A kind of high-efficiency anti-sticking kettle agent for production of pvc suspension polymerization and preparation method thereof

An anti-adhesive kettle agent and suspension polymerization technology, applied in the direction of coating, etc., can solve the problems of difficult to meet the production requirements of PVC polymerization, poor wall coating effect, poor anti-sticking effect, etc. Good effect, the effect of improving the anti-sticking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

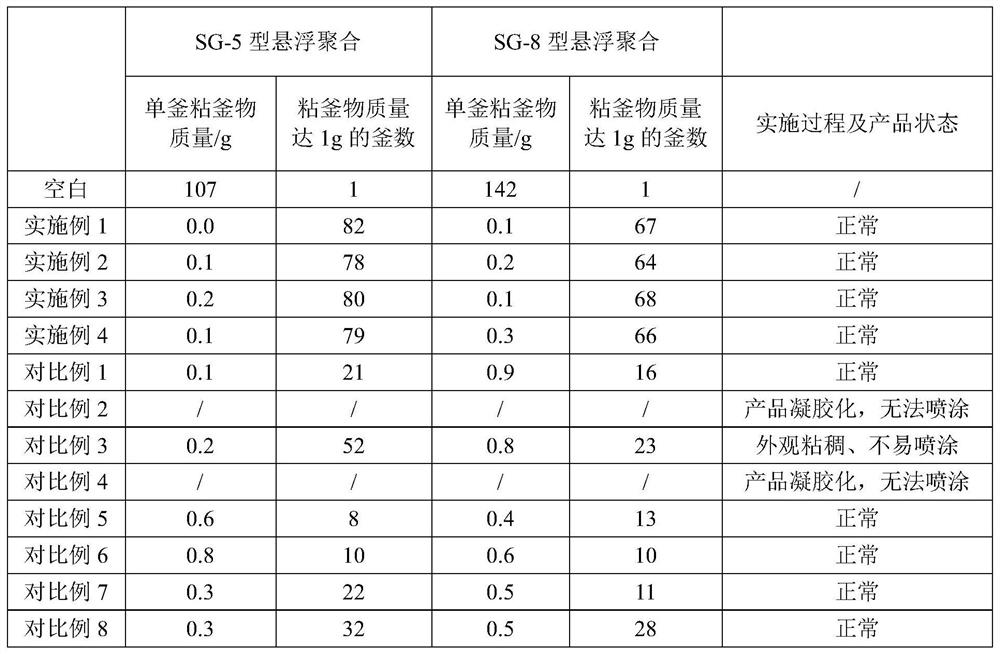

Examples

preparation example Construction

[0033] The present invention provides a method for preparing the above-mentioned high-efficiency anti-sticking agent. The method has the characteristics of simple production process, easy-to-obtain raw materials, low product use cost, and convenient industrialization and application. It specifically includes the following steps:

[0034] (1) Add water to the reaction kettle first, start stirring, the stirring speed is 2500~3000r / min, and the stirring time is 15~30min. The temperature was raised to 65~70°C, and nitrogen gas was continuously purged.

[0035] (2) Add the 1, 4, 5, 8-tetrahydroxynaphthalene and sodium hydroxide in the prescribed amount into the kettle, and stir until they are completely dissolved.

[0036] (3) Mix and dissolve o-hydroxybenzaldehyde, sodium formaldehyde sulfoxylate and part of deionized water, add it dropwise to the reaction kettle, and keep it warm at 70~75°C for 2.5~3h.

[0037] (4) The temperature of the reaction kettle is raised to 90°C, and 1-na...

Embodiment 1

[0044] The composition and ratio of the anti-sticking agent are: 5% o-hydroxybenzaldehyde, 5% 1, 4, 5, 8-tetrahydroxynaphthalene, 2% 1-naphthol-4-carboxylic acid, sodium formaldehyde sulfoxylate 2%, polyvinyl alcohol 2%, sodium hydroxide 2%, sodium sulfite 1%, methanol 10%, and the balance is deionized water.

[0045] The preparation method of the anti-sticking pot agent: first add 20% water to the reaction kettle, start stirring, the stirring speed is 2500r / min, and the stirring time is 25min; the temperature is raised to 70°C, and nitrogen is continuously purged. Then add 5% tetrahydroxynaphthalene and 1% sodium hydroxide into the kettle and stir until all are dissolved. Continue to mix 5% o-hydroxybenzaldehyde, 2% sodium formaldehyde sulfoxylate and 10% deionized water to prepare and dissolve, then add dropwise to the reaction kettle, and keep warm at 70°C for 3h. The temperature of the reaction kettle was raised to 90°C, and 2% of 1-naphthol-4-carboxylic acid, 1% of sodiu...

Embodiment 2

[0047] The composition and ratio of anti-sticking agent are: 1% o-hydroxybenzaldehyde, 6% 1, 4, 5, 8-tetrahydroxynaphthalene, 3% 1-naphthol-4-carboxylic acid, sodium formaldehyde sulfoxylate 1%, polyvinyl alcohol 3%, potassium hydroxide 2%, sodium bisulfite 1% methanol 15%, and the balance is deionized water.

[0048] The preparation method of the anti-sticking pot agent: first add 20% water to the reaction kettle, start stirring, the stirring speed is 2600r / min, and the stirring time is 15min; the temperature is raised to 70°C, and nitrogen is continuously purged. Then add 6% of 1, 4, 5, 8-tetrahydroxynaphthalene and 1% of potassium hydroxide into the kettle, and stir until completely dissolved. Continue to mix 1% o-hydroxybenzaldehyde, 1% sodium formaldehyde sulfoxylate and 10% deionized water to prepare and dissolve, then add dropwise to the reaction kettle, and keep warm at 70°C for 2.5h. The temperature of the reactor was raised to 90°C, 3% of 1-naphthol-4-carboxylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com