Liquid metal driving device based on piezoelectric film, control method and manufacturing method

A technology of liquid metal and driving device, which is applied to machines/engines, liquid variable capacity machines, pumps with flexible working elements, etc. It is difficult to realize the problems of miniaturization and other problems, so as to achieve the effect of dynamic controllable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

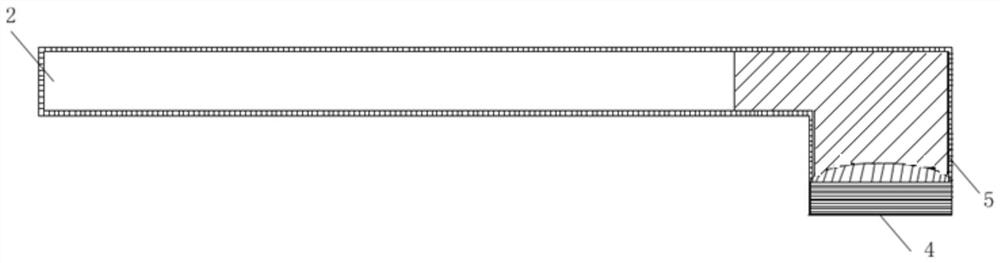

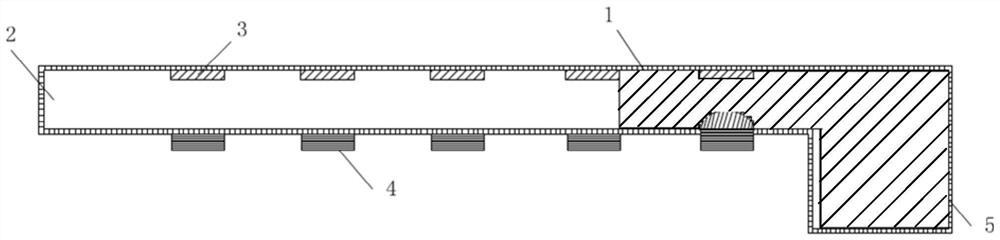

[0026] The present invention provides a liquid metal driving device based on a piezoelectric film, including a base and a cover plate, a flexible microchannel structure 2 is formed on the base, and a liquid metal capable of accommodating liquid metal 1 is formed at one end of the flexible microchannel structure 2 The liquid reservoir 5 is integrated with a thin film structure on the flexible microchannel structure 2, wherein the thin film structure is displaced and deformed under the control of voltage, and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com