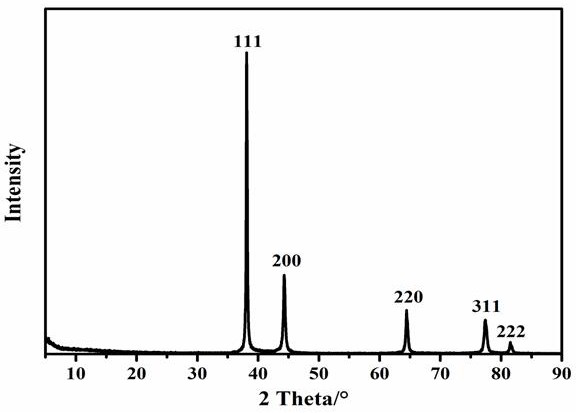

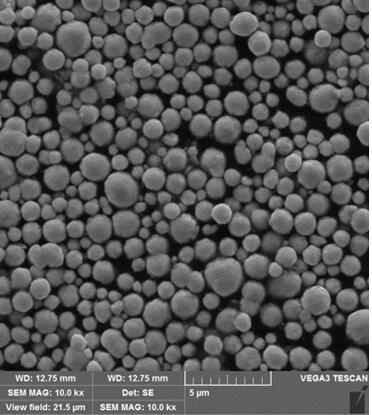

A method for preparing silver powder by space confinement method

A technology of silver powder and confinement, which is applied in the field of metal powder material preparation, can solve the problems of complex process flow and unsuitability for large-scale production, and achieve the effects of convenient operation process, considerable enterprise benefit index and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Dissolve 600g silver nitrate white crystals with 1962mL deionized water to obtain a silver nitrate aqueous solution with a concentration of 1.8 mol / L, add 30g Tween-80 to it, stir and dissolve to obtain a uniform silver nitrate dispersion, and maintain the solution temperature at 30±2°C.

[0031] Step 2: Weigh 300g of ascorbic acid and 90g of sodium ascorbate and dissolve them in 2214mL of deionized water, stir and dissolve to obtain a reducing agent aqueous solution with a concentration of 1.0 mol / L, and maintain the solution temperature at 30±2°C; under an ultrasonic bath, dissolve the reducing agent The aqueous solution is transferred from the screw reactor (such as figure 1 As shown) the middle inlet of the top is added, the flow rate is controlled at 40mL / min, and after flowing through 1 / 5 of the height of the glass tube, the silver nitrate dispersion is added from the top side inlet of the spiral reactor, and the flow rate is controlled at 30mL / min. The s...

Embodiment 2

[0035] Step 1: Dissolve 600g of silver nitrate white crystals with 1962mL of deionized water to obtain a silver nitrate aqueous solution with a concentration of 1.8 mol / L, add 60g of polyvinylpyrrolidone-K30 to it, stir and dissolve to obtain a uniform silver nitrate dispersion, and maintain the solution temperature at 30±2°C.

[0036]Step 2: Dissolve 300g of ascorbic acid and 30g of sodium borohydride in 2214mL of deionized water, stir and dissolve to obtain a reducing agent aqueous solution with a concentration of 1.0 mol / L, and maintain the solution temperature at 30±2°C; The aqueous solution of silver nitrate is added from the middle inlet of the top of the spiral reactor through a circulating pump, and the flow rate is controlled at 30mL / min. After flowing through 1 / 2 of the height of the glass tube, the silver nitrate dispersion is added from the top side of the spiral reactor. The flow rate is controlled at 20mL / min, so that silver nitrate and reducing agent undergo a r...

Embodiment 3

[0040] Step 1: Dissolve 600g silver nitrate white crystals with 1962mL deionized water to obtain a silver nitrate aqueous solution with a concentration of 1.8 mol / L, add 30g Tween-80 to it, stir and dissolve to obtain a uniform silver nitrate dispersion, and maintain the solution temperature at 30±2°C.

[0041] Step 2: Dissolve 300g of ascorbic acid and 90g of phosphorous acid in 2214mL of deionized water, stir and dissolve to obtain a reducing agent aqueous solution, the concentration of which is 1.0 mol / L, and maintain the solution temperature at 30±2°C; The aqueous solution is added from the middle inlet on the top of the spiral reactor through a circulating pump, and the flow rate is controlled at 40mL / min. After flowing through 1 / 5 of the height of the glass tube, the silver nitrate dispersion is added from the top side inlet of the spiral reactor, and the flow rate is Controlled at 30mL / min, the silver nitrate and the reducing agent undergo a reduction reaction in the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com