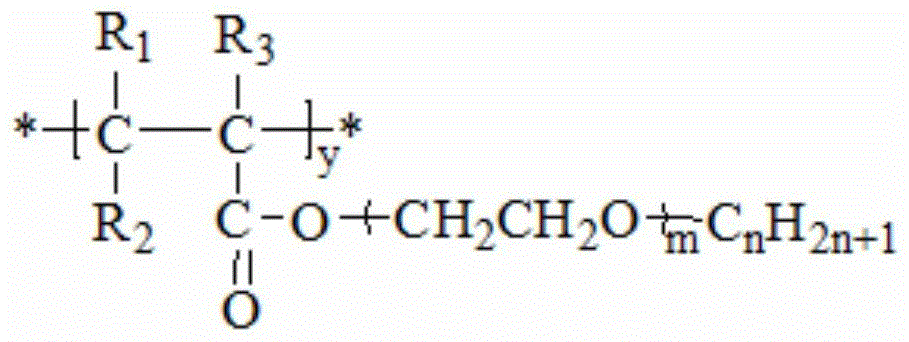

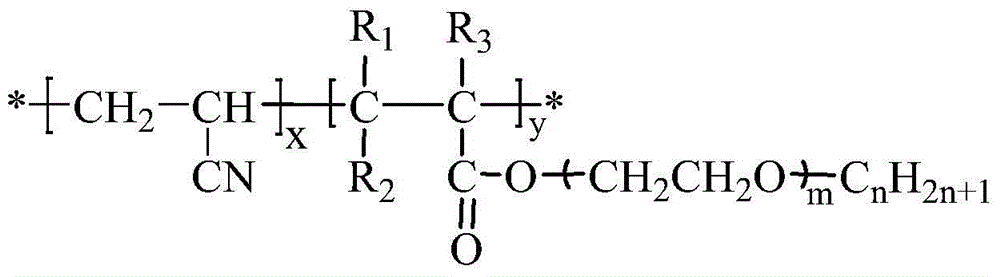

A kind of preparation method and application of the second monomer of solid-solid phase change material of acrylonitrile-based copolymer

A technology of acrylonitrile-based copolymer and phase change material, which is applied in the preparation of carboxylic acid halide, heat exchange materials, chemical instruments and methods, etc., can solve the problems such as phase change materials of acrylonitrile-based copolymer that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0064] 1) Add diethylene glycol n-hexadecyl ether and toluene to a reaction device equipped with a thermometer and a reflux condenser after anhydrous drying, wherein the concentration of diethylene glycol n-hexadecyl ether in toluene is 80wt %, under the protection of nitrogen, stir and increase the temperature of the system to 80 ° C, add elemental sodium and diethylene glycol n-hexadecyl ether to react, wherein the molar ratio of sodium to diethylene glycol n-hexadecyl ether is 5:1; after no bubbles emerge from the liquid surface, let it cool down to room temperature, filter to remove residual sodium, and obtain the reaction stock solution;

[0065] 2) Prepare an acryloyl chloride-toluene solution with a concentration of 10 wt%, the molar ratio of acryloyl chloride to diethylene glycol n-hexadecyl ether is 10:90, and slowly add the acryloyl chloride-toluene solution...

Embodiment 2

[0076] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0077] In embodiment 1, diethylene glycol n-hexadecyl ether is replaced by polyethylene glycol n-docosyl ether (HO(CH 2 CH 2 O) 600 C 22 h 45 ), the temperature was 130°C when elemental sodium was added, and the molar ratio of elemental sodium to polyethylene glycol n-docosyl ether was 1:5; the remaining conditions were the same as in Example 1 to prepare the second monomer with phase transition characteristics- Polyethylene glycol n-behenyl ether monoacrylate with a yield of 85%.

[0078] ②Preparation of acrylonitrile-based copolymer solid-solid phase change materials by emulsion polymerization

[0079] 1) In the reaction vessel, add deionized water with 15 times the mass of the monomer and a compounded emulsifier accounting for 1.5% of the mass of the monomer (the compounded emulsifier is sodium lauryl sulfate and polystyrene with a mass ratio of 7:3 Ethylene ...

Embodiment 3

[0088] ①Preparation of the second monomer of acrylonitrile-based copolymer solid-solid phase change material

[0089] 1) Docosanol (C 42 h 85 OH) and toluene are added to the reaction device equipped with a thermometer and a reflux condenser after anhydrous drying treatment, wherein docosanol (C 42 h 85 OH) concentration in toluene is 50wt%, under the protection of nitrogen, stir and increase the temperature of the system to 110 ° C, add elemental sodium and tetracosanol (C 42 h 85 OH) reacted, wherein the molar ratio of sodium to docosanol was 1.8:1; after no bubbles emerged from the liquid surface, it was left to cool to room temperature, filtered to remove residual sodium, and the reaction stock solution was obtained;

[0090] 2) preparation concentration is the ethacryloyl chloride-toluene solution of 30wt%, ethacryloyl chloride and tetradocosanol (C 42 h 85 The molar ratio of OH) is 45:55. Under the condition of ice-water bath, the ethacryloyl chloride-toluene solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

| exothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com