Manufacturing method of wire rod for high-strength tire bead steel wire

A bead wire and manufacturing method technology, applied in the field of wire rod preparation, can solve the problems of unqualified torsion performance of bead wire, increase of steel wire production cost, environmental pollution, etc., and achieve the goal of reducing steel wire usage, satisfying strength and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

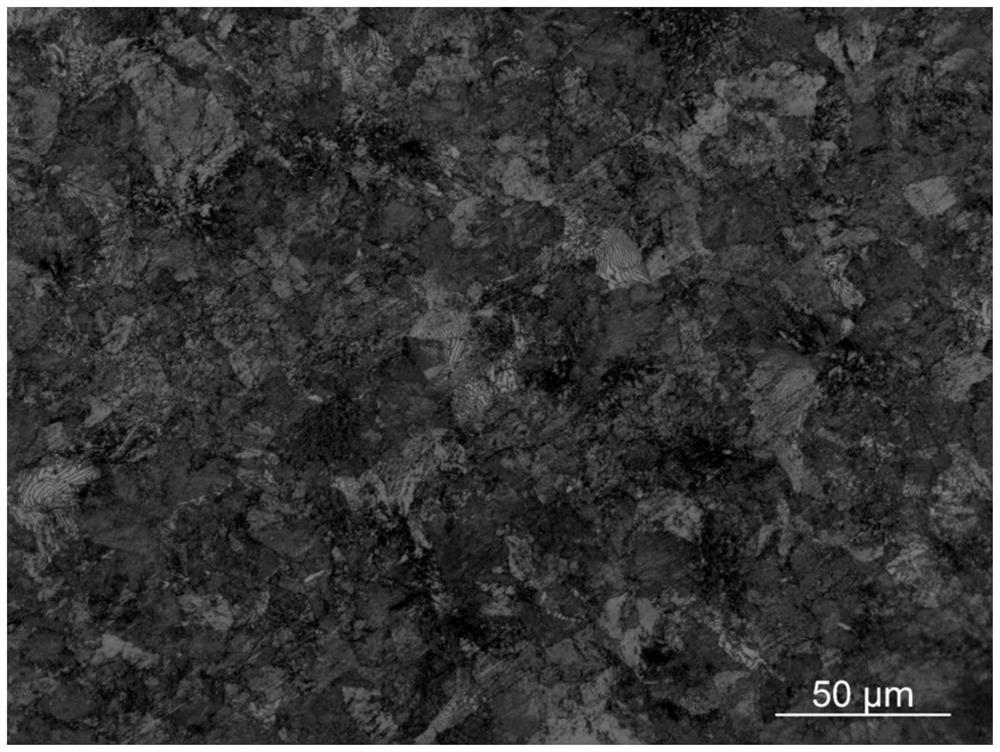

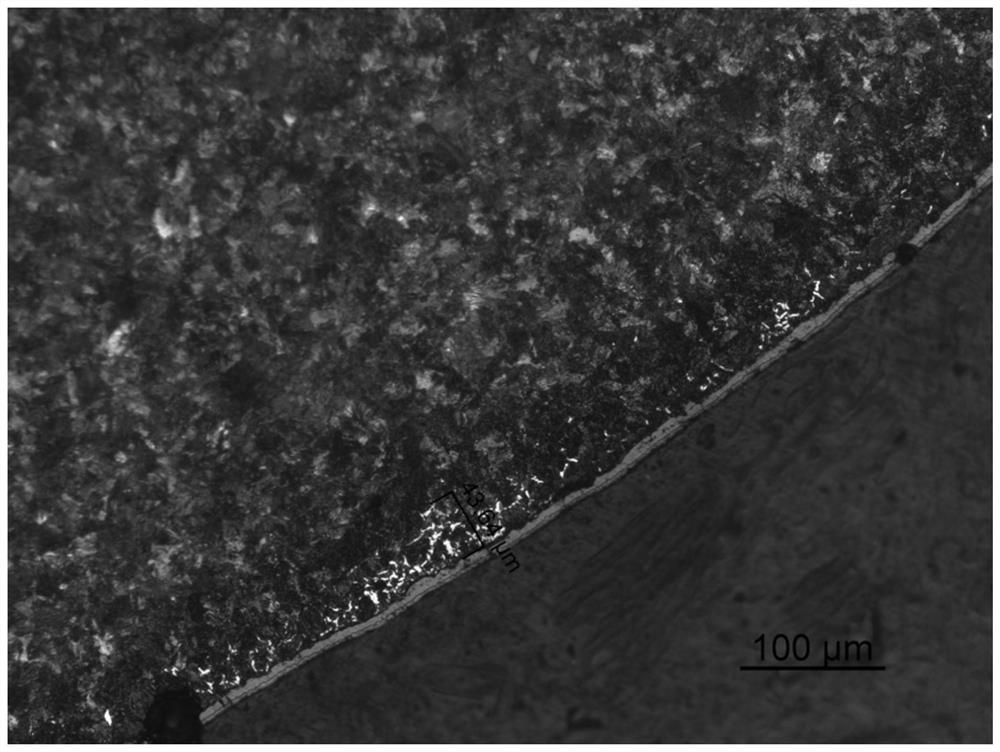

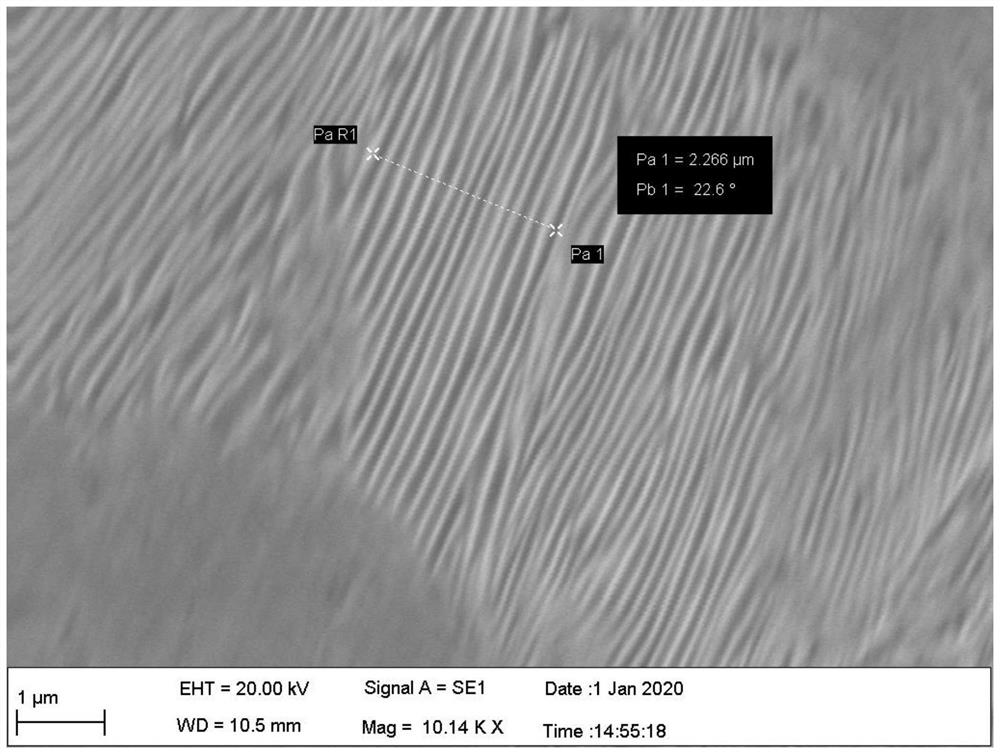

Image

Examples

Embodiment 1-4

[0038] Embodiment 1-4: a kind of preparation method of wire rod for high-strength bead wire, comprising the following steps:

[0039] 1. Composition design

[0040] The chemical composition design is calculated by weight percentage as C: 0.83-0.86%, Si: 0.18-0.22%, Mn: 0.52-0.58%, P≤0.015%, S≤0.010%, Al≤0.005%, the rest is Fe and others Unavoidable trace elements.

[0041] 2. Hot metal pretreatment

[0042] Add 340kg of lime desulfurizer to the molten iron tank, after KR pre-desulfurization, the S content of the molten iron is 0.002%, and remove the desulfurization slag.

[0043] 3. Converter smelting process:

[0044] The total loading capacity of the converter is 147 tons, including 112 tons of molten iron, 25 tons of scrap steel for cords, and 10 tons of pig iron. The tapping temperature of the converter is 1601°C, the tapping C is 0.15%, and the tapping P is 0.009%. After 90 seconds of tapping, 150kg of high-purity silicon carbide, 270kg of low-aluminum and low-titani...

Embodiment 1

[0060] In Example 1, component C is changed to 0.82%, Mn is changed to 0.50%, and other elemental components and process parameters remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com