Device and process for preparing hydrogen for fuel cell by using synthetic ammonia purge gas

A technology for synthesizing ammonia purge gas and fuel cell, which is applied in the direction of using solid contact hydrogen separation, hydrogen separation, diffusive hydrogen separation, etc., can solve the problems of many gas impurities, difficult removal and purification, etc., to improve the purity and achieve high purity , improve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

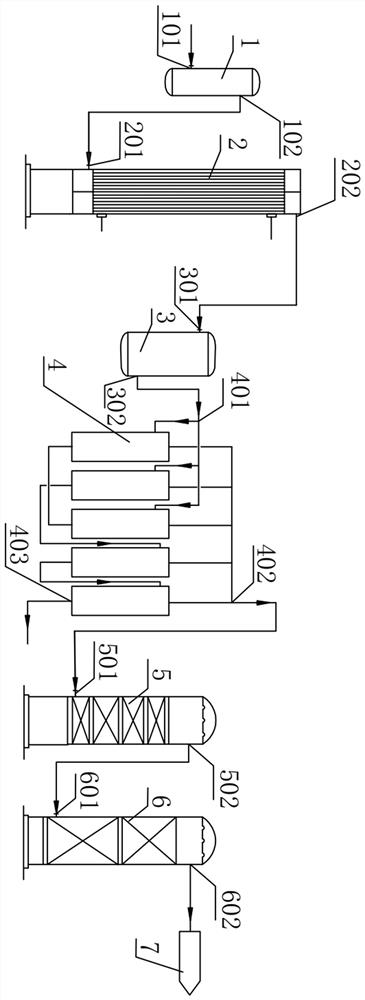

[0028] Such as figure 1 As shown, the present invention discloses a device for preparing hydrogen gas for fuel cells by using the degassing of synthetic ammonia. The upper part of the buffer tank 1 is provided with a pressure measuring instrument, and the lower part of the buffer tank 1 is provided with a nitrogen purge replacement interface. The material outlet 102 of the buffer tank is connected to the material inlet 201 of the washing tower. The washing tower 2 is equipped with auxiliary equipment such as a soft water tank, water, and washing water recovery devices, and has corresponding pipelines connected to each other to ensure sufficient water during the washing process and subsequent treatment of washing water. The material outlet 202 of the washing tower is connected to the material inlet 301 of the dryer. The dryer 3 is an automatic cycle regeneration adsorption dryer, which is mainly composed of an adsorption tower, a condenser, a gas-water separator, a forced circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com