Naphthalimide organic dye, electrowetting display ink and electrowetting display

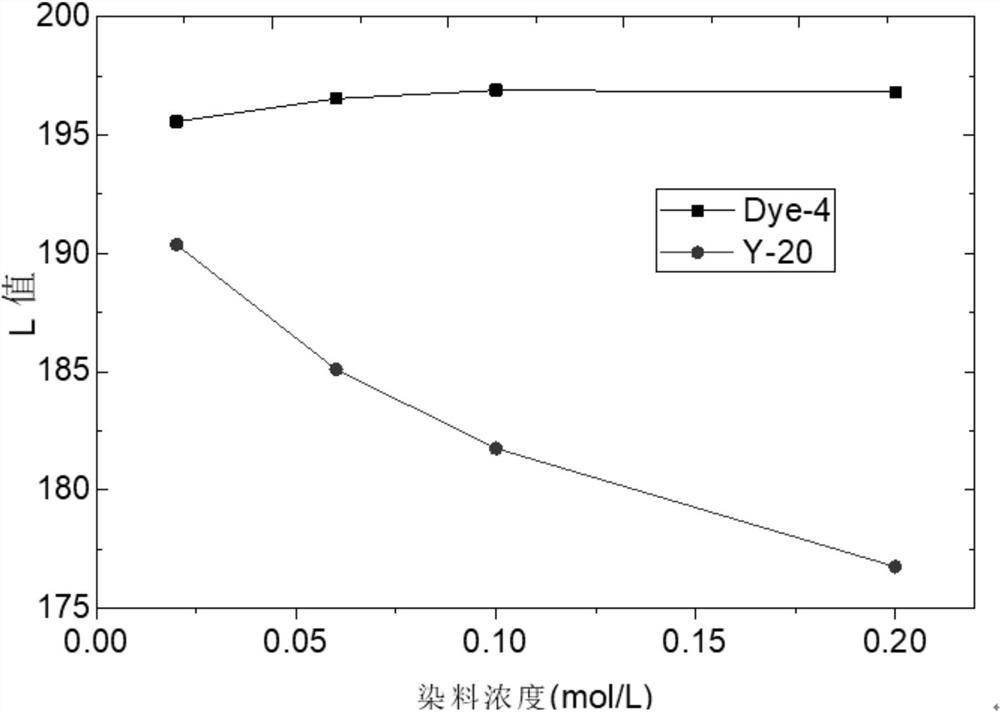

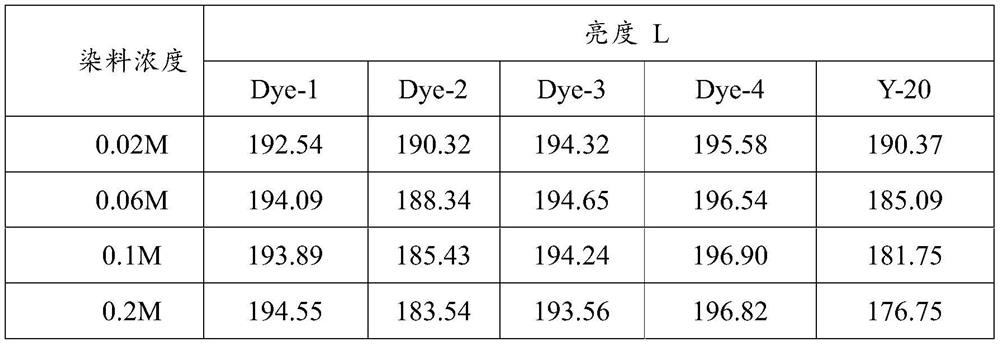

An electrowetting display and naphthalimide technology, applied in naphthalene dicarboxamide dyes/phthalimide dyes, inks, organic chemistry, etc., can solve the problems of improving energy consumption of display devices, low display contrast, and poor visual experience and other problems, to achieve the effect of excellent contrast, high solubility, and good visual experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

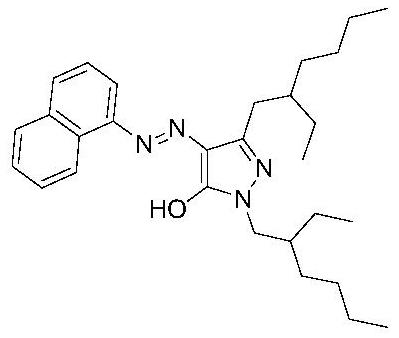

Method used

Image

Examples

Embodiment 1

[0030] Weigh 2.0g (7.22mmol, 277g / mol) 4-bromo-1,8-naphthoic anhydride Add it into a 50ml round bottom flask, measure 40ml of absolute ethanol as the reaction solvent, and heat up to 50 degrees Celsius. Weigh 3.7g (187g / mol, 0.02mol) 3-(2-ethylhexyloxy) propylamine Continue the reaction for 8h, remove the solvent by rotary evaporation, and pass through the column to obtain 3.08g colorless oily intermediate 1 Yield 95.6%.

[0031] Weigh 1.5g (446g / mol, 0.00336mol) intermediate 1 Dissolve in 30ml ethylene glycol methyl ether, pipette 2ml piperidine The temperature was raised to 125 degrees Celsius to continue the reaction for 12 hours. 1.2g of yellow-green dye 1 was obtained through the column, (Dye-1), yield 80%.

[0032] NMR characterization data: 1 H NMR (400MHz, CDCl 3 ):δ=8.558-8.546(d, J=4.8Hz, 1H), δ=8.485-8.471(d, J=5.6Hz, 1H), δ=8.380-8.366(d, J=5.6Hz, 1H), 7.669-7.643(t, J=10.4Hz, 1H), 7.167-7.151(d, J=6.4Hz, 1H), 4.272-4.243(t, J=11.6Hz, 2H), 3.550-3.52...

Embodiment 2

[0034] Weigh 2.0g (7.22mmol, 277g / mol) 4-bromo-1,8-naphthoic anhydride Add it into a 50ml round bottom flask, measure 40ml diethylene glycol butyl ether as the reaction solvent, and heat up to 120 degrees Celsius. Weigh 7.4g (187g / mol, 0.04mol) 3-(2-ethylhexyloxy) propylamine The reaction was continued for 8h, the solvent was removed by rotary evaporation, and 4.2g of yellow-green dye 2 was passed through the column, (Dye-2), yield 75.6%.

[0035] NMR spectrum characterization data: 1 H NMR (400MHz, CDCl 3 ):δ=8.567(m,1H),8.429(m,1H),8.067(m,1H),7.525(m,1H),6.640(m,1H),6.465(m,1H),4.264-4.253( d, J=4.4Hz, 2H), 3.703(s, 2H), 3.554-3.508(d, J=18.4Hz, 4H), 3.389(s, 2H), 3.287(s, 2H), 2.098(s, 2H ),2.031(s,2H),1.439(s,2H),1.266(m,16H),0.905(m,12H). 13 C NMR (400MHz, CDCl 3 ):164.756,164.184,149.922, 134.612,130.996,129.829,126.327,124.327,123.064,120.318,103.753,74.764,73.747,71.247, 69.250,43.458,39.895,39.641,37.781,30.561,29.113,28.453,23.857,23.070, 14.127, 11.058. ...

Embodiment 3

[0037] Weigh 2.77g (0.01mmol, 277g / mol) 4-bromo-1,8-naphthoic anhydride Add it into a 50ml round bottom flask, measure 40ml of glacial acetic acid as the reaction solvent, and heat up to 50 degrees Celsius. Weigh 4.47g (149g / mol, 0.03mol) p-n-butylaniline The temperature was raised to reflux for 12 hours, the solvent was removed by rotary evaporation, and 2.5 g of colorless oily intermediate 1 was obtained by passing through the column. Yield 62.5%.

[0038] Weigh 1.5g (408g / mol, 0.00367mol) of intermediate 1, dissolve in 30ml of ethylene glycol methyl ether, pipette 2ml of piperidine Added to the above reaction solution, raised the temperature to reflux for 24h, passed through the column to obtain 1.2g of yellow dye 2, (Dye-3), yield 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com