Plastic colorant GG orange and preparation method thereof

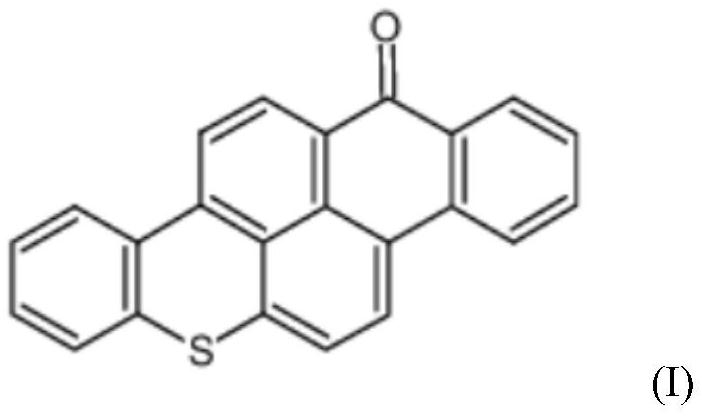

A technology for colorants and plastics, applied in the field of plastic colorants and their preparation, can solve the problems of reduced product purity, high reaction temperature, poor hue, etc., and achieve the effects of high product purity, uniform reaction and good properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

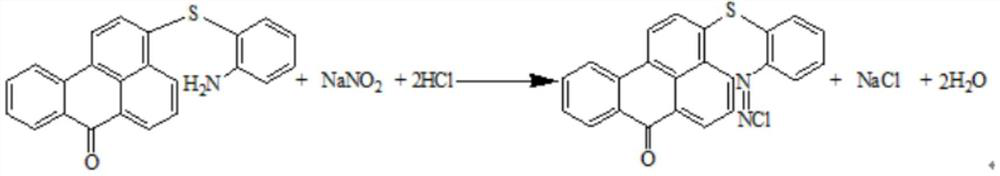

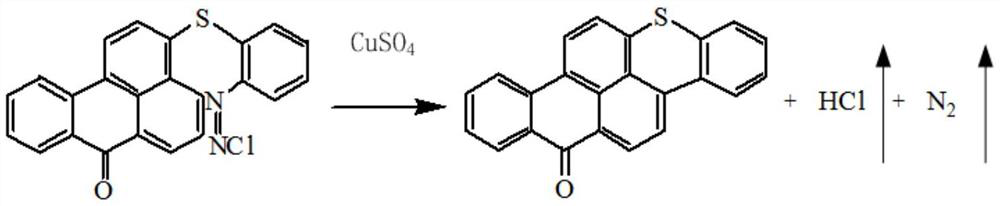

Method used

Image

Examples

Embodiment 1

[0030] A kind of plastic colorant GG orange is prepared from the following raw materials in parts by weight:

[0031] 800 parts of N,N-dimethylformamide, 195 parts of hydrochloric acid, 108 parts of water, 235 parts of 3-(2-aminophenylmercapto)benzoanthrone, 47 parts of 30% sodium nitrite aqueous solution, catalyst copper catalase 0.8 servings.

[0032] A kind of preparation method of plastic coloring agent GG orange, concrete steps are as follows:

[0033] (1) Weigh N, N-dimethylformamide, hydrochloric acid and 1 / 4 water into the reaction kettle in sequence, and then put 3-(2-aminophenylmercapto) benzoanthrone into the reaction kettle. Pass frozen brine through the jacket to lower the temperature in the reactor to 5°C, then add sodium nitrite aqueous solution to the reactor dropwise, the rate of addition is slow first and then fast, and the amount of addition is 25-50kg / h. Insulate and react at 15°C for 2 hours, press filter to obtain the filtrate for later use;

[0034] (...

Embodiment 2

[0038] A kind of plastic colorant GG orange is prepared from the following raw materials in parts by weight:

[0039] 780 parts of N,N-dimethylformamide, 200 parts of hydrochloric acid, 105 parts of water, 240 parts of 3-(2-aminophenylmercapto)benzoxanthrone, 50 parts of 28% sodium nitrite aqueous solution, catalyst copper catalase 0.6 parts.

[0040] A kind of preparation method of plastic coloring agent GG orange, concrete steps are as follows:

[0041] (1) Weigh N, N-dimethylformamide, hydrochloric acid and 1 / 5 water into the reaction kettle in sequence, and then put 3-(2-aminophenylmercapto) benzoanthrone into the reaction kettle. Pass frozen brine through the jacket to lower the temperature in the reactor to 6°C, then add sodium nitrite aqueous solution to the reactor dropwise, the rate of addition is slow at first and then fast, and the amount of addition is 25-50kg / h. Insulate and react at 10°C for 2.5 hours, press filter to obtain the filtrate for later use;

[0042...

Embodiment 3

[0046] A kind of plastic colorant GG orange is prepared from the following raw materials in parts by weight:

[0047] 820 parts of N,N-dimethylformamide, 190 parts of hydrochloric acid, 110 parts of water, 230 parts of 3-(2-aminophenylmercapto)benzoanthrone, 45 parts of 32% sodium nitrite aqueous solution, catalyst copper catalase 0.9 servings.

[0048] A kind of preparation method of plastic coloring agent GG orange, concrete steps are as follows:

[0049] (1) Weigh N,N-dimethylformamide, hydrochloric acid and 1 / 3 water into the reaction kettle in sequence, and then put 3-(2-aminophenylmercapto)benzenthrone into the reaction kettle. Pass frozen brine through the jacket to lower the temperature in the reactor to 3°C, then add sodium nitrite aqueous solution to the reactor dropwise, the rate of addition is slow first and then fast, and the amount of addition is 25-50kg / h. Insulate and react at 20°C for 1.5 hours, press filter to obtain the filtrate for later use;

[0050] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com