A kind of preparation method of zinc oxide nanowire pattern

A technology of zinc oxide nanowires and patterns, applied in the field of material chemistry, can solve the problems of failing to give full play to the photoelectric performance of zinc oxide nanomaterials, not being able to prepare zinc oxide nanowire arrays, and having no preparation process, so as to avoid large-scale and high-priced The use of equipment, high one-dimensional vertical orientation, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

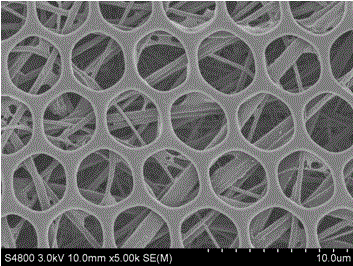

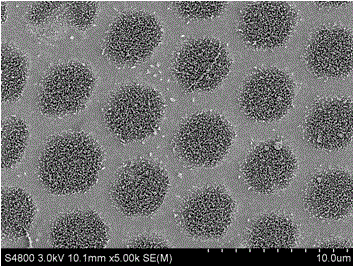

[0021] will PS- b -PDMAEMA was dissolved in carbon disulfide to obtain a homogeneous PS of 1 mg / mL- b -PDMAEMA solution, PS- b -The molar percentage of styrene units in PDMAEMA is 90%, and 0.1 mL of PS- b - Spread the PDMAEMA solution evenly on the ice surface, quickly place it in an environment with a relative humidity of 80%, and take it out after the solvent evaporates to obtain a through-type PS- b - PDMAEMA honeycomb-shaped ordered porous membrane with a pore size of 3.9 μm; the silicon wafers were placed in acetone solution and deionized water for 30 minutes, and then dried with nitrogen gas, and the above silicon wafers were sputtered by radio frequency magnetron sputtering technology. A zinc oxide seed layer is formed on the surface, the specific conditions are: growth temperature 350°C, sputtering pressure 1.0 Pa, gas atmosphere 80 sccm Ar : 5 sccm O 2 , sputtering time 1 hour, sputtering power 100 W. Covering the through-type PS- b -PDMAEMA honeycomb ordered por...

Embodiment 2

[0023] will PS- b -PHEMA was dissolved in carbon disulfide to make 1 mg / mL homogeneous PS- b -PHEMA solution, PS- b -The molar percentage of styrene units in PHEMA is 99%, and 0.1 mL of PS- b -The PHEMA solution was evenly spread on the ice surface, quickly put it in an environment with a relative humidity of 75%, and took it out after the solvent evaporated to obtain a through-type PS- b -PHEMA honeycomb-shaped ordered porous membrane with a pore size of 2 μm; the glass was placed in acetone solution and deionized water for 30 minutes, ultrasonically cleaned for 30 minutes, dried with nitrogen, and then radio frequency magnetron sputtering technology was used to generate Zinc oxide seed layer, the specific conditions are: growth temperature 350°C, sputtering pressure 1.0 Pa, gas atmosphere 80 sccm Ar : 5 sccm O 2 , sputtering time 1 hour, sputtering power 100 W. On the above glass surface covered through-type PS- b -PHEMA honeycomb ordered porous membrane as a template, ...

Embodiment 3

[0025] will PS- b -PAA was dissolved in dichloromethane to prepare 5 mg / mL homogeneous PS- b -PAA solution, PS- b -The molar percentage of styrene units in PAA is 95%, and 0.1 mL of PS- b -PAA solution was evenly spread on the ice surface, quickly placed in an environment with a relative humidity of 90%, and taken out after the solvent evaporated to obtain a through-type PS- b -PAA honeycomb-shaped ordered porous membrane with a pore size of 3 μm; the gold flakes were placed in acetone solution and deionized water for 30 minutes and ultrasonically cleaned for 30 minutes. A zinc oxide seed layer is formed on the surface, the specific conditions are: growth temperature 350°C, sputtering pressure 1.0 Pa, gas atmosphere 80 sccm Ar : 5 sccm O 2 , sputtering time 1 hour, sputtering power 100 W. Cover the through-type PS- b -PAA honeycomb ordered porous membrane was used as a template, and heat-treated at 75°C for 1 hour; the prepared gold flakes were immersed in an aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com