Waste heat recovery equipment for grain dryer processing

A technology of waste heat recovery equipment and grain dryer, which is applied in lighting and heating equipment, drying, grain drying and other directions, can solve the problems of different heat, incomplete heat recovery, and inability to change the hot air velocity, etc., to improve the effect, The effect of improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

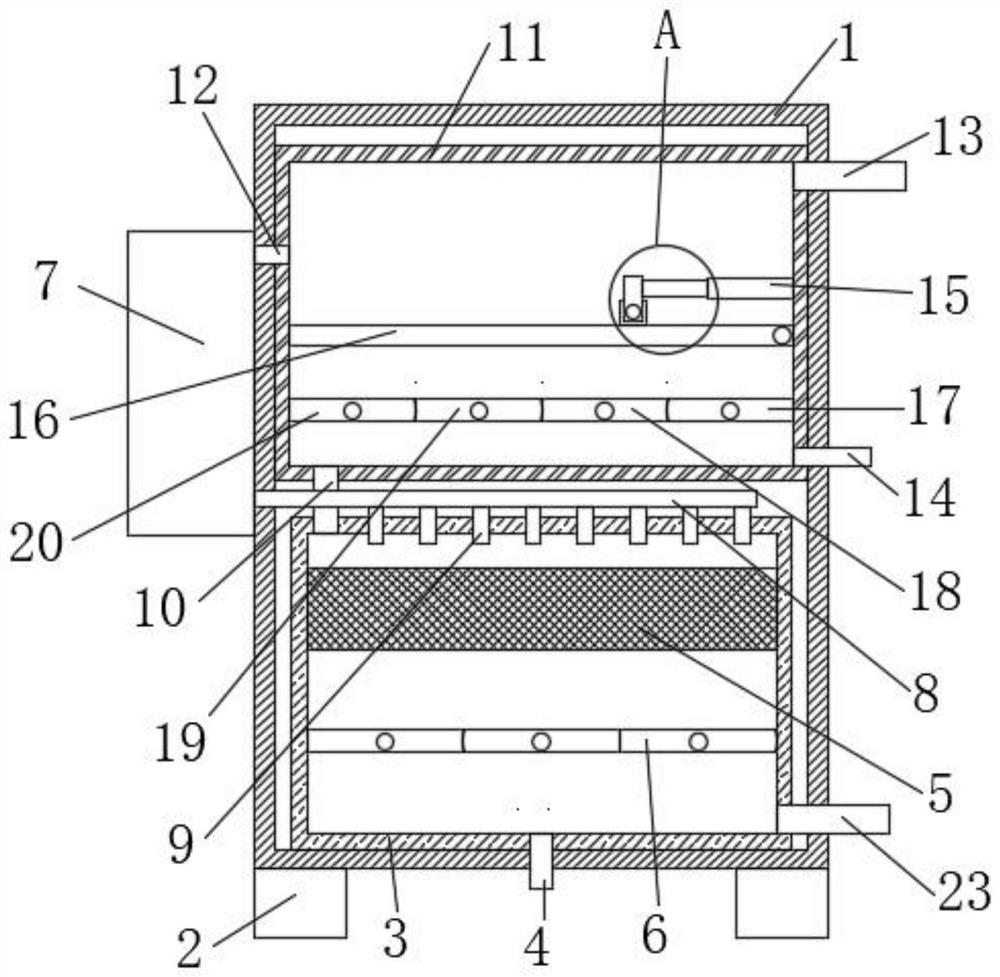

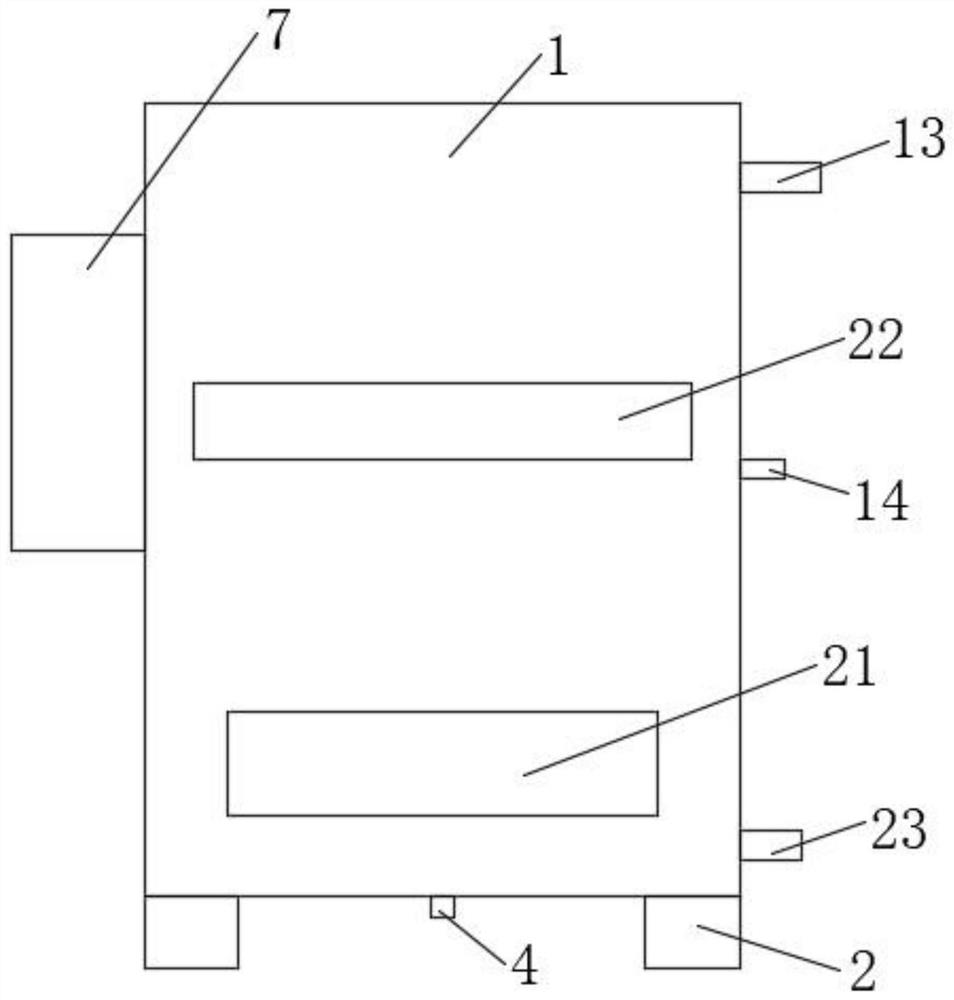

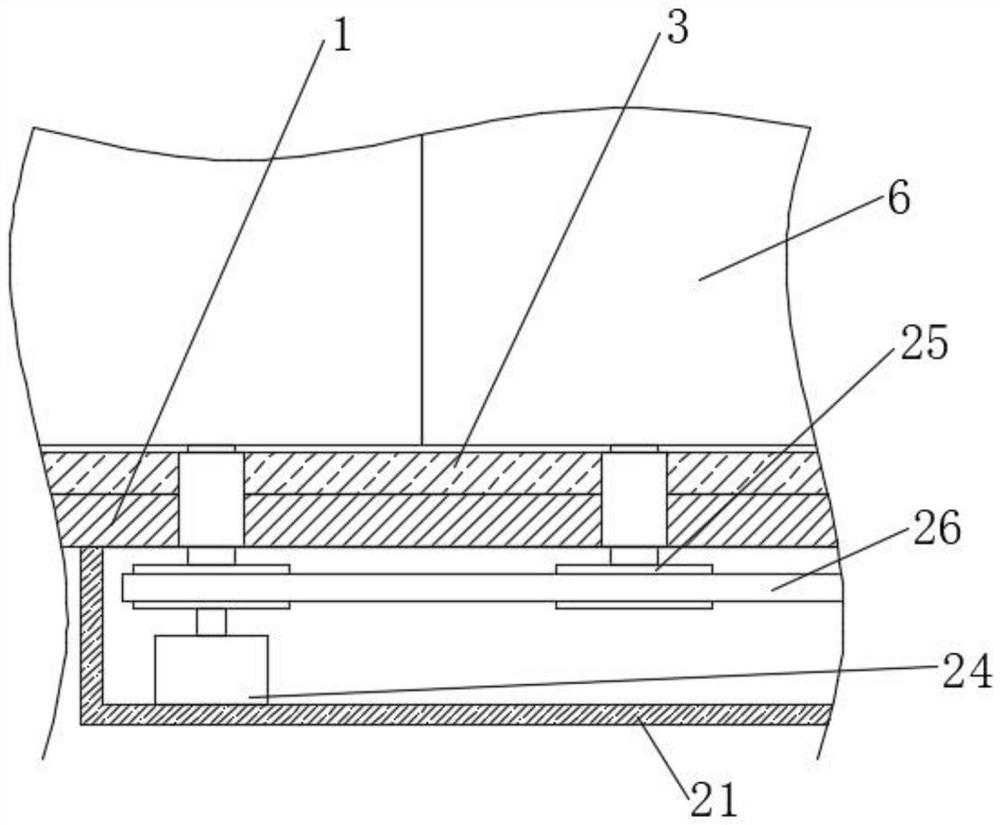

[0028] Such as Figure 1-5 As shown, the embodiment of the present invention provides a kind of waste heat recovery equipment for grain dryer processing, including a box body 1 and a fixed base 2, the inner bottom wall of the box body 1 is fixedly connected with a dust removal box 3, and the bottom of the dust removal box 3 is connected with a Sewage pipe 4, the interior of dust removal box 3 is fixedly connected with activated carbon layer 5, one side of dust removal box 3 is communicated with air intake pipe 23, and the inside of dust removal box 3 is connected with a plurality of dust removal plates 6 through rotating shaft rotation, and a plurality of dust removal plates 6 all Located below the activated carbon layer 5, the inside of the box body 1 is fixedly connected with a recovery box 11, one side of the recovery box 11 is connected with an exhaust pipe 13, one side of the recovery box 11 is connected with a drain pipe 14, and the inside of the recovery box 11 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com