Disposable thin-film apron and production method thereof

A disposable, thin-film technology, applied in clothing, protective clothing, applications, etc., can solve problems such as unclean cleaning, achieve low moisture permeability, reduce production costs, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

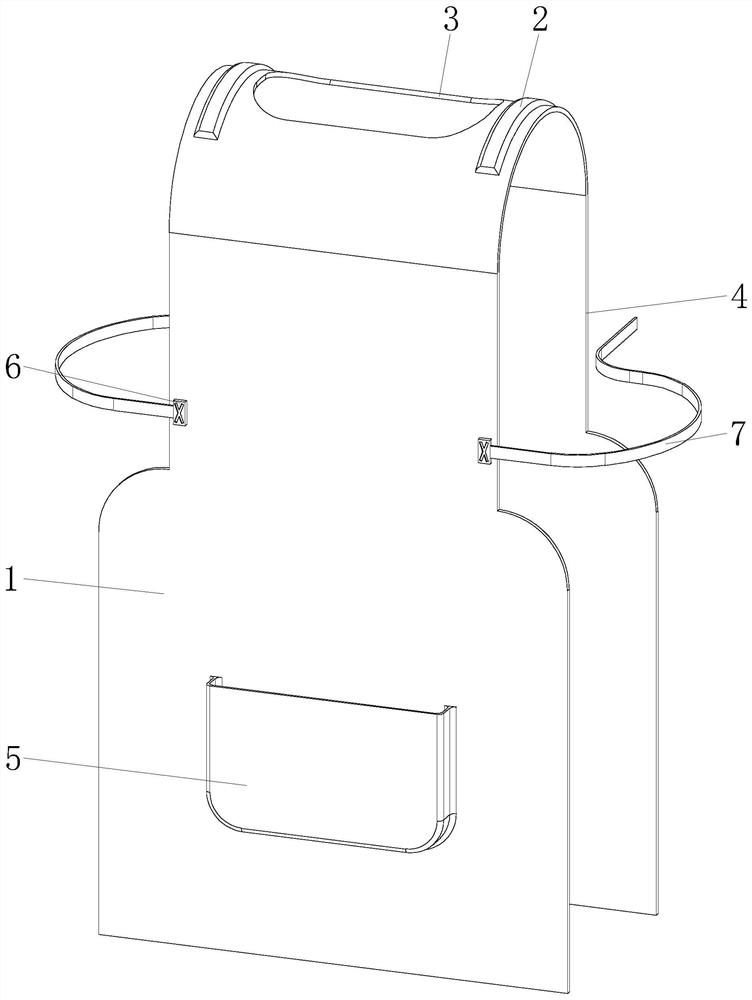

[0027] see Picture 1-1 , the present invention provides a technical solution: a disposable film apron, comprising a film apron body 1, the top of the film apron body 1 is fixedly equipped with a reinforcement shoulder strap 2, the top of the film apron body 1 is provided with a neck groove 3, the film apron body 1 The left and right sides of the body 1 are provided with shoulder grooves 4, the front of the film apron body 1 is fixedly installed with a film pocket 5, and the front of the film apron body 1 is fixedly installed with a hot melt block 6, and one side of the hot melt block 6 is fixedly installed There is a film belt7.

[0028] In the scheme of this embodiment, the film apron body 1 made of PE film material has moisture resistance and low moisture permeability, and low-density, medium-density or high-density PE films can be used to manufacture film aprons with different densities. The density of low-density PE film is about 0.92g / cm3. Low-density polyethylene film ...

Embodiment 2

[0030] Such as Picture 1-1 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: there are two reinforced shoulder straps 2, and the two reinforced shoulder straps 2 are symmetrically installed on the top of the film apron body 1, and the neck groove 3 is opened in the On the top of the film apron body 1 , the neck groove 3 is located between the two reinforced shoulder straps 2 .

[0031]In this embodiment, the two reinforced shoulder straps 2 are symmetrically installed on the top of the film apron body 1, which can greatly increase the stress on the shoulders of the apron and greatly improve the durability of the apron. The material of the reinforced shoulder straps 2 is cross Linked polyethylene, the material has higher heat resistance, tensile strength, heat shrinkage and barrier properties, and is set on the top of the film apron body 1 through the neck groove 3, so that the device can be conveniently placed on the user's body On ...

Embodiment 3

[0033] Such as Picture 1-1 As shown, the present invention provides a technical solution on the basis of Embodiment 1 and Embodiment 2: there are two shoulder grooves 4, and the two shoulder grooves 4 are symmetrically opened on the left and right sides of the film apron body 1, and the film The left side and the right side of pocket bag 5 are fixedly installed together with film apron body 1 respectively, and the bottom of film pocket bag 5 is fixedly installed together with film apron body 1.

[0034] In this embodiment, two shoulder grooves 4 are symmetrically opened on the left and right sides of the film apron body 1, so that the shoulders on both sides of the user can pass through so that the user can wear it. and the right side are respectively fixedly installed together with the film apron body 1 and the bottom of the film pocket 5 is fixedly installed together with the film apron body 1, so that it is convenient for the user to put the required articles into it durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com