Acrylate grouting material as well as preparation method and application thereof

A technology of grouting material and acrylate, which is applied in the field of acrylate grouting material and its preparation, which can solve the problems of acrylate gels such as easy water loss, reduced elasticity, and insufficient strength, and achieve rapid water blocking, fast crosslinking speed, The effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

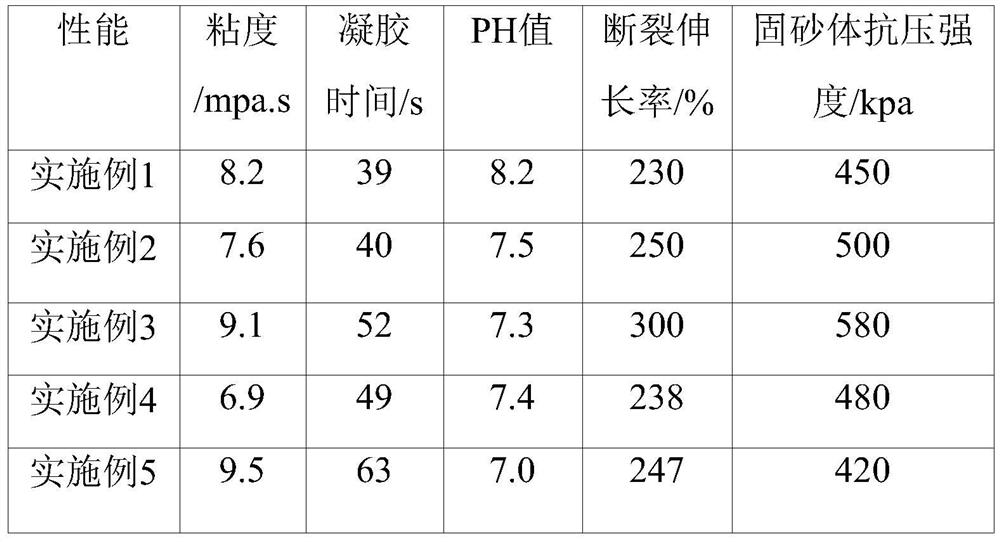

Embodiment 1

[0031] An acrylate grouting material, which is made by mixing 100 parts by mass of component A, 100 parts by mass of component B and 6 parts by mass of accelerator; wherein component A is made of the following raw materials in parts by mass : 21 parts of acrylic acid, 3 parts of light calcium carbonate, 1 part of sodium bicarbonate, 7 parts of nano-magnesium hydroxide, 65 parts of distilled water, 3 parts of self-made crosslinking agent; B component is made of the following raw materials in parts by mass Ingredients: 2 parts of sodium persulfate, 98 parts of distilled water. The performance index of the acrylate grouting material obtained in this embodiment is shown in Table 1.

Embodiment 2

[0033] An acrylate grouting material, which is made by mixing 100 parts by mass of component A, 100 parts by mass of component B and 6 parts by mass of accelerator; wherein component A is made of the following raw materials in parts by mass : 25 parts of acrylic acid, 3 parts of light calcium carbonate, 2 parts of sodium bicarbonate, 5 parts of nano-magnesium hydroxide, 63 parts of distilled water, 2 parts of self-made crosslinking agent; B component is made of the following raw materials in parts by mass Ingredients: 3 parts of sodium persulfate, 97 parts of distilled water. The performance index of the acrylate grouting material obtained in this embodiment is shown in Table 1.

Embodiment 3

[0035] An acrylate grouting material, which is made by mixing 100 parts by mass of component A, 100 parts by mass of component B and 6 parts by mass of accelerator; wherein component A is made of the following raw materials in parts by mass : 28 parts of acrylic acid, 3 parts of light calcium carbonate, 3 parts of sodium bicarbonate, 8 parts of nano-magnesium hydroxide, 54 parts of distilled water, 4 parts of self-made crosslinking agent; B component is made of the following raw materials in parts by mass Ingredients: 4 parts of sodium persulfate, 96 parts of distilled water. The performance index of the acrylate grouting material obtained in this embodiment is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com