A kind of plating solution and application of high temperature resistant and oxidation resistant alloy copper foil

A technology of oxidation resistance and high temperature resistance, which is applied in the field of electroplating, can solve the problems of electrolytic copper foil resistance to chemicals and high temperature resistance and oxidation resistance, and achieve fine coating, high thermodynamic stability, and good high temperature corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

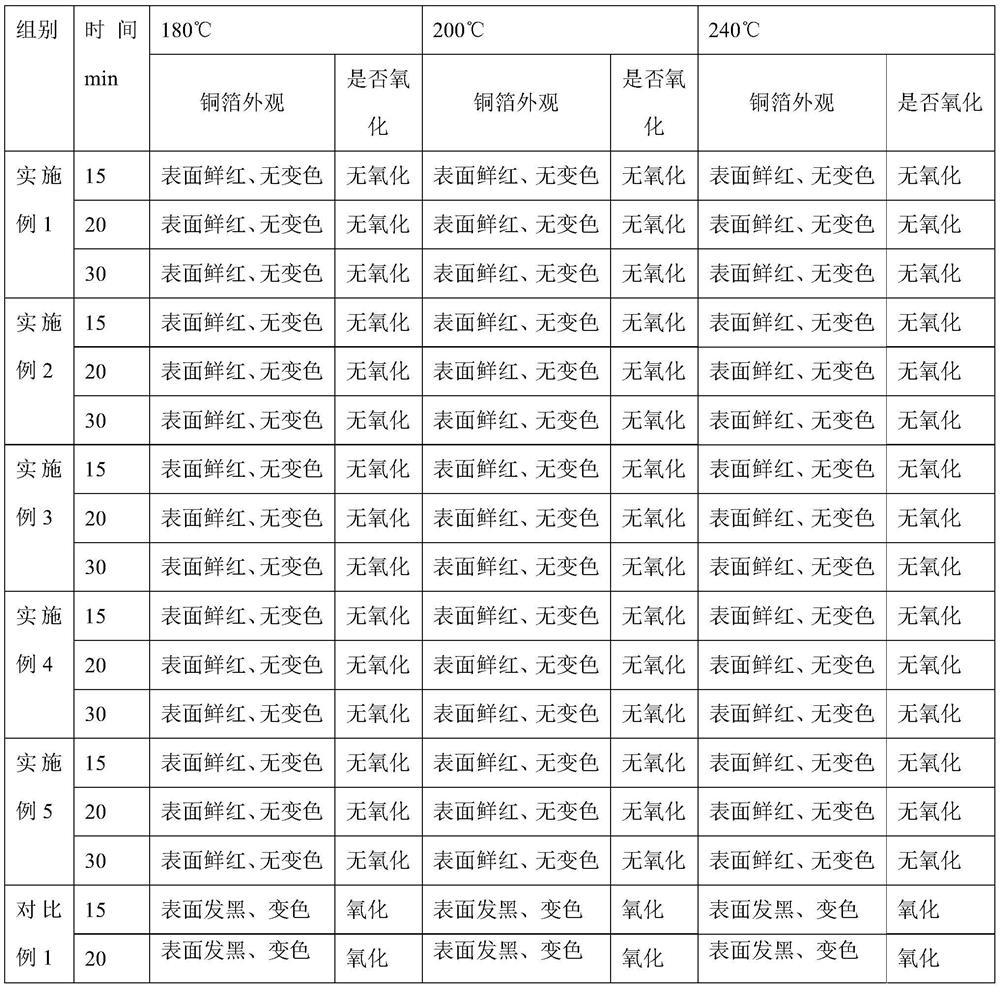

[0040] Embodiment 1-5 A kind of high-temperature-resistant oxidation-resistant alloy copper foil plating solution and its preparation method

[0041] Embodiments 1-5 are the components, consumption and electroplating process parameters of the plating solution, as shown in Table 1. Among them, " / " indicates that it does not exist.

[0042] Table 1

[0043] unit Example 1 Example 2 Example 3 Example 4 Example 5 Stannous Sulfate SnSO 4

[0044] The preparation method of the above-mentioned high-temperature-resistant and oxidation-resistant alloy copper foil includes conventional steps such as pickling, roughening, sealing, weak roughening, zinc-tin alloy plating, passivation, water washing, surfactant treatment, and drying. The zinc-tin alloy step adopts the plating solution and electroplating process parameters in the above table, the anode plate is a titanium plate, and a 35-micron high-temperature-resistant and oxidation-resistant alloy copper foil...

Embodiment 6-10

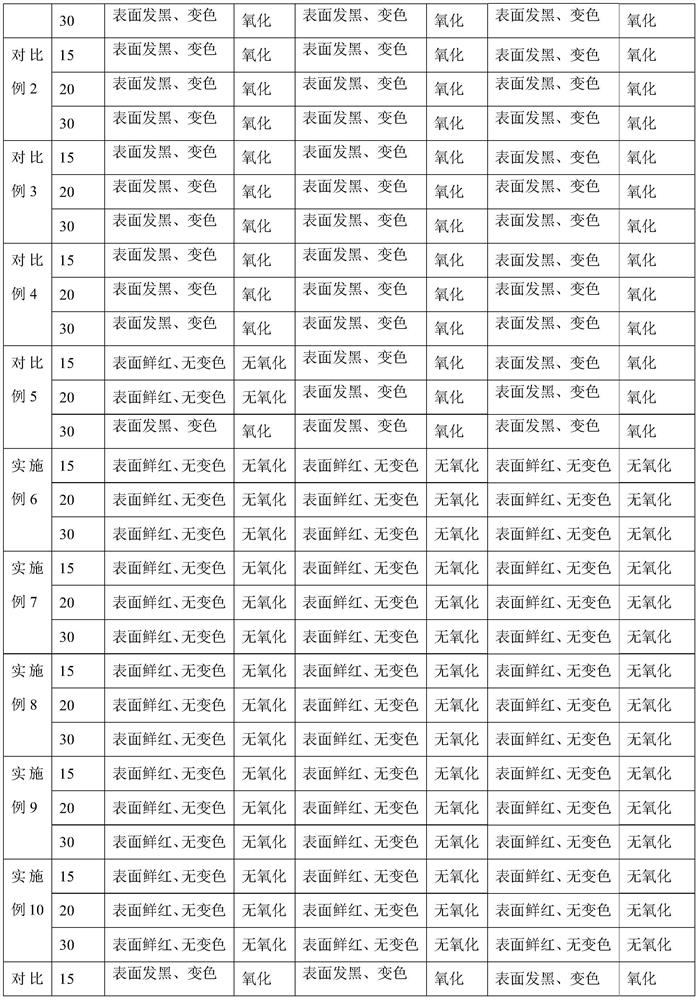

[0055] Embodiment 6-10 A kind of plating solution of high temperature resistance and oxidation resistance alloy copper foil and its preparation method

[0056] The components, consumption and electroplating process parameters of the plating solution are as shown in Table 2. Among them, " / " indicates that it does not exist.

[0057] Table 2

[0058] unit Example 6 Example 7 Example 8 Example 9 Example 10 Stannous Sulfate SnSO 4

[0059] The preparation method of the above-mentioned high-temperature-resistant and oxidation-resistant alloy copper foil includes conventional steps such as pickling, roughening, sealing, weak roughening, zinc-tin alloy plating, passivation, water washing, surfactant treatment, and drying. The zinc-tin alloy step adopts the plating solution and parameters in the above table, the anode plate is a zinc plate, and a 35-micron high-temperature-resistant and oxidation-resistant alloy copper foil is prepared.

Embodiment 11-15

[0068] Example 11-15 A plating solution for high temperature resistant and oxidation resistant alloy copper foil and its preparation method

[0069] The components, consumption and electroplating process parameters of the plating solution are as shown in Table 3. Among them, " / " indicates that it does not exist.

[0070] table 3

[0071] unit Example 11 Example 12 Example 13 Example 14 Example 15 Stannous Sulfate SnSO 4

[0072] The preparation method of the above-mentioned high-temperature-resistant and oxidation-resistant alloy copper foil includes conventional steps such as pickling, roughening, sealing, weak roughening, zinc-tin alloy plating, passivation, water washing, surfactant treatment, and drying. The zinc-tin alloy step adopts the plating solution and parameters in the above table, the anode plate is a titanium plate, and a 35-micron high-temperature-resistant and oxidation-resistant alloy copper foil is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com