Induction cooker with ultrasonic cleaning function

A technology of ultrasonic and induction cooker, applied in the field of induction cooker with ultrasonic cleaning function, can solve the problem of single function of induction cooker, and achieve the effect of solving high cost problem, reducing cost and solving single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

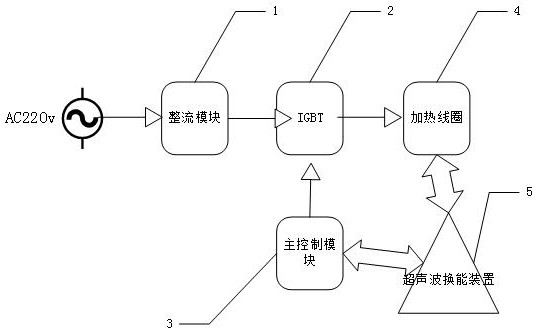

[0022]Such asfigure 1 , The induction cooker with new ultrasonic cleaning function includes rectifier module 1, IGBT module 2, main control module 3, heating coil 4, and ultrasonic transducer 5.

[0023]The working frequency of the present invention is set atTo prevent the IGBT module from overheating, replace the original model H20R1203 with H25R1203, the rectifier module 1 is KBJ2510, the ultrasonic transducer 5 is a 50W industrial vibrator of a certain brand, and the main control module 3 uses an 8-bit monolithic microcontroller such as EM78P156EILP, the inductance of the heating coil 4 is 130uH.

[0024]Working principle: 220v mains power is rectified into 300V direct current by rectifier module 1, IGBT module 2 converts 300V direct current into high-frequency pulse direct current under the control of main control module 3, heating coil 4 and corresponding capacitor form a resonance circuit, and pulse direct current It is converted into high-frequency alternating current. The high-fre...

Embodiment 2

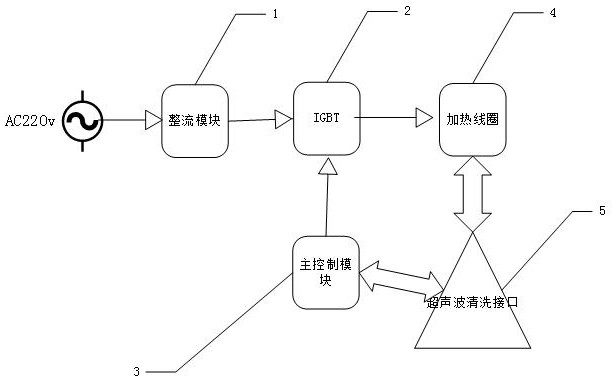

[0027]Such asfigure 2 , The induction cooker with new ultrasonic cleaning function includes rectifier module 1, IGBT module 2, main control module 3, heating coil 4, ultrasonic cleaning equipment interface 5, the above 1, 2, 3, 4 are shared by electromagnetic heating function and ultrasonic cleaning function Module. The 5 is a reserved interface.

[0028]The main control module 3 uses an 8-bit monolithic microcontroller GMS87C1202 with 2KROM. Ultrasonic cleaning equipment interface 5 is a prefabricated interface, which can be used for external ultrasonic transducers that meet the requirements, such as ultrasonic vegetable washing tanks and ultrasonic dishwashers. The working frequency is set at.

Embodiment 3

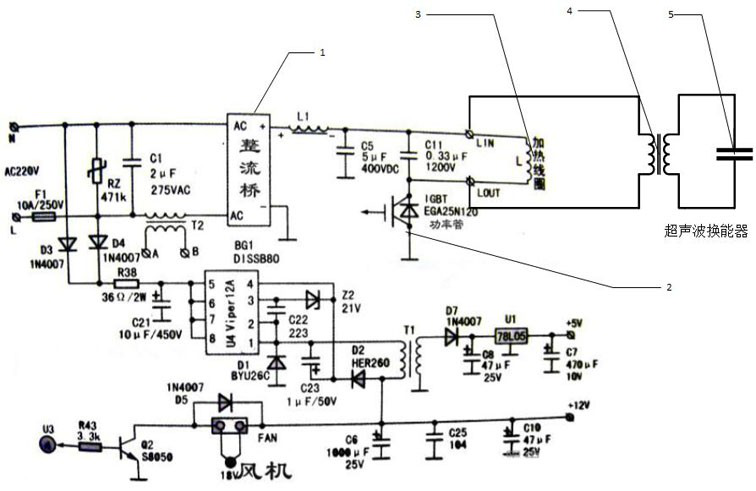

[0030]Such asimage 3, Is a basic circuit diagram of the present invention. The induction cooker with new ultrasonic cleaning function includes a rectifier module 1, an IGBT module 2, a heating coil 3, an isolation transformer 4, an ultrasonic transducer 5, and other auxiliary circuits.

[0031]The rectifier module 1 is KBJ2510, the model of the IGBT module 2 is EGA25N120, the inductance of the heating coil 3 is 130uH, and the ultrasonic transducer 5 is a 50W industrial vibrator of a certain brand, and the operating frequency is set at, The transformation ratio of isolation transformer 4 is 1:1.

[0032]The working principle is: 220v city power is rectified into 300V direct current by rectifier module 1, IGBT module 2 converts 300V direct current into pulsed direct current under the control of the main control module, heating coil 3 and capacitor form a resonance circuit to convert pulsed direct current into high The high-frequency alternating current generates a magnetic field through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com