Semiconductor laser chip assembly for high-speed optical signal transmission

A laser and optical signal technology, applied in semiconductor lasers, laser parts, lasers, etc., can solve the problem of insufficient modulation bandwidth to achieve high-speed optical signal transmission, and achieve the effect of ensuring large-scale production, good reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

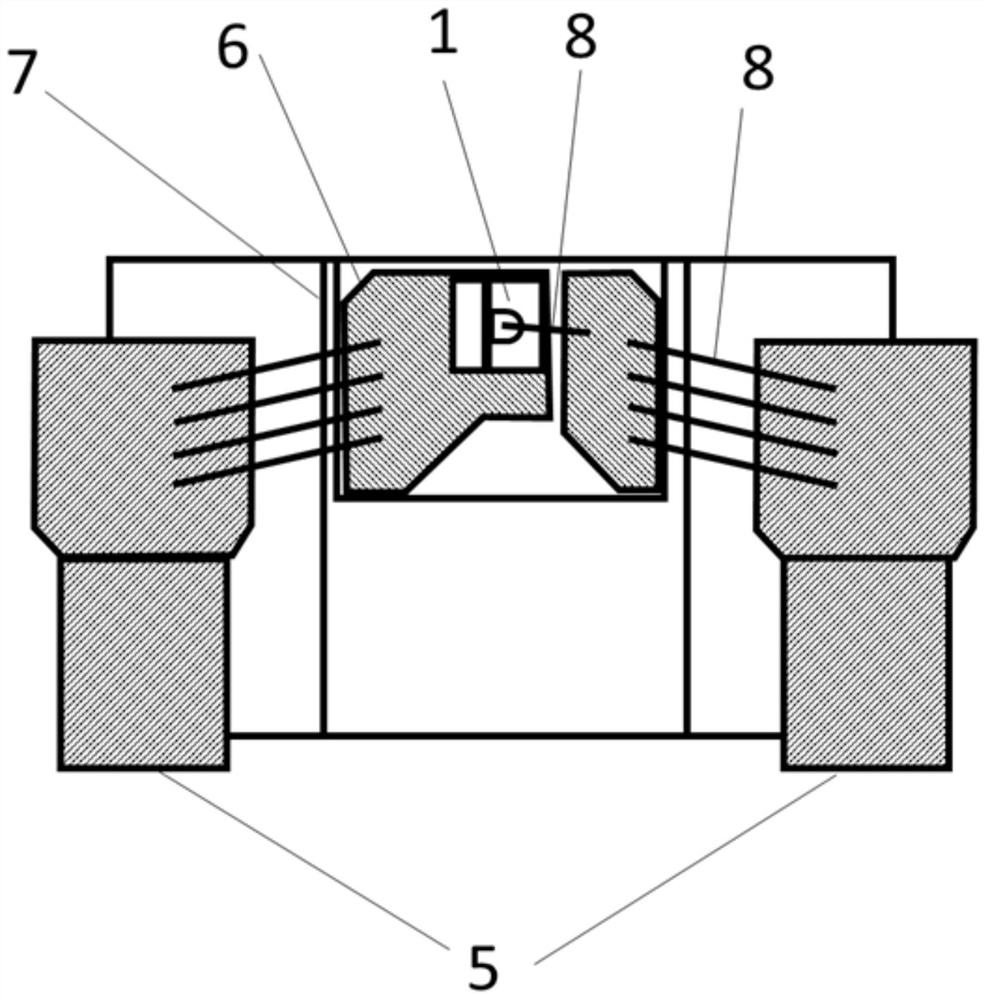

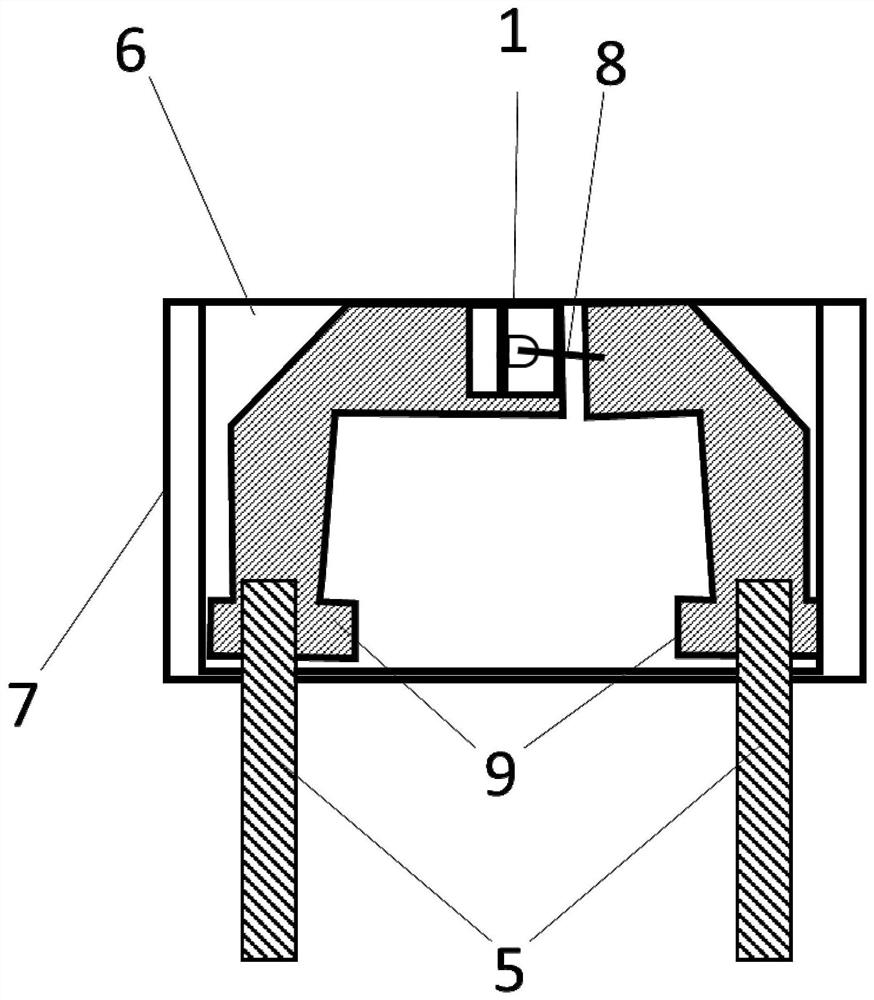

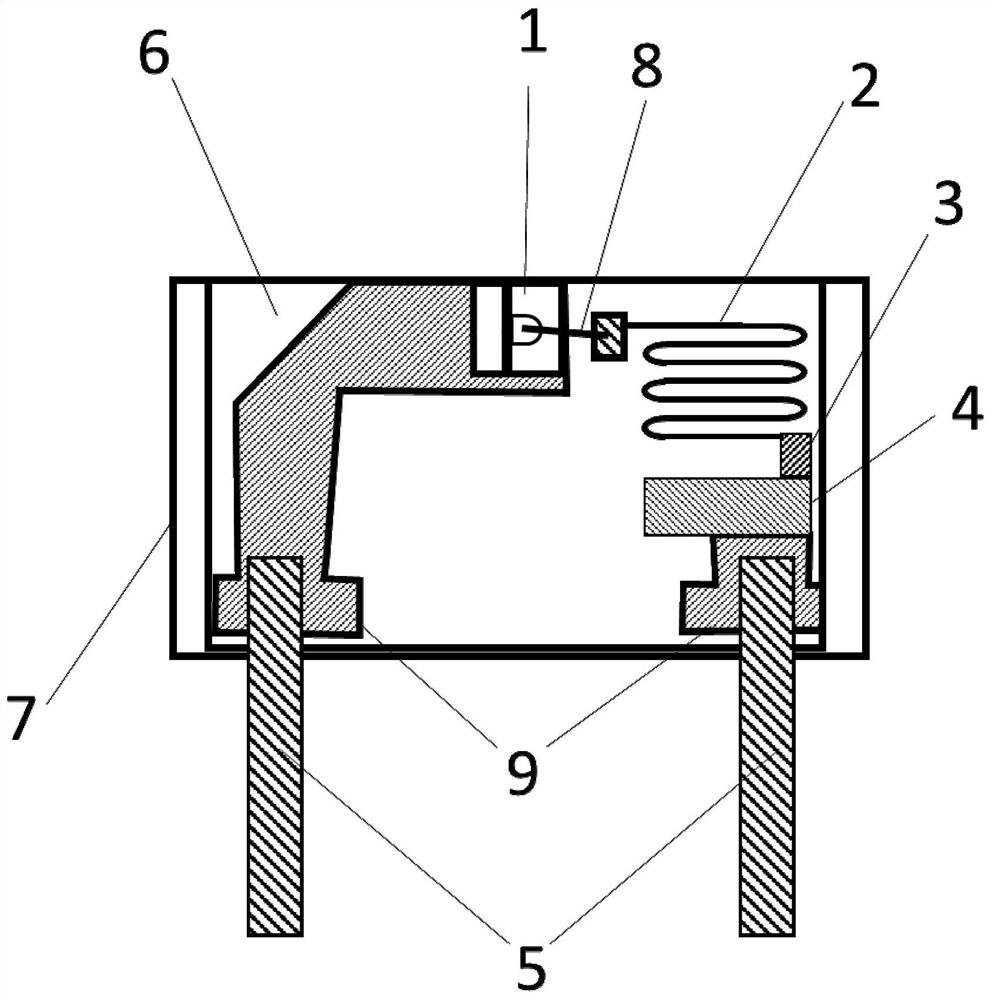

[0050] Such as image 3 As shown, the semiconductor laser chip assembly used for high-speed optical signal transmission in the present invention includes a laser chip 1, an inductor 2, a resistor 3, a capacitor 4 and at least two leads 5 connected to external drive electrical signals, and the laser chip 1 Fixedly pasted on a substrate 6, the substrate 6 is located on a heat sink base 7; the substrate 6 is provided with at least two metal thin film transmission lines 9, wherein one end of one transmission line 9 is connected to a lead wire 5, and the other end of the transmission line 9 One end is connected to the front of the capacitor 4; one end of the other transmission line 9 is connected to the other lead 5, and the other end of the transmission line 9 is connected to the cathode of the laser chip 1;

[0051] The laser chip 1 is connected to one end of the inductor 2 through a gold wire 8, the other end of the inductor 2 is connected in series with one end of the resistor ...

Embodiment 2

[0064] In Embodiment 1, the inductor 2 is made by thin-film technology, and is located on the same substrate 6 as the resistor 3 and the capacitor 4; the laser chip 1 and the inductor 2 are connected through gold wires. Since the diameter of the gold wire 8 used for chip connection is only about 25 microns, it will generate self-induced inductance, so the inductance 2 in the embodiment 1 can be replaced by a gold wire 8 to form a Figure 7 Example 2 shown;

[0065] In Embodiment 2, the inductor 2 originally located on the same substrate 6 as the resistor 3 and capacitor 4 is replaced by a certain length of gold wire 8, which not only provides the connection between the resistor 3 and the laser chip 1, but also acts as an inductor 2; compared with embodiment 1, embodiment 2 replaces inductance 2 with gold wire, not only can reduce cost, but also because the length of gold wire can be adjusted during chip packaging, the inductance value also changes accordingly, so different len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com