Amorphous silicon solar cell panel hardness tester

A solar panel and tester technology, applied in the field of solar cells, can solve problems such as low efficiency, inaccuracy, and human factors, and achieve the effects of improving testing efficiency, ensuring accuracy, and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

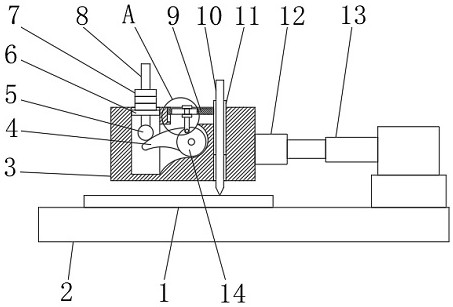

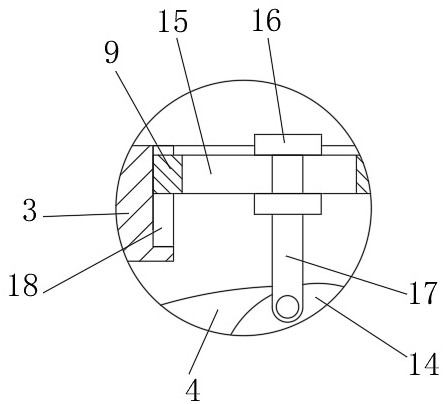

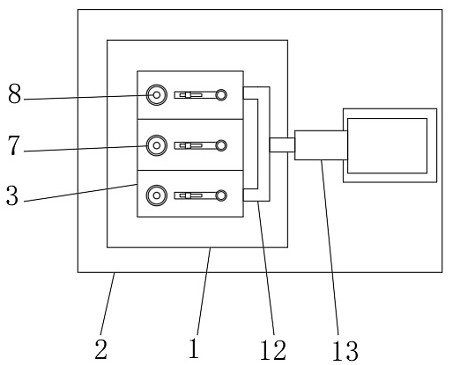

[0024] Embodiment one: refer to Figure 1~4 , in an embodiment of the present invention, an amorphous silicon solar panel hardness tester includes a workbench 2 on which a battery panel 1 is placed, and a telescopic device 13 is placed on the right part of the upper end of the workbench 2 to provide The power source, the output end of the expansion device 13 is connected to the connection plate 12, and the end of the connection plate 12 away from the expansion device 13 is fixedly connected with a plurality of test main blocks 3, which can realize the synchronous movement of multiple test main blocks 3 in a single time, and the test main block 3 The left end of the interior is connected with a receiving plate 6 for movement, and the receiving plate 6 is fixedly arranged on the limit shaft 8. The lower end of the limit shaft 8 is fixedly connected with the ball head block 5, and the side end of the ball head block 5 is extruded and contacted with the arc block 4. The head block...

Embodiment 2

[0031] Embodiment 2: This invention also provides another embodiment, which is improved on the basis of the above embodiment, the left end of the limiting plate 9 is moved and connected to the card set inside the test main block 3 In the connecting groove 18, restraint support to the limiting plate 9 is realized.

[0032] To sum up, when the invention is working, by placing the battery board 1 on the workbench 2, starting the telescopic device 13, and moving the test main body block 3 to the position above the battery board 1, at this time, multiple test main body blocks 3 Different numbers of weights 7 are placed on the limit shaft 8, and the ball head block 5, the arc block 4, and the turntable 14 are driven to realize the downward movement of the swing rod 17 at the side end, and the pencil in the clamping part 11 is driven by the limit rod. 10 moves down, so far start the telescopic device 13, so that multiple test main blocks 3 move synchronously, realize multiple hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com