zinc sulfate, auxiliary additives, brighteners and water; the auxiliary additives are At least two of citric acid, tartaric acid, sodium gluconate, ammonium sulfate, triethanolamine, polyethylene glycol alkyl ether and vanillin; the brightener is peptone and / or gelatin; Application in the preparation of high temperature resistant and oxidation resistant alloy copper foil. The copper foil coating produced by the invention is dense, smooth and bright; the copper foil has high thermodynamic stability, and the zinc-tin alloy coating also has good high-temperature corrosion resistance, and can be used in the manufacture of high-precision printed circuit boards.

Owner:建滔(连州)铜箔有限公司

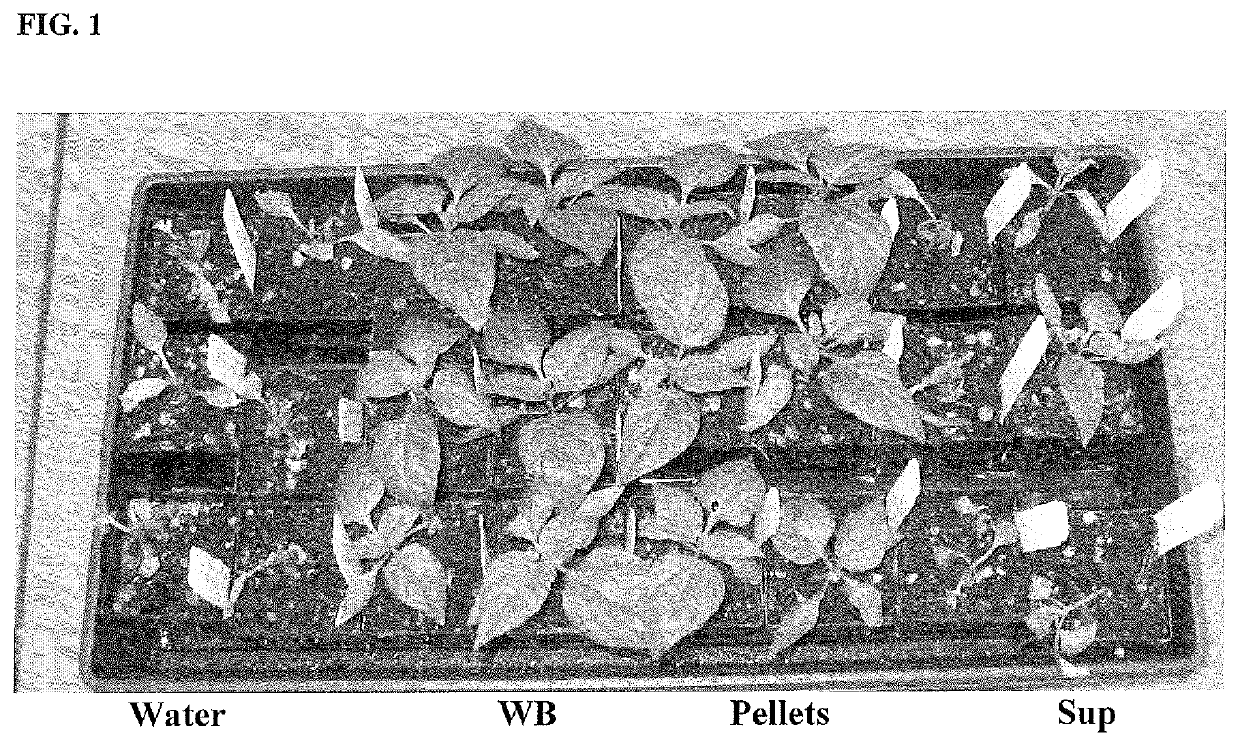

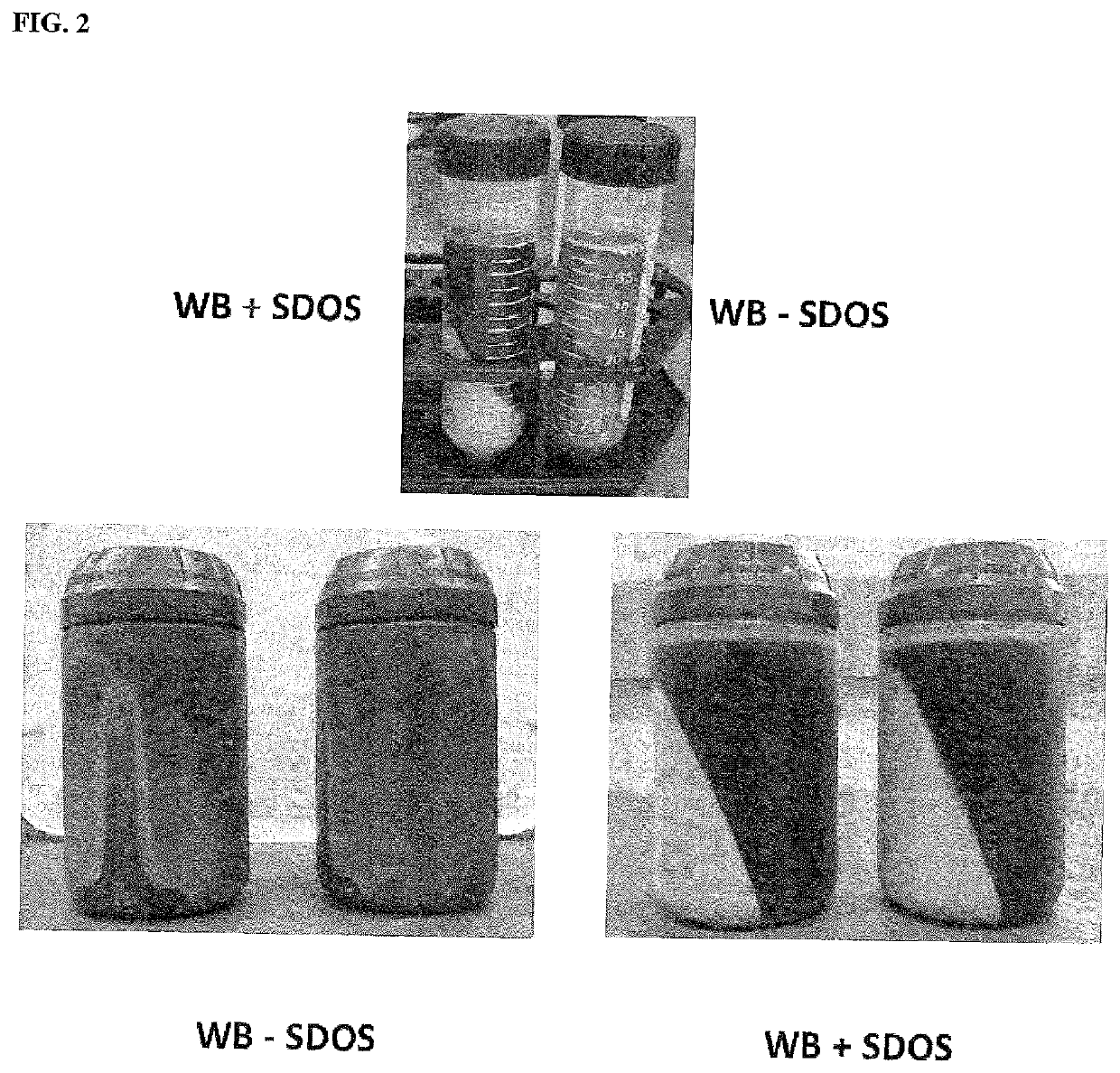

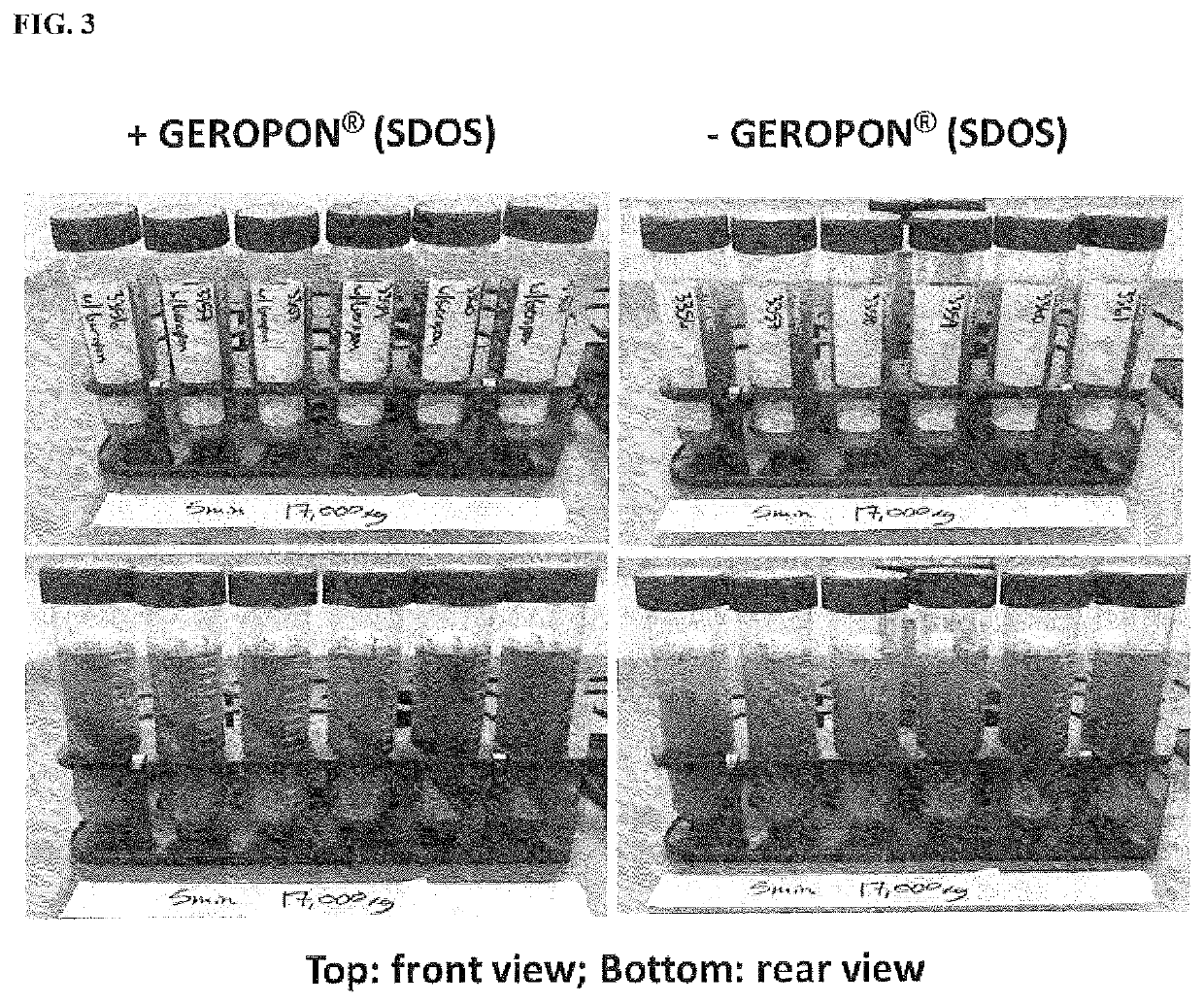

Method of purifying antifungal compounds and exopolysaccharides from a microbial cell culture

The present invention provides a method of enriching a lipopeptide in a microbial cell culture, the method comprising mixing an amphiphilic sulfonate and / or an amphiphilic sulfate with the cell culture to induce the formation of aggregates containing the lipopeptide, centrifuging the cell culture to generate a supernatant fraction and a pellet fraction, separating the pellet fraction from the supernatant fraction, and mixing the pellet fraction with a polyoxyethylene glycol alkyl ether to release the lipopeptide from the aggregates. Also provided is a method of purifying an exopolysaccharide from a microbial cell culture, the method comprising mixing an amphiphilic sulfonate and / or an amphiphilic sulfate with the cell culture to induce the formation of aggregates, centrifuging the cell culture to generate a supernatant fraction and a pellet fraction, separating the supernatant fraction from the pellet fraction, adding alcohol to the supernatant fraction to precipitate the exopolysaccharide; and removing the precipitated exopolysaccharide from the supernatant fraction.

Owner:BAYER CROPSCI LP

Bondable blood-friendly polymer and preparing method thereof

ActiveUS10047242B2Reduce coatingOvercomes shortcomingEster polymer adhesivesCoatingsMethacrylateSilanes

Owner:ANQING GOUYOU BIOMATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com