External expansion type anti-air-shrinkage concrete block and preparation method thereof

A concrete block and expansion technology, applied in the field of concrete, can solve the problems of poor heat dissipation and large temperature difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

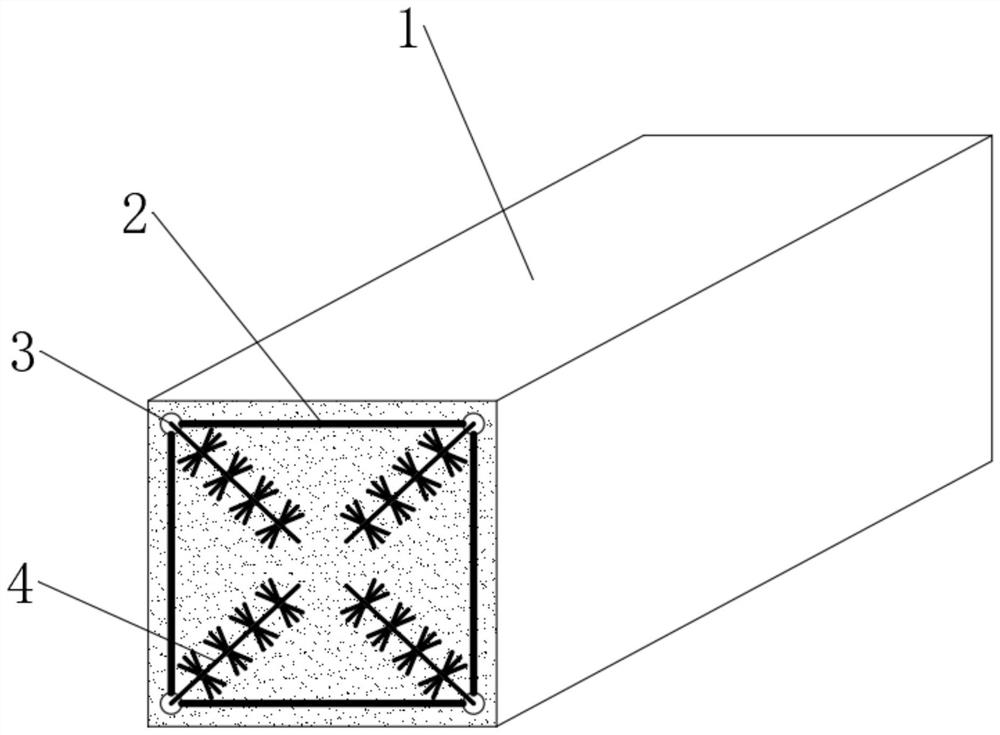

[0045] see Figure 1-2 , an external expansion type anti-drying shrinkage concrete block, comprising a concrete block body 1, the interior of the concrete block body 1 near the edge is inlaid with a steel skeleton 2, and the steel skeleton 2 is along the length direction of the concrete block body 1 A plurality of evenly distributed node reinforcement balls 3 are connected, and the node reinforcement ball 3 is connected with a heat-shrinkable centripetal rod 4 near the center of the section of the concrete block body 1;

[0046] Concrete block body 1 includes the following raw materials in parts by weight: 50 parts of Portland cement, 30 parts of superfine fly ash, 2 parts of water reducer, 1 part of activator, 10 parts of expansion agent, 1.5 parts of polypropylene fiber, 40 parts of water and 0.3 parts of polymer emulsion.

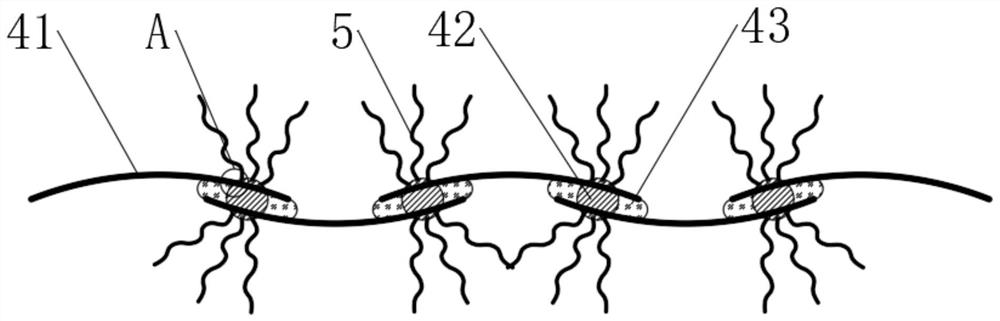

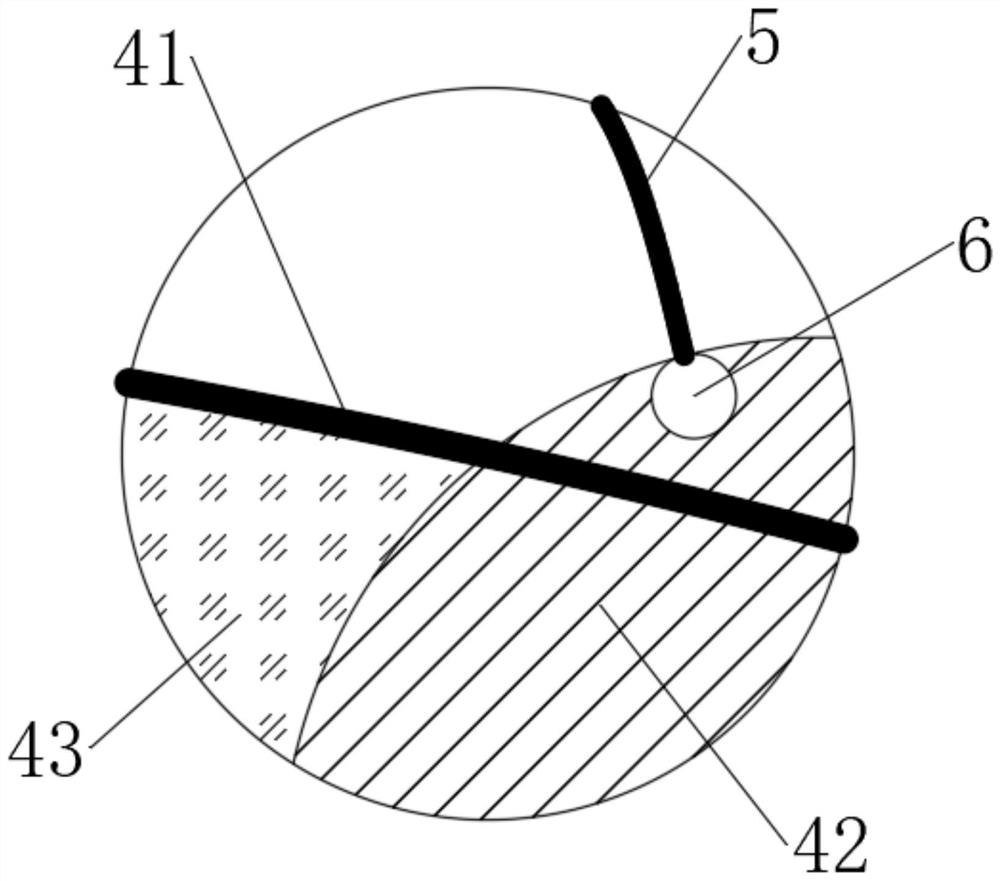

[0047] see Figure 2-4 The heat-shrinkable centripetal rod 4 includes a plurality of unit migration pieces 41 that are distributed in a staggered mann...

Embodiment 2

[0061] The concrete block body 1 includes the following raw materials in parts by weight: 60 parts of Portland cement, 40 parts of superfine fly ash, 3.5 parts of water reducer, 2.5 parts of activator, 15 parts of expansion agent, 2.2 parts of polypropylene fiber, 45 parts of water and 0.5 parts of polymer emulsion.

[0062] The rest are consistent with the embodiment.

Embodiment 3

[0064] Concrete block body 1 includes the following raw materials in parts by weight: 70 parts of Portland cement, 50 parts of superfine fly ash, 5 parts of water reducer, 4 parts of activator, 20 parts of expansion agent, 3 parts of polypropylene fiber, 50 parts of water and 0.8 parts of polymer emulsion.

[0065] The rest are consistent with the embodiment.

[0066] The present invention can realize the innovative introduction of the steel skeleton 2 as the internal skeleton of the concrete block body 1, which plays an integral role in shaping the concrete block body 1, and through the heat-shrinkable centripetal rods on the steel skeleton 2 extending toward the center 4. When the concrete block body 1 is formed, it is heated to trigger thermal shrinkage, and through the cooperation between the air-entraining base ball 6 and the air-entraining fiber tube 5, the gas is continuously released to form small and uniform pores, so that the formed The concrete block body 1 has a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com