Light-emitting diode device and preparation method thereof

A technology of light-emitting diodes and devices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as stress marks and cracks in semiconductor epitaxial layers, and achieve the effects of reducing continuous accumulation, improving product quality, and reducing the area of epitaxial layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

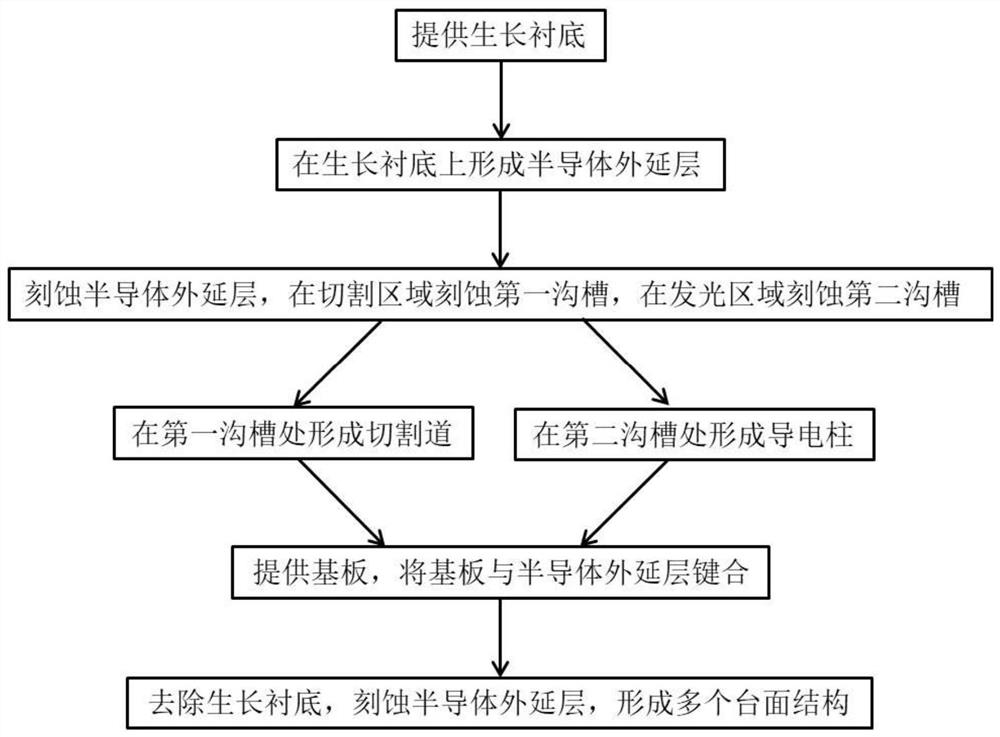

[0062] This embodiment provides a method for preparing a light-emitting diode device, referring to Figure 1 to Figure 9 , the method includes the following steps:

[0063] S1. Provide an epitaxial substrate 100; the epitaxial substrate 100 includes a sapphire patterned substrate, a sapphire substrate, a gallium nitride substrate, an aluminum nitride substrate, a silicon carbide substrate or a silicon substrate, etc., in this embodiment Among them, the epitaxial substrate 100 is specifically a sapphire patterned substrate or a sapphire flat substrate;

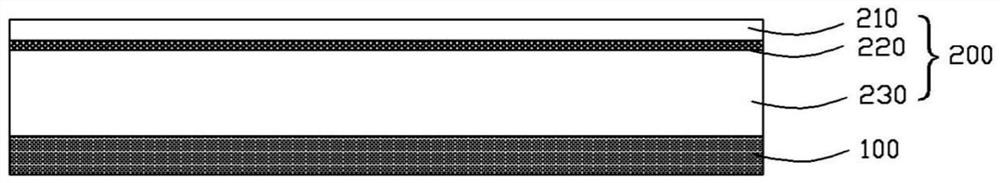

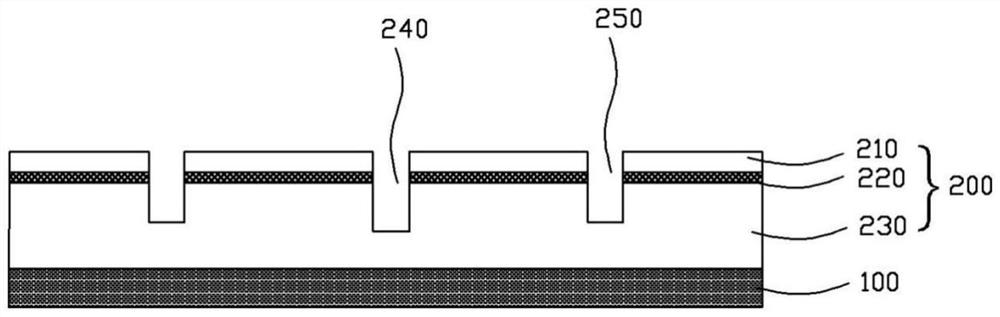

[0064] S2, such as figure 2As shown, a semiconductor epitaxial layer 200 is formed on an epitaxial substrate 100; the semiconductor epitaxial layer 100 includes a first type semiconductor layer 210, an active region 220 and a second type semiconductor layer 230 from top to bottom. In this embodiment, The first type semiconductor layer 210 is a P-type semiconductor layer, the second type semiconductor layer 230 is an N-type s...

Embodiment 2

[0076] The same example of this embodiment provides a method for manufacturing a light-emitting diode device. The similarities between this embodiment and Embodiment 1 will not be repeated. The difference is that the first groove 240, the second groove 250 and the third groove The etching sequence of the groove 260 is different, specifically:

[0077] In step S3, the semiconductor epitaxial layer 200 is etched, the semiconductor epitaxial layer 200 includes a light emitting region and a cutting region between the light emitting regions, and the semiconductor epitaxial layer 200 is etched between the light emitting region and the cutting region of the semiconductor epitaxial layer 200 The third groove 260, the third groove 260 independently divides the semiconductor epitaxial layer 200 into a light emitting diode mesa 280 located in the light emitting area and a cutting area mesa 270 located in the cutting area, and the light emitting diode mesa 280 and the cutting area mesa 270...

Embodiment 3

[0081] This embodiment has multiple same features as Embodiment 1 or Embodiment 2, and the difference between this embodiment and Embodiment 1 or Embodiment 2 is:

[0082] Step S7: Do not etch or partially etch the semiconductor epitaxial layer 200 of the mesa 270 in the cutting area, and retain the semiconductor epitaxial layer 200 at the cutting line 241 or in the space between the cutting line 241 and the light emitting region. Here, for the same The characteristics are no longer described one by one, only the differences are described.

[0083] An embodiment of the present invention provides a method for fabricating a light emitting diode device. In step S7, the epitaxial substrate 100 is removed, and a third layer penetrating through the semiconductor epitaxial layer 200 is etched between the light emitting region and the cutting region of the semiconductor epitaxial layer 200. Groove 260, the third groove independently divides the semiconductor epitaxial layer 200 into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com