Novel foam dust removal device for coal mining heading face

A technology of a dust removal device and a driving face, which is applied in the field of mining equipment, can solve the problems of low dust suppression efficiency of the dust removal device, poor working face environment, and high work labor intensity, and achieves low dust suppression cost, good adaptability, and work labor intensity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

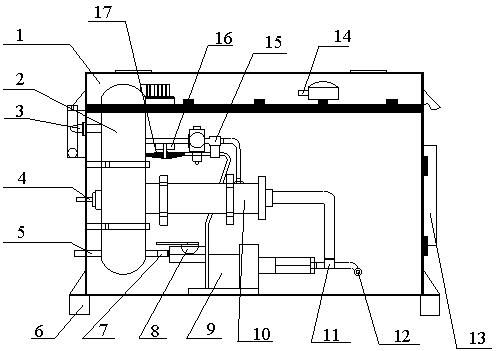

[0013] An embodiment of the present invention provides a novel foam dust removal device for a coal mining face, which will be described in detail below.

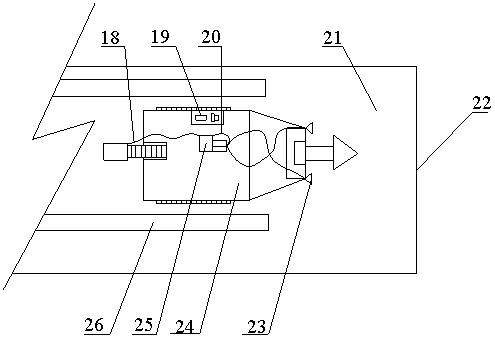

[0014] Refer to attached figure 1 , 2 , a new type of foam dust removal device for coal mining face is mainly composed of three parts: water injection system, gas transmission system and mixing section. The main device includes a liquid storage tank 2, an air inlet 3, a foam outlet 4, a water inlet 5, a gas-liquid oil suction pump 9, a foam generator 10, a material inlet 14, and a gas-water separator 15; The part 11 is connected with the gas-liquid oil suction pump 9 and the foam generator 10 to provide processing raw materials for the foam generator 10; through the ball valve 8, the amount of water entering the gas-liquid oil suction pump 9 from the water inlet 5 is controlled, thereby controlling the amount of foam produced; the air inlet 3 Connected to the needle valve 17 and connected to the gas-liquid oil suction pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com