Wind turbine generator overhead rail type cabin inspection system

A technology for wind turbines and inspection systems, which is used in the monitoring of wind turbines, machines/engines, and wind turbines, can solve problems such as large demand for personnel, high costs, and limited space in the engine room, so as to improve the level of automation and ensure reliability. , the effect of reducing the staff on duty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

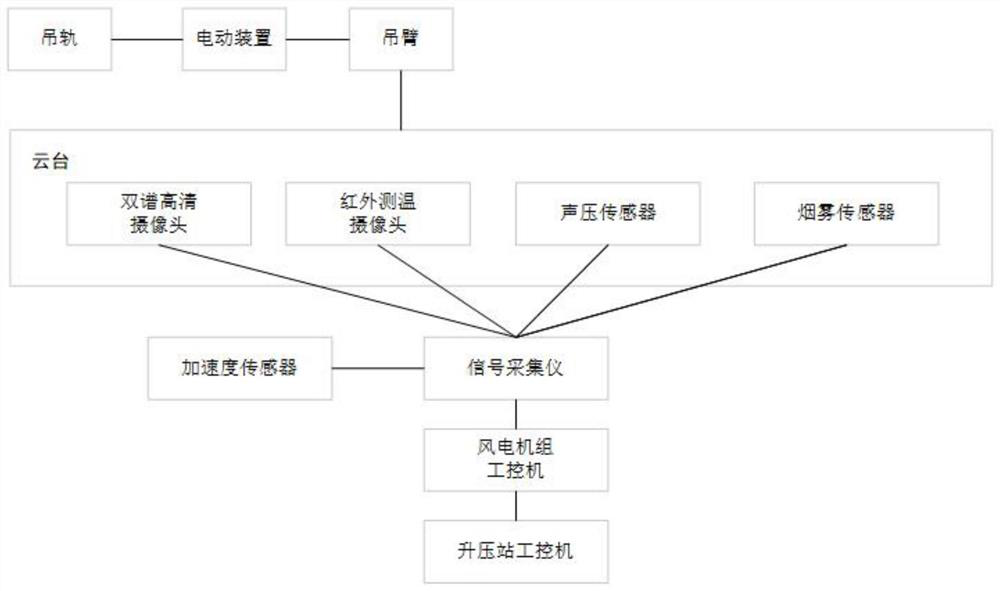

[0018]Participatefigure 1As shown, this embodiment provides a hanging rail nacelle inspection system for wind turbines, which includes a hanging rail arranged in the nacelle of the wind turbine, and the hanging rail is connected with a boom; the boom is driven by an electric device and can move along the hanging rail , And realize the telescopic and rotational movement in the vertical direction;

[0019]The boom is connected with a camera pan / tilt, and the camera pan / tilt is fixedly installed with a bispectral high-definition camera and an infrared temperature measurement camera for video monitoring and temperature measurement of the parts in the cabin;

[0020]The inspection system also includes a sound pressure sensor, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com