Micro magnetic grid for manufacturing magnetic encoder by using magnetron sputtering method, and manufacturing method thereof

A magnetic encoder and magnetron sputtering technology, which is applied in sputtering coating, instruments, and conversion sensor output, etc., can solve the problems of reducing the service life of magnetic encoders, output signal defects, and unfavorable signal processing, etc., and achieve compact structure , solve the effect of low resolution and convenient machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

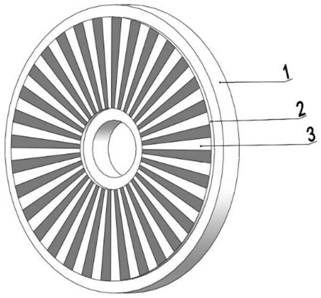

[0052] Such as figure 1Shown, a kind of miniature magnetic grid that makes magnetic encoder with magnetron sputtering method, design profile is disc shape, and the outer diameter of magnetic grid is 60mm, and internal diameter is 12mm, and the center is hole shape, and it comprises: substrate 1, Coating 2, grid 3, the shape of the substrate 1 is disc-shaped, with a round hole in the center, the material of the substrate 1 is monocrystalline silicon, and a coating is set on the ring of the outer surface of the substrate 1. Layer 2, the material of coating 2 is Co-Ni-P-La, and the material of coating 2 Co-Ni-P-La contains: 58.75% (weight percent) Co, 35.25% (weight percent) Ni, 5 % (percentage by weight) P, 1% (percentage by weight) La; a group of grids 3 are set on the coating 2, and the grids 3 are 32 pairs, the size of each magnetic grid is consistent, 360 ° circle The ring is equally divided; the number of magnetic grids determines the number of pulses output per revolution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com