Dust collection structure of glass cutting machine

A cutting machine and glass technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of poor practicability and poor adsorption effect, and achieve the effects of strong practicability, reasonable device structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

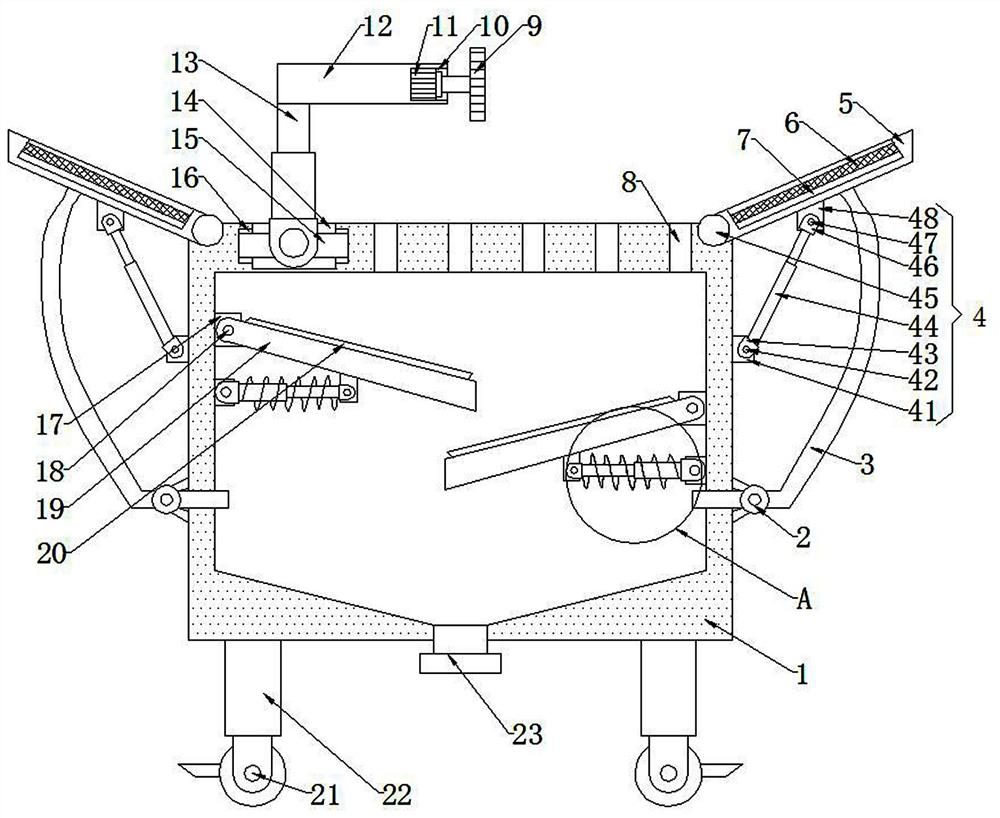

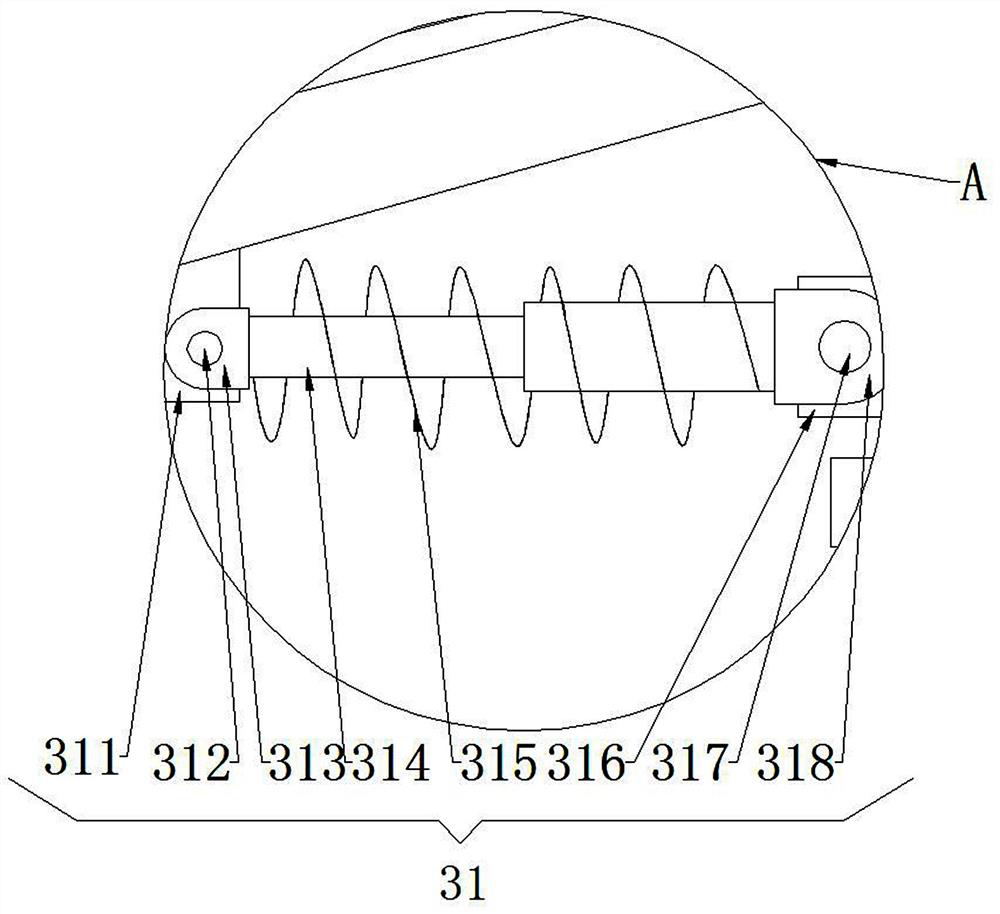

[0024] see Figure 1-4 , the present invention provides the following technical solutions: a glass cutting machine dust suction structure, including a box body 1, the front side of the box body 1 is fixedly connected with a control panel 29, the control panel 29 is electrically connected to each electrical appliance through a wire, the box body 1 The top is provided with several through holes 8, the top of the buffer plate 19 is fixedly connected with a cushion pad 20, the bottom of the box body 1 is provided with a valve 23, the bottom of the box body 1 is fixedly connected with a support leg 22, and the bottom of the support leg 22 is fixedly connected with a universal wheel 21 , The front side of the box body 1 is fixedly connected with an observation glass 30, by setting the observation glass 30, it is convenient for the user to observe the situation in the box body 1 at any time.

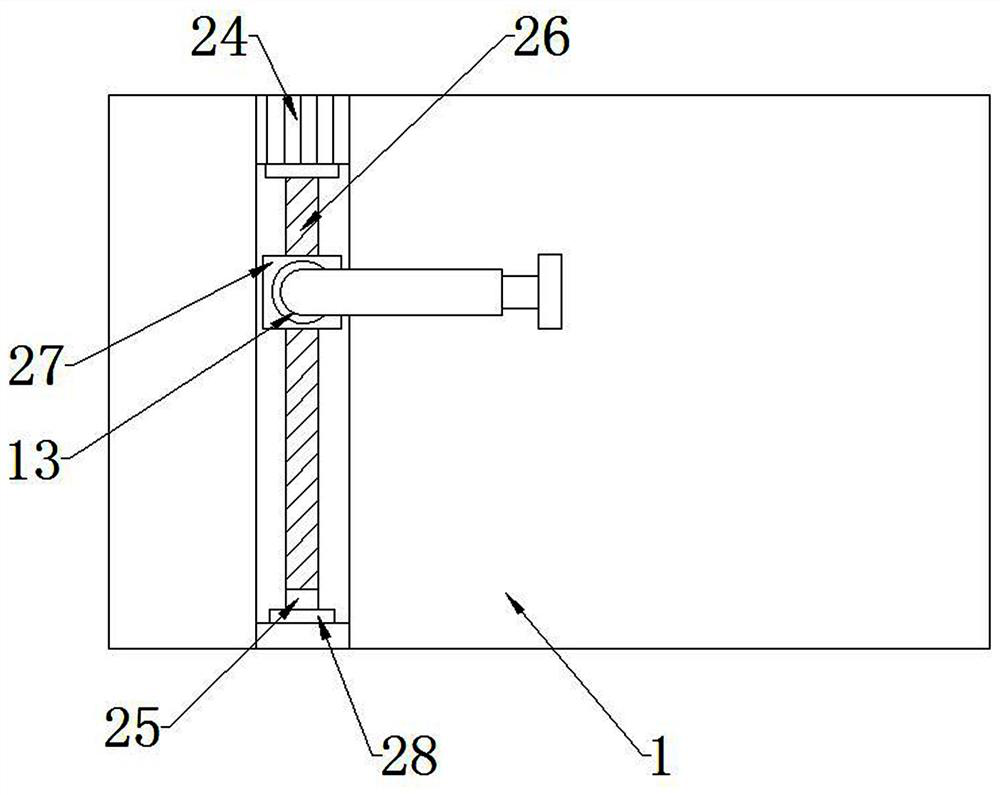

[0025] The top of the box body 1 is provided with a third groove 14, and the side of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com