A coating for high-sulfur-resistant protein beverage cans and preparation method thereof

A technology of protein drink and high sulfur resistance, applied in the field of coatings, can solve problems such as aging, yellowing, and unstable anti-sulfur performance, and achieve the effects of good performance stability, short production cycle and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

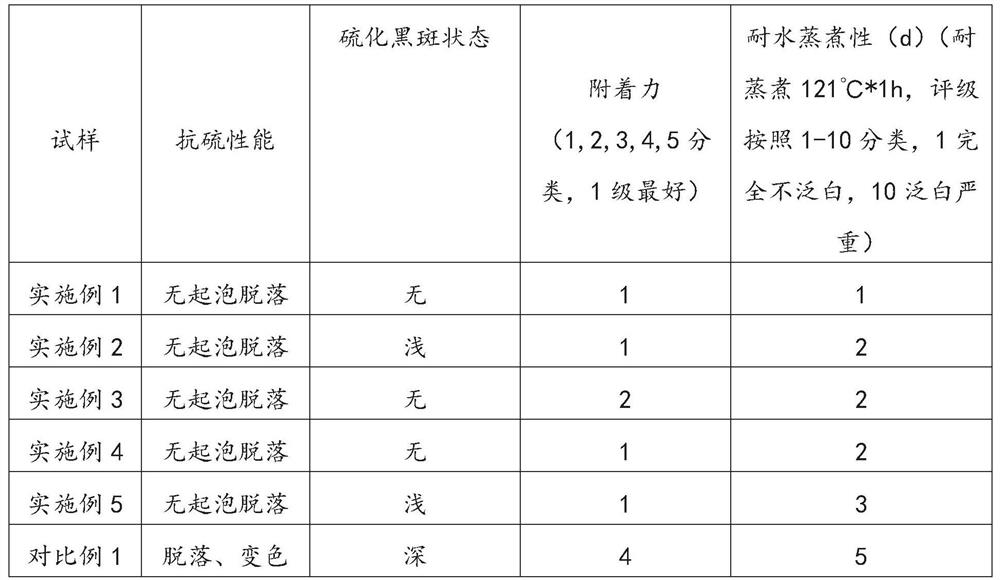

Examples

preparation example Construction

[0021] Another object of the present invention is to provide a method for preparing a high-sulfur-resistant protein beverage can coating, comprising the following steps: mixing the components by weight, and performing anchor stirring at 60-80 rpm for 30-50 Minutes, dispersed and filtered, then packaged, the grade of the filter element ≤ 5 μm, to obtain a coating for beverage cans with high anti-sulfur protein.

[0022] Due to the application of the above-mentioned technical solutions, the present invention has the following advantages compared with the prior art: the present invention provides a coating for a high-sulfur-resistant protein beverage can, which mainly uses a conventional high-equivalent epoxy resin, combined with a highly flexible phenolic resin, and then Supplemented with wax and a small amount of additives, it can significantly improve the sulfur resistance of the inner coating, especially the sulfur resistance of the processed part, and prevent the formation of...

Embodiment 1

[0025] Embodiment 1 provides a kind of coating for high anti-sulfur protein beverage can, it is characterized in that, comprises following each component by weight: 20 parts of bisphenol A type epoxy resins, 2 parts of tert-butylphenol phenolic resins, pigment phenolic resin 1 part, 10 parts of xylene, 2 parts of n-butanol, 6 parts of propylene glycol methyl ether acetate, 5 parts of ethylene glycol monobutyl ether, 10 parts of S100# aromatic hydrocarbon, 0.05 part of wax, and 0.01 part of leveling agent.

[0026] Described bisphenol A epoxy resin is the bisphenol A epoxy resin that the model that Shell Company produces is the bisphenol A epoxy resin of Epon1007.

[0027] The phenolic pigment includes the following components in parts by weight: 13 parts of QX-60 titanium complex, 20 parts of natural rosin, and 30 parts of p-tert-butylphenol novolac resin.

[0028] The wax comprises the following raw materials in parts by weight: 3 parts of polyethylene wax micropowder, 15 par...

Embodiment 2

[0032] Embodiment 2 provides a coating for high sulfur-resistant protein beverage cans, its formula and preparation method are basically the same as in Embodiment 1, the difference is that it includes the following components in parts by weight: bisphenol A epoxy resin 23 3 parts, 3 parts of tert-butylphenol phenolic resin, 1.5 parts of pigment phenolic resin, 15 parts of xylene, 4 parts of n-butanol, 8 parts of propylene glycol methyl ether acetate, 7 parts of ethylene glycol monobutyl ether, 13 parts of S100# aromatic hydrocarbon, wax 0.25 parts, 0.08 parts of leveling agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap