Heavy metal contaminated soil curing agent and preparation method and application thereof

A technology for polluted soil and heavy metals, applied in the field of soil remediation, can solve the problems of high price of chemical remediation agents, consumption of natural resources, and general remediation effect, and achieve the effects of remediating heavy metal pollution, high unconfined compressive strength, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, steel slag and slag were mixed at a weight ratio of 40:60, acidified with phosphoric acid for 24 hours, and the amount of phosphoric acid added was 3.2% of the total weight of steel slag and slag to obtain heavy metal contaminated soil curing agent 1#.

[0030] Mix the heavy metal contaminated soil curing agent 1# with the heavy metal contaminated soil according to the mass ratio of 25:100, then add water, the mass ratio of water and heavy metal contaminated soil curing agent is 1:3, stir, natural conservation for 28 days, test the curing rate and Unconfined compressive strength.

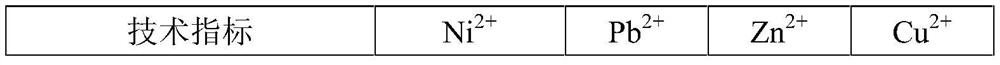

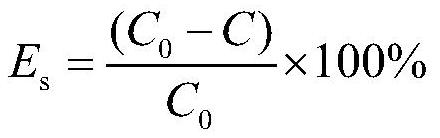

[0031] The results obtained are as follows:

[0032] technical indicators Ni 2+

Embodiment 2

[0034] In this example, steel slag and slag were mixed according to the weight ratio of 28:72, acidified with phosphoric acid for 22 hours, and the amount of phosphoric acid added was 2.2% of the total weight of steel slag and slag, and heavy metal contaminated soil curing agent 2# was obtained.

[0035] Mix the heavy metal contaminated soil curing agent 2# with the heavy metal contaminated soil according to the mass ratio of 22:100, then add water, the mass ratio of water and heavy metal contaminated soil curing agent is 1:2, stir, natural conservation for 28 days, test the curing rate and Unconfined compressive strength.

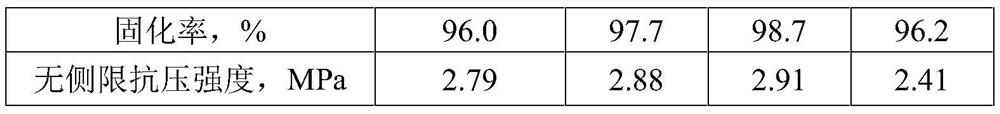

[0036] The results obtained are as follows:

[0037]

[0038]

Embodiment 3

[0040] In this example, steel slag and slag were mixed according to the weight ratio of 72:28, acidified with phosphoric acid for 26 hours, and the amount of phosphoric acid added was 4.8% of the total weight of steel slag and slag, and heavy metal contaminated soil solidification agent 3# was obtained.

[0041] Mix the heavy metal contaminated soil curing agent 3# with the heavy metal contaminated soil according to the mass ratio of 20:100, then add water, the mass ratio of water and heavy metal contaminated soil curing agent is 1:4, stir, natural conservation for 28 days, test the curing rate and Unconfined compressive strength.

[0042] The results obtained are as follows:

[0043] technical indicators Ni 2+

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap