Frequency-adjustable intelligent wave-absorbing metamaterial and preparation method thereof

A metamaterial and adjustable technology, applied in chemical instruments and methods, flat products, other chemical processes, etc., can solve problems such as limiting the use range of microwave-absorbing metamaterials, and achieve improved corrosion problems, durability, and microwave-absorbing performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

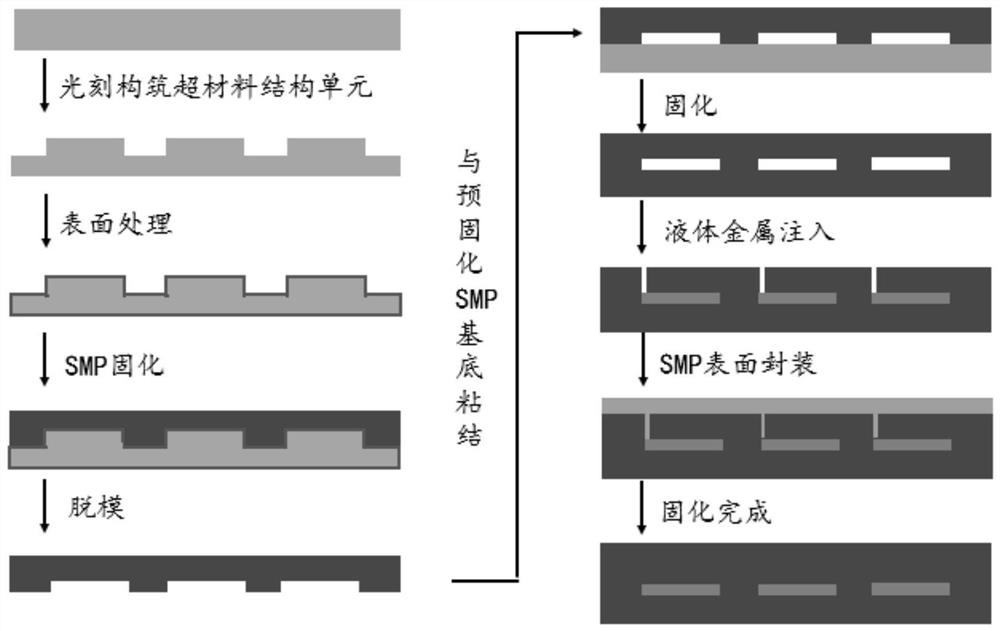

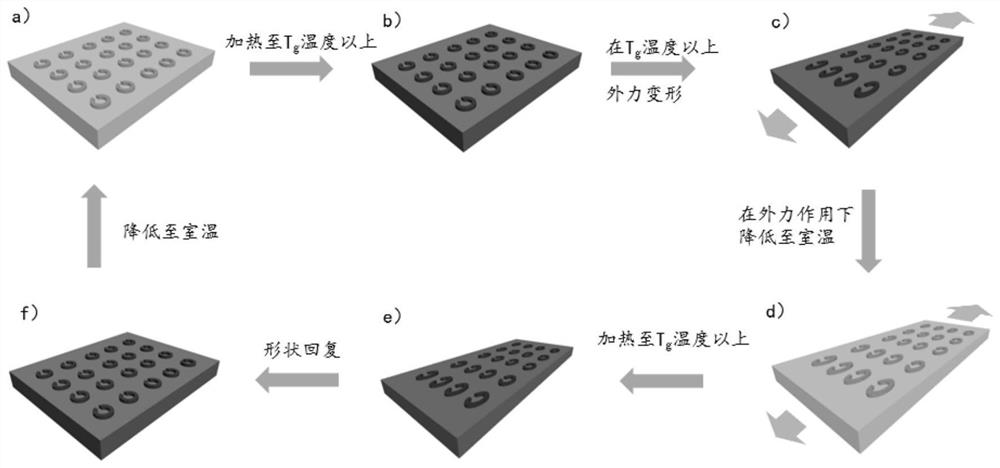

[0034] In the present invention, the preparation method of the intelligent wave-absorbing metamaterial with adjustable frequency includes the following steps:

[0035](1) Construct the designed metamaterial pattern on the surface of the silicon plate by photolithography to obtain the metamaterial structural silicon plate;

[0036] (2) Carrying out surface fluorosilane modification (surface treatment) to the surface of the metamaterial structure silicon plate obtained in step (1), to obtain a metamaterial structure silicon plate after fluorosilane modification;

[0037] (3) resin matrix, toughening agent and curing agent are mixed uniformly, obtain SMP (shape memory) resin matrix prepolymer; Described resin matrix is selected from epoxy resin, polyurethane resin, polystyrene resin and polynorbornene One or more of the resins; in the present invention, the SMP resin matrix refers to the shape memory resin matrix, and the SMP resin matrix prepolymer refers to the shape memory r...

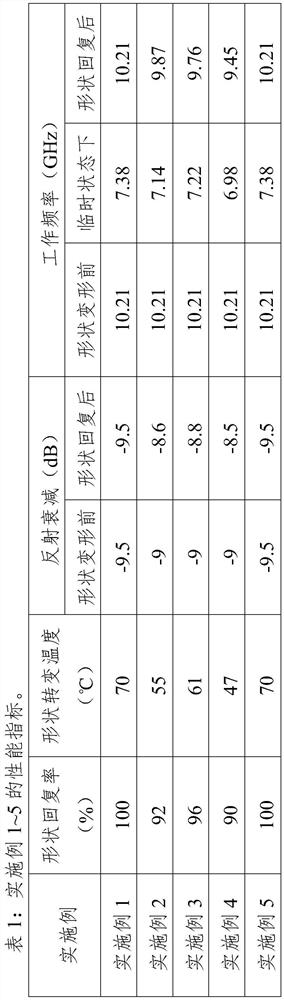

Embodiment 1

[0061] ①Use the designed metamaterial pattern to construct the metamaterial unit on the surface of the silicon plate by photolithography to obtain the metamaterial structure silicon plate. The designed metamaterial structural unit is a split resonant ring, and the specific parameters of the resonant ring are: the inner diameter of the split ring is 1.5 mm, the outer diameter is 2.0 mm, the thickness is 0.5 mm, and the opening distance is 1.0 mm.

[0062] ②The surface of the prepared silicon plate with metamaterial structure is modified with fluorosilane: the silicon plate with metamaterial structure is firstly placed in H 2 SO 4 (98%) and H 2 o 2 (30%) in a mixed solution with a mixing volume of V / V=3:1, wash at 80°C for 1h, rinse the surface with deionized water, and dry it with nitrogen gas for later use; bombard the surface of the cleaned silicon plate with oxygen plasma for 5min Finally, fluorosilane was deposited on the silicon surface (the surface of the metamaterial ...

Embodiment 2

[0071] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0072] In step ③, according to the mass ratio of 1:0.33, respectively weigh the corresponding mass of epoxy resin (E-51) and n-octylamine, put them into an oven and heat to 80°C, and keep at constant temperature for 20min. Then epoxy resin is mixed with n-octylamine, after stirring evenly, m-xylylenediamine is added, and the mass ratio of m-xylylenediamine and epoxy resin is 0.01:1, and it is stirred evenly again to obtain SMP epoxy resin prepolymer .

[0073] The same method as in Example 1 was used to test the performance of the frequency-adjustable smart absorbing metamaterial prepared in this example, and the measured reflectivity at 10.21 GHz is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com