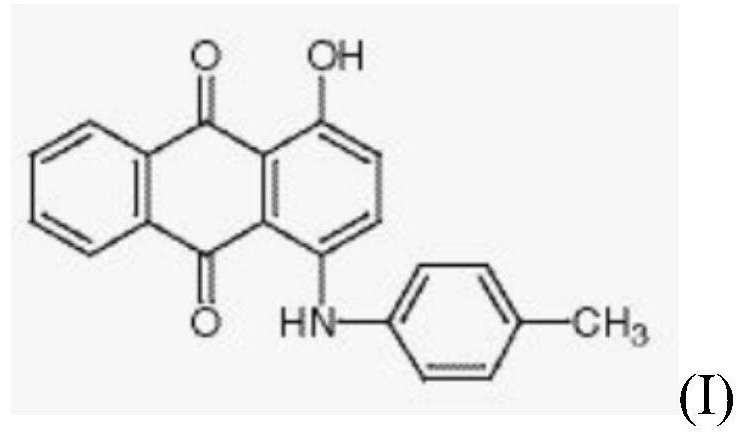

Plastic colorant purple B and preparation method thereof

A coloring agent and plastic technology, applied in the field of plastic coloring agent and its preparation, can solve the problems that the reaction is difficult to reach the end point, the reaction is not easy to complete, and the product purity is reduced, so as to achieve the effect of not easy to aggregate, fast and complete reaction, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

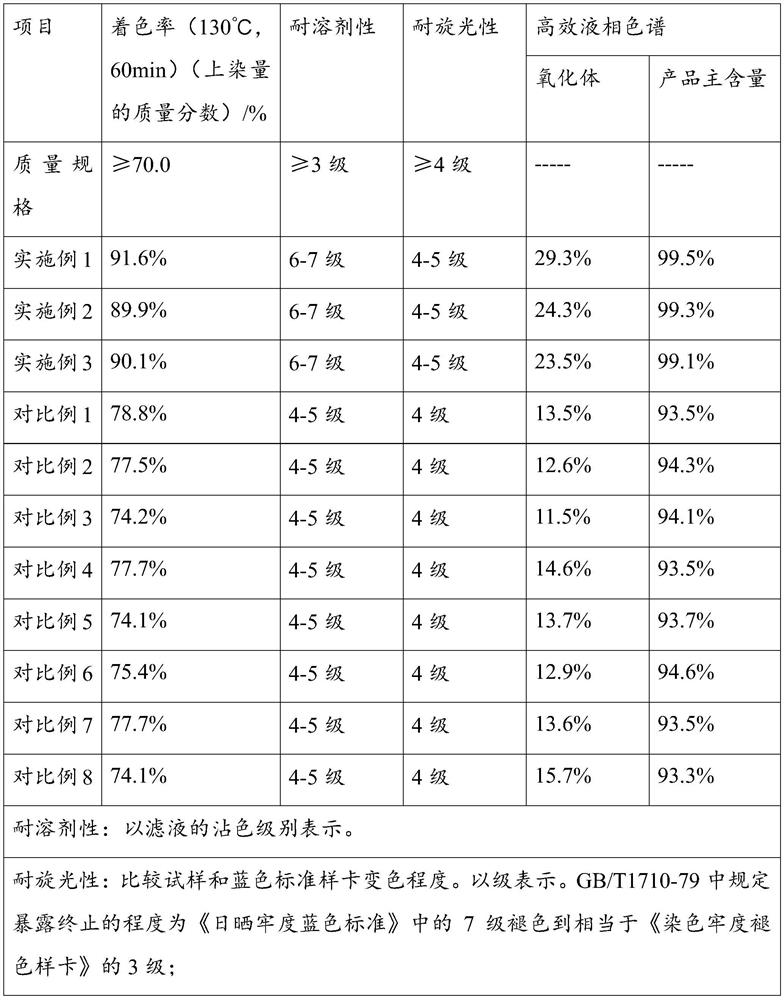

Embodiment 1

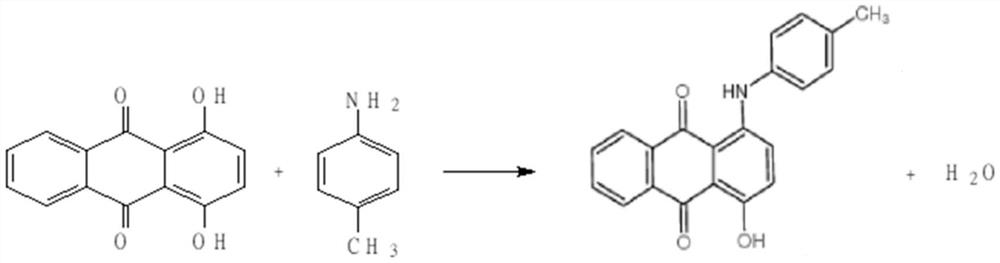

[0023] A kind of plastic coloring agent violet B, described violet B is made by violet B crude product and methanol; Wherein, described violet B crude product is made of 213 parts of 30% butanol, 240 parts of 1.4-dihydroxyanthraquinone, para Made from 107 parts of toluidine, 122 parts of 30% hydrochloric acid, 63 parts of boric acid and 80 parts of catalyst; the ratio of the methanol to the crude Violet B is 3:1 by weight; the methanol is 35% methanol.

[0024] A kind of preparation method of plastic colorant purple B, concrete steps are as follows:

[0025] (1) condensation

[0026] Inhale butanol, 1.4-dihydroxyanthraquinone, and p-toluidine into the condensation reaction kettle, stirring at a speed of 55r / min for 7 minutes, then put in hydrochloric acid, boric acid and catalyst, stirring at a speed of 85r / min, and stirring for 7 minutes. Adjust the internal positive pressure to 0.04MPa, heat up to 100-120°C, and keep warm for 5 hours (the heat preservation stage is divided ...

Embodiment 2

[0035] A kind of plastic coloring agent Violet B, described Violet B is made from Violet B crude product and methanol; Wherein, described Violet B crude product is made up of 250 parts of 25% butanol, 230 parts of 1,4-dihydroxyanthraquinone in parts by weight , 108 parts of p-toluidine, 125 parts of 25% hydrochloric acid, 60 parts of boric acid and 81 parts of catalyst are made; the ratio of the methanol and the crude product of purple B is 2:1 by weight; the methanol is 30% concentration Methanol.

[0036] A kind of preparation method of plastic colorant purple B, concrete steps are as follows:

[0037] (1) condensation

[0038] Inhale butanol, 1.4-dihydroxyanthraquinone, and p-toluidine into the condensation reactor, stir at 50r / min for 10min, then put in hydrochloric acid, boric acid and catalyst, stir at 80r / min, and stir for 10min. Internally adjust the micro-positive pressure to 0.06MPa, heat up to 100-120°C, and keep warm for 4 hours (the heat preservation stage is di...

Embodiment 3

[0047]A kind of plastic coloring agent violet B, described violet B is made from violet B crude product and methanol; Wherein, described violet B crude product is made up of 200 parts of 35% butanol, 250 parts of 1,4-dihydroxyanthraquinone in parts by weight , 106 parts of p-toluidine, 120 parts of 35% hydrochloric acid, 65 parts of boric acid and 79 parts of catalyst are made; the ratio of the methanol and the crude product of purple B is 4:1 by weight; the methanol is 40% concentration Methanol.

[0048] A kind of preparation method of plastic colorant purple B, concrete steps are as follows:

[0049] (1) condensation

[0050] Inhale butanol, 1.4-dihydroxyanthraquinone, and p-toluidine into the condensation reactor, stirring at a speed of 60r / min for 5min, then put in hydrochloric acid, boric acid and a catalyst, stirring at a speed of 90r / min for 5min, and the reaction kettle Internally adjust the micro positive pressure to 0.08MPa, heat up to 100-120°C, and keep warm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com