Preparation method of surface ZnO super-hydrophobic Cu-Be alloy suitable for aviation sensor

A sensor and super-hydrophobic technology, applied in the field of bionic materials, can solve the problems of expensive low surface energy materials, complex preparation process, high adhesion, etc., and achieve the effect of low cost, low cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

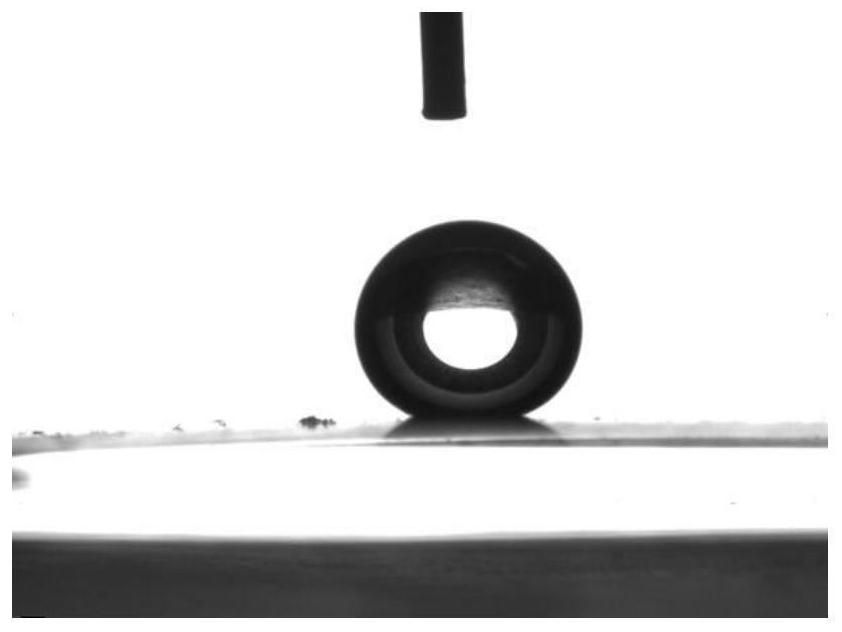

Image

Examples

Embodiment 1

[0015] A method for preparing superhydrophobic surface ZnO of a Cu-Be alloy suitable for aeronautical sensors, the specific steps are as follows:

[0016] 1. Grind the Cu-Be alloy sample with 1000 mesh sandpaper, ultrasonically clean the polished Cu-Be alloy and dry it;

[0017] Two, then the Cu-Be alloy sheet is connected to the cathode, and the carbon sheet is connected to the anode, and put into the Zn(NO3) solution prepared with 50mmol / L for water bath heating, and the water bath temperature is 60°C;

[0018] 3. Electrodeposition is then carried out under a 1.5V regulated power supply, and the electrodeposition time is 20 minutes, and dried after the deposition time is over;

[0019] 4. Then immerse the dried Cu-Be alloy sample in an organic stearic acid solution with a concentration of 5g / L for 10-25min. Allow to dry when finished for a superhydrophobic surface.

[0020] In this implementation case, the contact angle of the ZnO superhydrophobic surface of the Cu-Be allo...

Embodiment 2

[0022] A method for preparing superhydrophobic surface ZnO of a Cu-Be alloy suitable for aeronautical sensors, the specific steps are as follows:

[0023] 1. Grind the Cu-Be alloy sample with 1000 mesh sandpaper, ultrasonically clean the polished Cu-Be alloy and dry it;

[0024] Two, then the Cu-Be alloy sheet is connected to the cathode, and the carbon sheet is connected to the anode, and put into the Zn(NO3) solution prepared with 50mmol / L for water bath heating, and the water bath temperature is 60°C;

[0025] 3. Electrodeposition is then carried out under a 1.5V regulated power supply, and the electrodeposition time is 20 minutes, and dried after the deposition time is over;

[0026] 4. Then immerse the dried Cu-Be alloy sample in an organic stearic acid solution with a concentration of 5g / L for 15min. The organic solution can be selected from ethanol, toluene or n-dodecane. After the low surface energy modification is completed Allow to dry to obtain a superhydrophobic s...

Embodiment 3

[0029] A method for preparing superhydrophobic surface ZnO of a Cu-Be alloy suitable for aeronautical sensors, the specific steps are as follows:

[0030] 1. Grind the Cu-Be alloy sample with 1000 mesh sandpaper, ultrasonically clean the polished Cu-Be alloy and dry it;

[0031] Two, then the Cu-Be alloy sheet is connected to the cathode, and the carbon sheet is connected to the anode, and put into the Zn(NO3)2 solution prepared with 18mmol / L for water bath heating, and the water bath temperature is 60°C;

[0032] 3. Electrodeposition is then carried out under a 1.5V regulated power supply, and the electrodeposition time is 20 minutes, and dried after the deposition time is over;

[0033] 4. Then immerse the dried Cu-Be alloy sample in an organic stearic acid solution with a concentration of 5g / L for 15min. The organic solution can be selected from ethanol, toluene or n-dodecane. After the low surface energy modification is completed Allow to dry to obtain a superhydrophobic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com