High-stability wet tissue packaging machine

A high-stability, wet tissue packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems that affect production efficiency, packaging bag wrinkles, loud noise, etc., and achieve improved stability, fluency, and action Good stability, good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

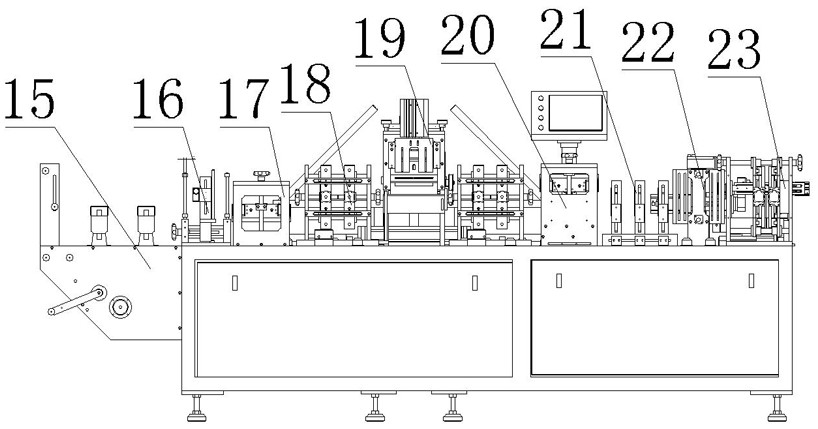

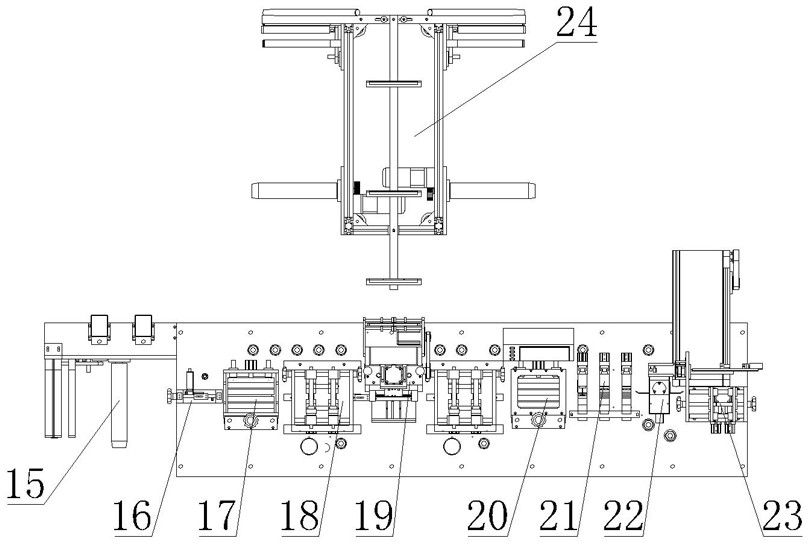

[0019]As shown in the figure, the high-stability wet tissue packaging machine disclosed by the present invention includes a packaging bag unwinding mechanism 15, a packaging bag forming mechanism 16, a packaging bag bottom sealing mechanism 17, a packaging bag vertical sealing mechanism 18, and a wet tissue packaging machine arranged in sequence. Cutting half-folding press-in mechanism 19, packaging bag mouth sealing mechanism 20, batch number embossing mechanism 21, traction mechanism 22 and punching mechanism 23, wet wipes unwinding and folding are arranged on one side of wet wipes cutting half-folding press-in mechanism 19 Mechanism 24, wherein packaging bag unwinding mechanism 15, packaging bag forming mechanism 16, packaging bag bottom sealing mechanism 17, packaging bag mouth sealing mechanism 20, batch number embossing mechanism 21, traction mechanism 22 and punching mechanism 23 are common on the market The structure belongs to the prior art, so it will not be repeated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com