Pre-cabin type transformer substation cabin roof corrosion prevention and water collection and drainage method

A technology for substations and cabins, applied in roof drainage, roofs, substation rooms, etc., can solve problems such as easy snow accumulation, easy freezing of electrical equipment, corrosion of prefabricated warehouse roofs, etc., to prevent corrosion, prevent unstable work, Guarantee the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

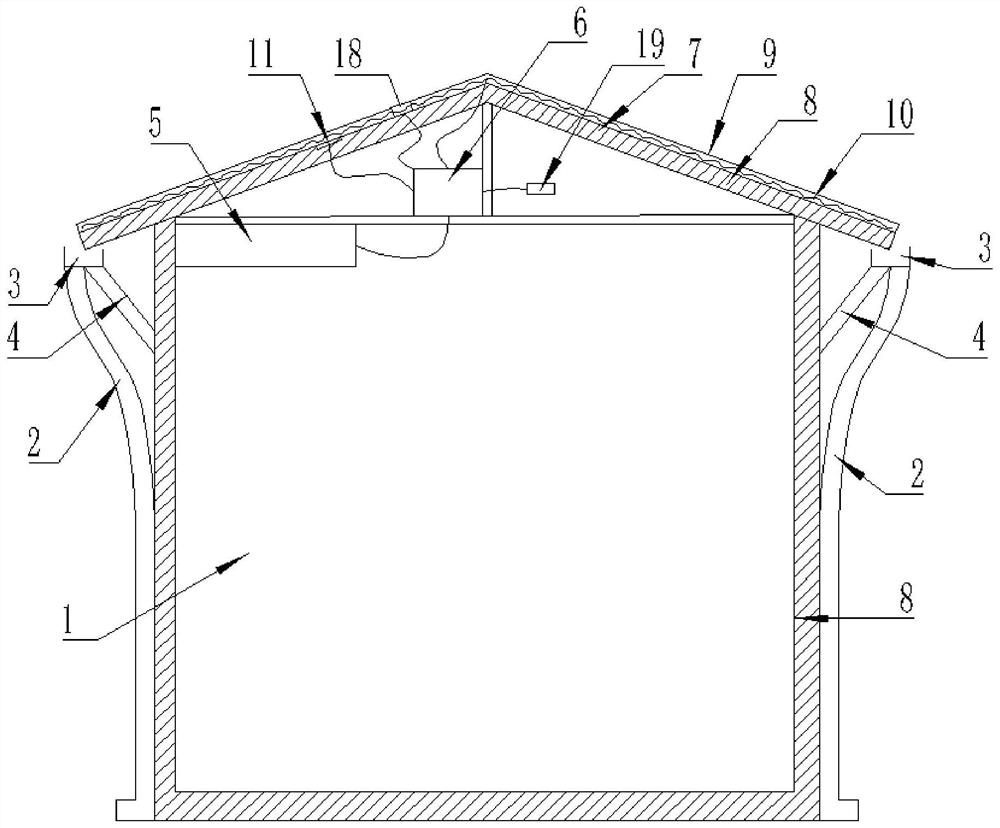

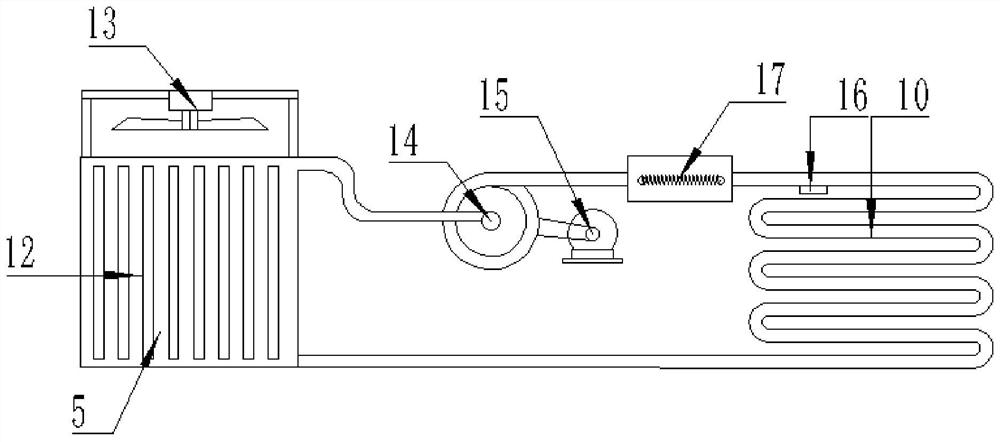

[0032] as attached figure 1 and figure 2 As shown, the present invention discloses a preferred embodiment of an anti-corrosion device for the cabin roof of a prefabricated substation, including a prefabricated cabin substation 1, the top of the prefabricated cabin substation 1 is provided with a roof 7, and the lowermost part of the roof 7 is A water diversion tank 3 is arranged under the eaves, and the drainage pipe 2 is connected to it. A water diversion tank support frame 4 is arranged on the upper side of the prefabricated cabin substation 1, and the water diversion tank support frame 4 is used to fix and support the water diversion tank 3 . The roof 7 includes an insulating layer 8 on which a load-bearing layer is arranged, a roof surface 9 is arranged above the load-bearing layer, and a heat release pipe 10 is arranged on the roof surface 9 and the load-bearing layer.

[0033] The roof 7 is provided with a heating and snow removal device, and the heating and snow remo...

Embodiment 2

[0043] A control method for an anti-corrosion device for a cabin roof of a pre-cabined substation, comprising the following steps:

[0044] S1. Outdoor temperature sensor 18, indoor temperature sensor 19, pipeline temperature sensor 16 send the detected temperature to the signal processing module in real time, and the signal processing module samples and traverses time-sharing detection of outdoor temperature sensor 18, indoor temperature sensor 19, The pipeline temperature sensor 16 transmits the data and converts it into a digital signal and sends it to the central processing unit; the pressure sensor 11 sends the detected pressure to the signal processing module in real time, and the signal processing module samples the pressure sensor 11 in time data and convert it into a digital signal and send it to the central processing unit;

[0045] S2. When the outdoor temperature is lower than the indoor temperature and the indoor temperature is higher than the maximum threshold T1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com