Nitrogen-rich water-based enhanced superfinishing method for alloy workpiece surface and formula of superfinishing liquid

A workpiece surface, nitrogen-enriched technology, used in superfinishing machines, metal processing equipment, metal material coating processes, etc., can solve the problems of inability to obtain high precision, unsuitable for superfinishing of workpiece surfaces, and improve surface roughness. Degree and shape accuracy, improved surface strength, low roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

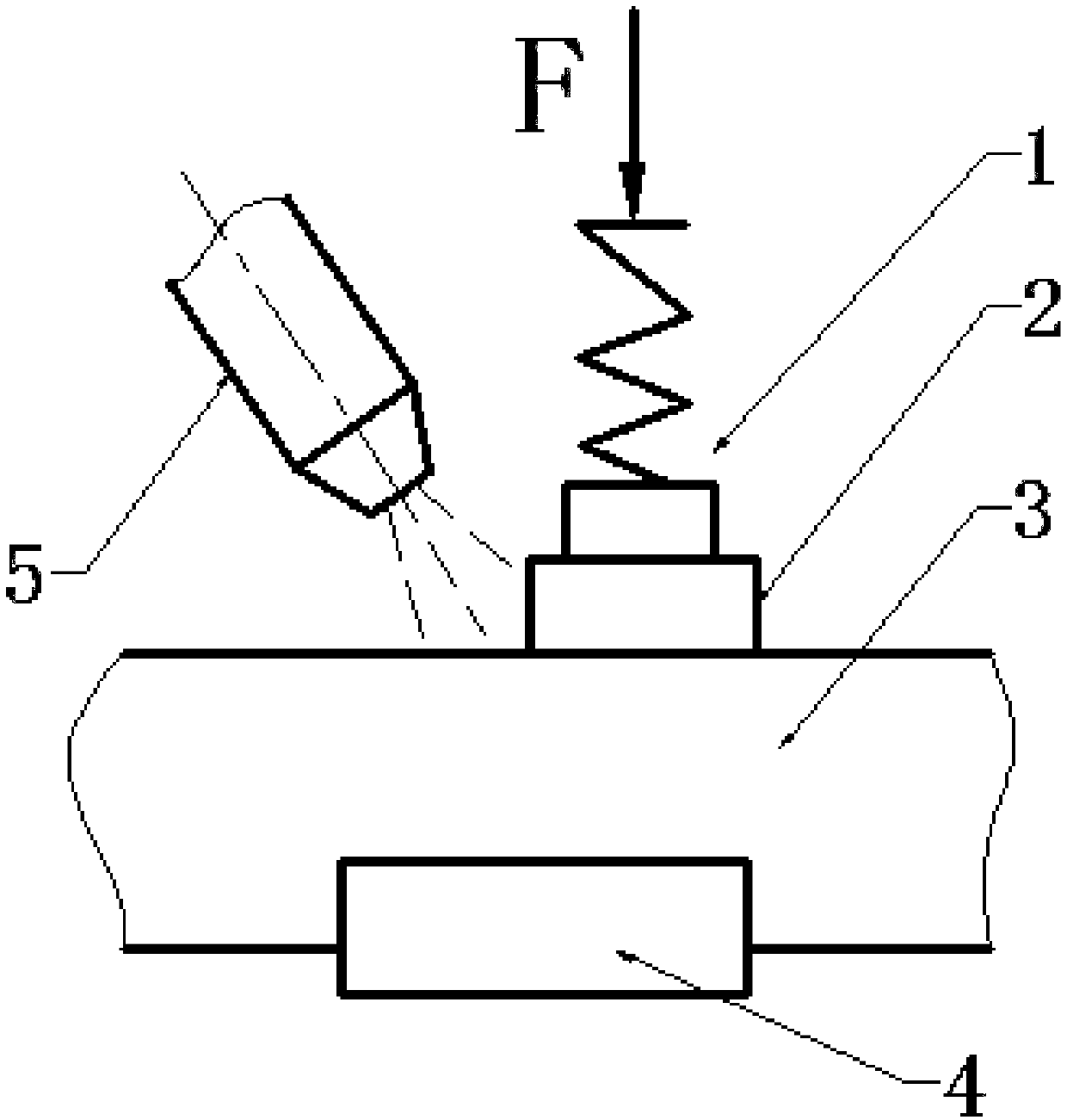

Image

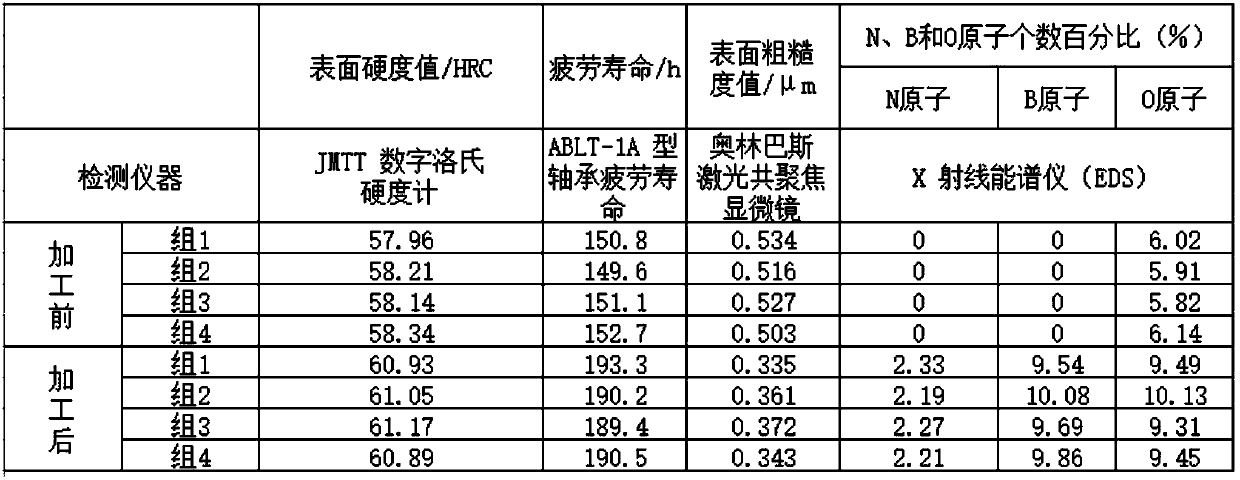

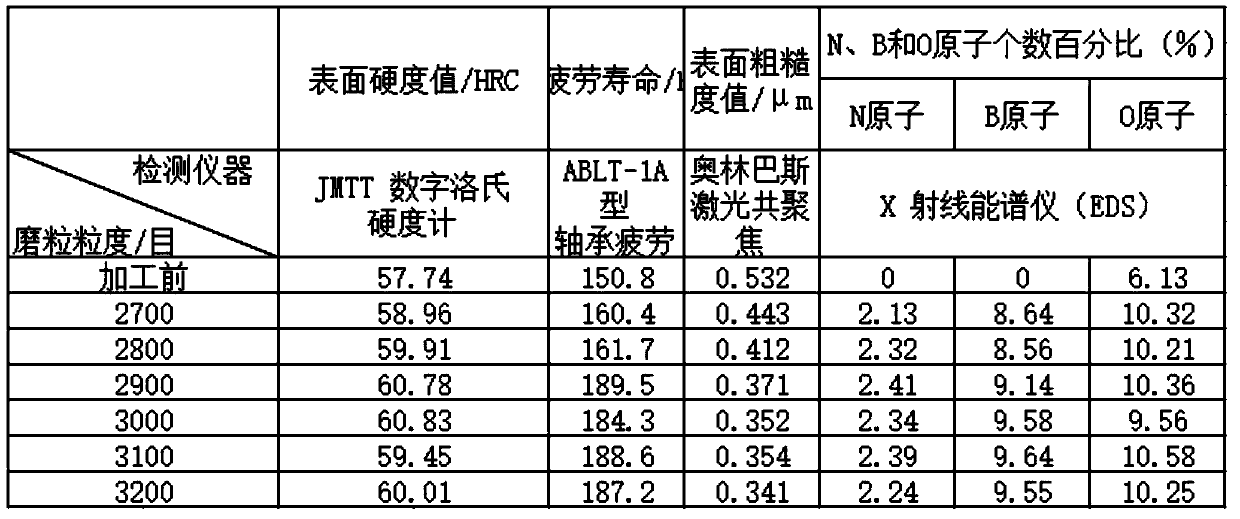

Examples

Embodiment 1

[0032] (1) Preparation of nitrogen-rich water-based enhanced super finishing fluid

[0033] Add 15% fatty acid imidazoline borate, 4% rosin amide, and 5% polyethylene glycol alkyl ether to 76% water according to mass percentage and mix evenly to obtain mixed extreme pressure additives;

[0034] According to mass percentage, 25% mixed extreme pressure additives, 10% penetrant mixture, 1.2% fatty alcohol polyoxyethylene ether, 0.5% benzotriazole, 0.5% sodium alkyl sulfonate, 0.3% Sodium benzoate, 0.8% disodium ethylenediaminetetraacetate, 5% triethanolamine, 5% borax, 0.2% silicone, 1% NaOH, brown corundum 3% are added to 47.5% water and stirred evenly to get Nitrogen-rich water-based superfine concentrate;

[0035] The penetrant mixture is a mixture of disodium ethylenediaminetetraacetic acid, rare earth compounds and ethanol in any ratio;

[0036] Add 7% of the nitrogen-rich water-based superfinishing concentrate to 93% tap water according to mass percentage and stir evenly to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com