Application of polyurethane-based interpenetrating network polymer in surface modification of medical catheter

An interpenetrating network and polyurethane-based technology, applied in the field of functional polymer materials, can solve the problems of complex process, high cost, storage stability of isocyanate-terminated prepolymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

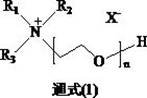

[0068] Step 1: Preparation of polyether type cross-linked polyurethane-1.

[0069] Add 25 kg of polyether diol DL-2000D with a mass average molecular weight of 2000 produced by Shandong Bluestar Dongda Chemical Co., Ltd. and 3.5 kg of trimethylolethane into the reaction kettle, and vacuum dry at 100°C to remove water for 2.5 hours , after which the material in the reactor was cooled to room temperature, N 2 Under protection and stirring, add 0.02 kg of dibutyltin dilaurate and 0.05 kg of triethylamine. After stirring evenly, continuously add a mixture of 30 kg of toluene diisocyanate (TDI80 / 20) and 30 kg of dehydrated acetone, and gradually increase the The temperature of the material is 60-65°C for 1 hour, and 70-80°C for 2 hours to prepare a viscous solution of polyether type cross-linked polyurethane-1 for later use.

[0070] Step 2: Preparation of functional polyurethane prepolymer-1

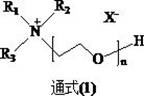

[0071] Add 20 kg of 6950F brand toluene isocyanate trimer with a solid content of abou...

Embodiment 2

[0078] Embodiment 2 Preparation of polyurethane-based interpenetrating network polymer-2

[0079] According to the method and operation steps of Example 1, the polyether diol DL-2000D with an average molecular weight of 2000 in Step 1 of Example 1 was replaced with hydroxyl-terminated polybutadiene diol-4000 (Shenzhen Hongyuan New Material Technology Co., Ltd.), the

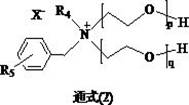

[0080] Described trimethylolethane is changed into triethanolamine, and the quaternary ammonium cationic polyether glycol of structure shown in the formula (2-1) in embodiment 1 step 2 is changed into the quaternary ammonium cationic polyether glycol of structure shown in formula (2-2) Ammonium cationic polyether diols to prepare a viscous solution of polyurethane-based interpenetrating network polymer-2. Wherein the structure of the quaternary ammonium cationic polyether diol is shown in formula (2-2), and p+q in the formula (2-2) is equal to 20.

[0081]

Embodiment 3

[0082] Example 3 Preparation of Polyurethane-based Interpenetrating Network Polymer-3

[0083] According to the method and operating steps of Example 1, the polyether diol DL-2000D with the average molecular weight of 2000 in Step 1 of Example 1 was replaced with Polyethylene Glycol-4000 (Tianjin Zhonghe Shengtai Chemical Co., Ltd.), The quaternary ammonium cationic polyether diol of the structure shown in the formula (2-1) in the step 2 of embodiment 1 is changed into the quaternary ammonium cationic polyether diol of the structure shown in the formula (2-2), makes polyurethane base Viscous solution of interpenetrating network polymer-3. Wherein the structure of the quaternary ammonium cationic polyether diol is shown in formula (2-2), and p+q in the formula (2-2) is equal to 20.

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com