Technical field of tea leaf fixation machine structure optimization devices based on discrete element principle

A technology of optimizing device and fixing machine, which is applied in multi-objective optimization, design optimization/simulation, image data processing and other directions, and can solve the problem of not analyzing the change of the temperature field of the drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

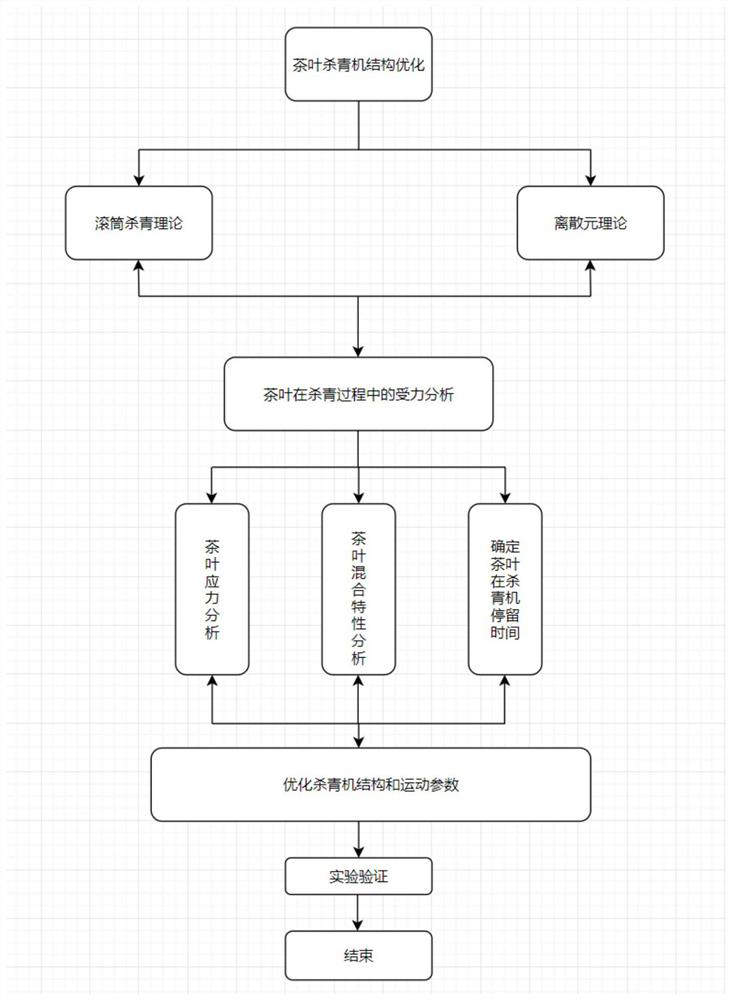

[0049] Step S1, determine the movement characteristics, stress situation and temperature change of the murderous leaves during the use of the killing machine;

[0050] Step S2, use the orthogonal table method to comprehensively evaluate the structure and motion parameters of the drum degreening machine, such as the drum speed, the number and distribution of the guide vanes, and the shape of the guide vanes, and carry out the experimental optimization of three factors and three levels, in which the shape of the guide vanes is selected as two Level, and then by tracking the movement, temperature and force of the green leaves, the results are obtained;

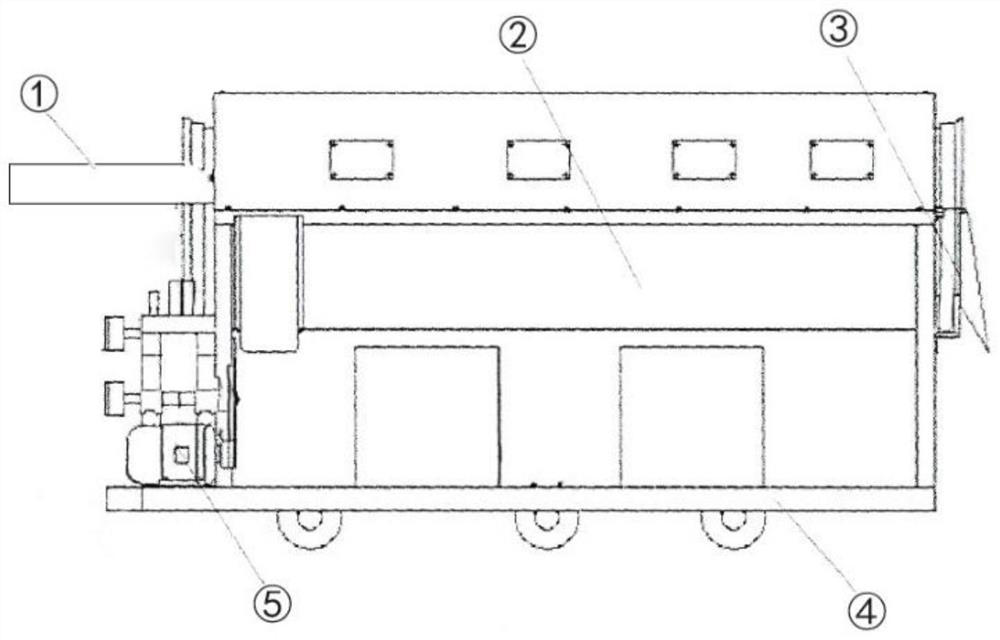

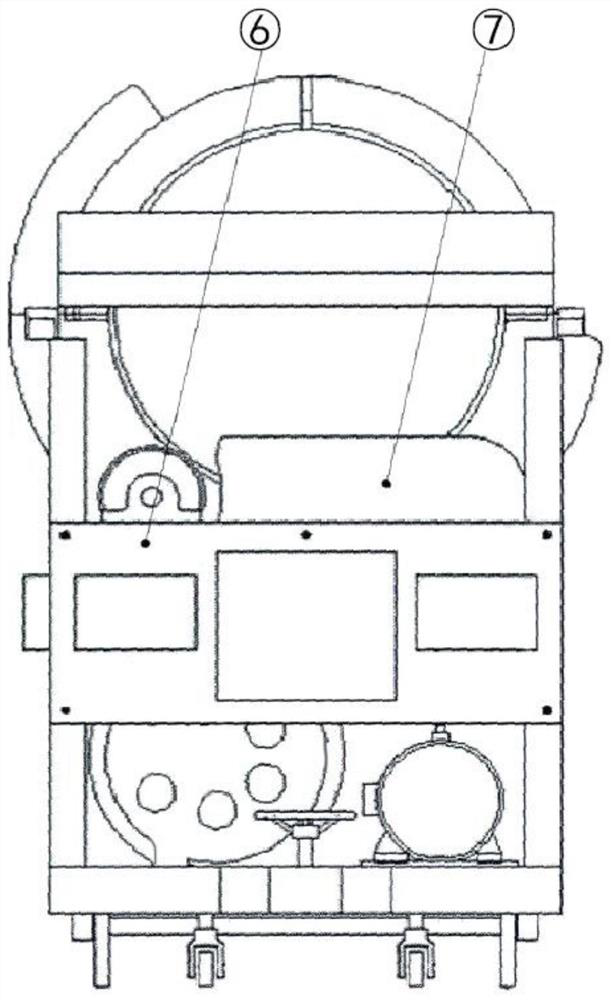

[0051] Step S3, such as Figure 4 As shown, the modeling software used is CATIA, and the three-dimensional model of the tea conveying device, barrel and transmission mechanism of the greening machine is constructed;

[0052] Further, if figure 2 , image 3 As shown, the diameter of the cylinder is 500mm, the length is 2000mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com