High-water-resistance gypsum-based decorative mortar and preparation method thereof

A decorative mortar and water-resistant technology, applied in the field of building materials, can solve the problems of fast setting time, high water absorption, water resistance, etc., and achieve the effect of improving water retention, high softening coefficient and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

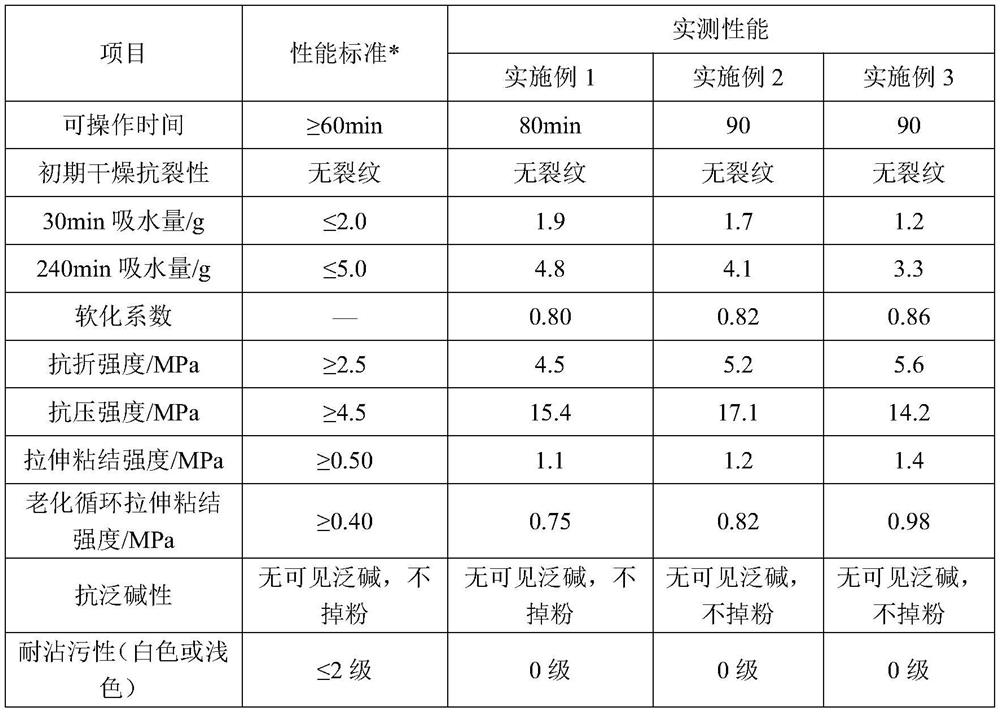

Examples

preparation example Construction

[0038] The preparation method of highly water-resistant gypsum-based decorative mortar comprises the following steps:

[0039] Step 1, weighing various raw materials according to weight ratio.

[0040] Step 2, add the weighed gypsum, aluminate cement and slag fine powder together into a twin-shaft horizontal mixer and mix for 1min-2min.

[0041] Step 3, add the weighed latex powder, cellulose ether, retarder, defoamer, water repellent and inorganic pigment into the twin-shaft horizontal mixer and continue mixing for 2min-4min.

[0042] Step 4: Add the weighed quartz sand into a biaxial horizontal mixer and mix for 2-3 minutes to prepare a highly water-resistant gypsum-based decorative mortar.

[0043] When in use, add water to the high water-resistant gypsum-based decorative mortar, the amount of water added is 15%-18% of the total weight of the high water-resistant gypsum-based decorative mortar. Put it into a forced mixer, and slowly add the required amount of water while ...

Embodiment 1

[0046] A high water-resistant gypsum-based decorative mortar, according to 100 parts of hemihydrate desulfurized gypsum, 8 parts of aluminate cement, 12 parts of slag micropowder, 6 parts of latex powder, 0.2 part of cellulose ether, 0.1 part of defoamer, water repellent 1 part, 1.2 parts of inorganic pigment, and 240 parts of quartz sand are configured by weight ratio.

[0047] First add the weighed gypsum, aluminate cement and slag micropowder into the double-shaft horizontal mixer and mix for 1min-2min, then add the weighed latex powder, cellulose ether, retarder, defoamer, hydrophobic Put the water agent and inorganic pigment together into the double-shaft horizontal mixer and continue mixing for 2min-4min, then add the quartz sand into the double-shaft horizontal mixer and mix for 2min-3min to obtain a high water-resistant gypsum-based decorative mortar.

[0048] Add water according to 18% of the total weight of the high water-resistant gypsum-based decorative mortar, and...

Embodiment 2

[0051] A high water-resistant gypsum-based decorative mortar, according to 100 parts of hemihydrate desulfurized gypsum, 15 parts of aluminate cement, 15 parts of slag micropowder, 8 parts of latex powder, 0.25 parts of cellulose ether, 0.3 parts of defoaming agent, water repellent 1.2 parts, 2.6 parts of inorganic pigment and 390 parts of quartz sand are configured by weight ratio.

[0052] First add the weighed gypsum, aluminate cement and slag micropowder into the double-shaft horizontal mixer and mix for 1min-2min, then add the weighed latex powder, cellulose ether, retarder, defoamer, hydrophobic Put the water agent and inorganic pigment together into the double-shaft horizontal mixer and continue mixing for 2min-4min, then add the quartz sand into the double-shaft horizontal mixer and mix for 2min-3min to obtain a high water-resistant gypsum-based decorative mortar.

[0053] Add water according to 15.5% of the total weight of the high water-resistant gypsum-based decorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com