Technological method for preparing metallized hot pellets by waste heat of submerged arc furnace

A process method and submerged arc furnace technology, applied in furnaces, electric furnaces, waste heat treatment, etc., can solve the problems of complex overall process, high energy consumption, long production cycle, etc., achieve short and practical process, reduce energy consumption and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

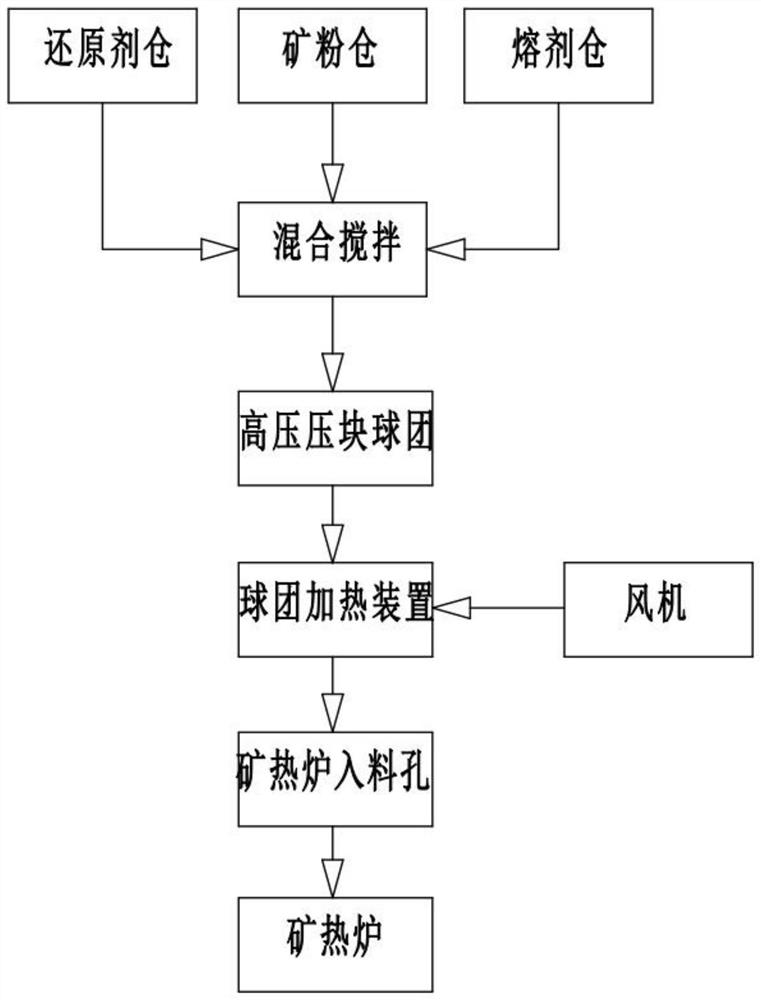

[0033]The reducing agent in the reducing agent bin, the mineral powder in the mineral powder bin and the flux in the flux bin are transported to the mixing mixer through the screw feeder. The ratio of mineral powder, reducing agent and flux is 55:25:20 , And the particle size of mineral powder, reducing agent and flux is 0.3~1.2mm;

[0034]Use a mixing mixer to mix the mineral powder, reducing agent, and flux evenly. The rotation speed of the mixing mixer is 50r / min, and the mixing time is 30min;

[0035]Introduce the mixed powder into a high-pressure ball press to form a compact, and shape it into a high-pressure briquette pellet. The spindle speed of the high-pressure ball press is 12r / min and the molding pressure is 33MPa;

[0036]The high-pressure briquette pellets are fed into the pellet heating device, and the negative pressure exhaust fan connected to the pellet heating device introduces the high temperature flue gas generated during the operation of the submerged arc furnace into the...

Embodiment 2

[0041]The reducing agent in the reducing agent bin, the mineral powder in the mineral powder bin and the flux in the flux bin are transported to the mixing mixer through the screw feeder. The ratio of mineral powder, reducing agent and flux is 60:21:19 , And the particle size of mineral powder, reducing agent and flux is 0.5~1.1mm;

[0042]Use a mixing mixer to mix the mineral powder, reducing agent, and flux evenly. The rotation speed of the mixing mixer is 60r / min, and the mixing time is 30min;

[0043]Introduce the mixed powder into a high-pressure ball press to form a compact, and shape it into a high-pressure briquette pellet. The spindle speed of the high-pressure ball press is 12r / min and the molding pressure is 35MPa;

[0044]The high-pressure briquette pellets are fed into the pellet heating device, and the negative pressure exhaust fan connected to the pellet heating device introduces the high temperature flue gas generated during the operation of the submerged arc furnace into the...

Embodiment 3

[0049]The reducing agent in the reducing agent bin, the mineral powder in the mineral powder bin and the flux in the flux bin are transported to the mixing mixer through the screw feeder. The ratio of mineral powder, reducing agent and flux is 53:21:26 , And the particle size of mineral powder, reducing agent and flux is 0.1~0.9mm;

[0050]Use a mixing mixer to mix the mineral powder, reducing agent, and flux evenly. The rotation speed of the mixing mixer is 75r / min, and the mixing time is 30min;

[0051]Introduce the mixed powder into a high-pressure ball press to form a compact, and shape it into a high-pressure briquette pellet. The spindle speed of the high-pressure ball press is 10r / min and the molding pressure is 37MPa;

[0052]The high-pressure briquette pellets are fed into the pellet heating device, and the negative pressure exhaust fan connected to the pellet heating device introduces the high-temperature flue gas generated during the operation of the submerged arc furnace into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com