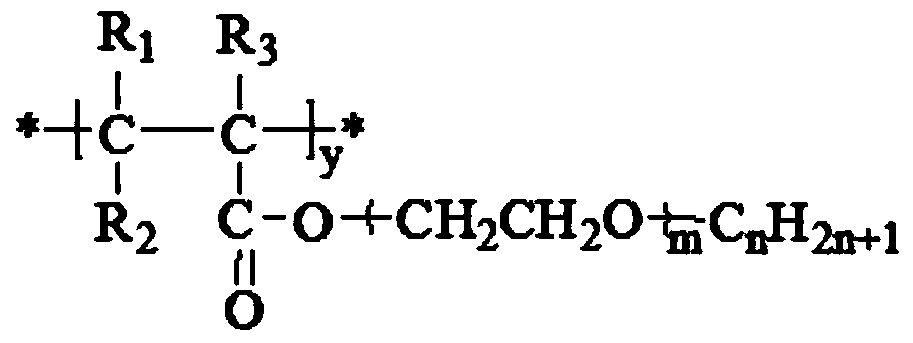

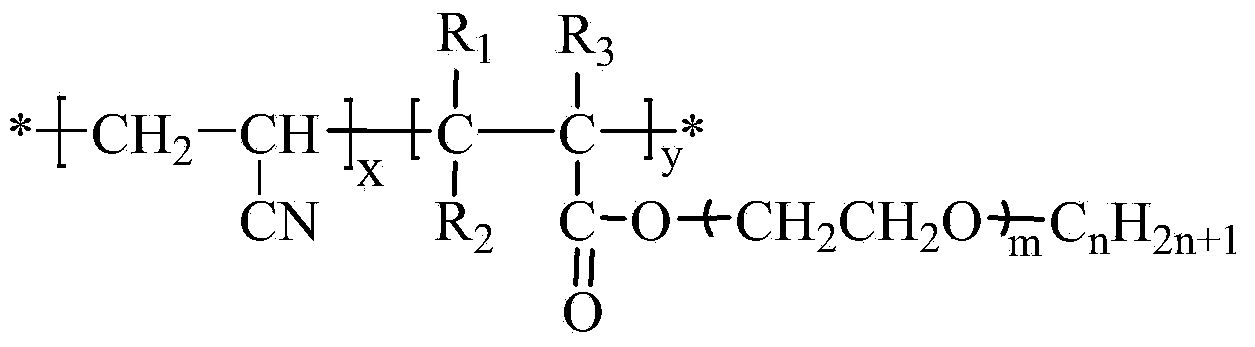

Preparation method and application of second monomer for acrylonitrile-based copolymer solid-solid phase change material

A technology of acrylonitrile-based copolymers and phase-change materials, which is applied to the preparation of carboxylic acid halides, materials for heat exchange, chemical instruments and methods, etc., and can solve problems such as acrylonitrile-based copolymer phase-change materials that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0064] 1) Add diethylene glycol n-hexadecyl ether and toluene to a reaction device equipped with a thermometer and a reflux condenser after anhydrous drying, wherein the concentration of diethylene glycol n-hexadecyl ether in toluene is 80wt %, under the protection of nitrogen, stir and increase the temperature of the system to 80 ° C, add elemental sodium and diethylene glycol n-hexadecyl ether to react, wherein the molar ratio of sodium to diethylene glycol n-hexadecyl ether is 5:1; after no bubbles emerge from the liquid surface, let it cool down to room temperature, filter to remove residual sodium, and obtain the reaction stock solution;

[0065] 2) Prepare an acryloyl chloride-toluene solution with a concentration of 10 wt%, the molar ratio of acryloyl chloride to diethylene glycol n-hexadecyl ether is 10:90, and slowly add the acryloyl chloride-toluene solution...

Embodiment 2

[0076] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0077] In embodiment 1, diethylene glycol n-hexadecyl ether is replaced by polyethylene glycol n-docosyl ether (HO(CH 2 CH 2 O) 600 C 22 h 45 ), the temperature was 130°C when elemental sodium was added, and the molar ratio of elemental sodium to polyethylene glycol n-docosyl ether was 1:5; the remaining conditions were the same as in Example 1 to prepare the second monomer with phase transition characteristics- Polyethylene glycol n-behenyl ether monoacrylate with a yield of 85%.

[0078] ②Preparation of acrylonitrile-based copolymer solid-solid phase change materials by emulsion polymerization

[0079] 1) In the reaction vessel, add deionized water with 15 times the mass of the monomer and a compounded emulsifier accounting for 1.5% of the mass of the monomer (the compounded emulsifier is sodium lauryl sulfate and polystyrene with a mass ratio of 7:3 Ethylene ...

Embodiment 3

[0088] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0089] 1) Docosanol (C 42 h 85 OH) and toluene are added to the reaction device equipped with a thermometer and a reflux condenser after anhydrous drying treatment, wherein docosanol (C 42 h 85 OH) concentration in toluene is 50wt%, under the protection of nitrogen, stir and increase the temperature of the system to 110 ° C, add elemental sodium and tetracosanol (C 42 h 85 OH) reacted, wherein the molar ratio of sodium to docosanol was 1.8:1; after no bubbles emerged from the liquid surface, it was left to cool to room temperature, filtered to remove residual sodium, and the reaction stock solution was obtained;

[0090] 2) preparation concentration is the ethacryloyl chloride-toluene solution of 30wt%, ethacryloyl chloride and tetradocosanol (C 42 h 85 The molar ratio of OH) is 45:55. Under the condition of ice-water bath, the ethacryloyl chloride-toluene solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of fusion | aaaaa | aaaaa |

| Endothermic temperature | aaaaa | aaaaa |

| Exothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com